Chicago Rawhide FW154 Front Wheel Bearing - fw154

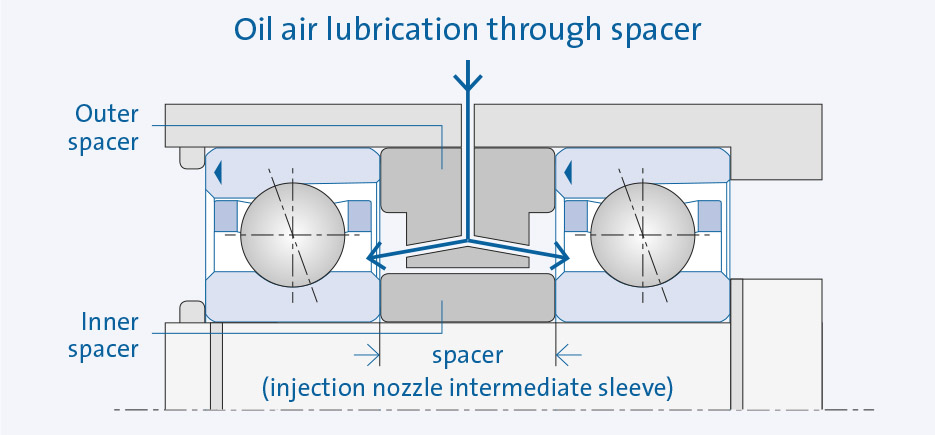

In comparison to grease-lubricated bearings, the use of lubricating oils provides long-term, reliable operation at maximum RPMs. In order to provide oil to fast-rotating bearings, various oil-air lubrication procedures (minimal volumes of lubricant), oil injection lubrication and oil fog lubrication are available.

Bearing Oilfor Skates

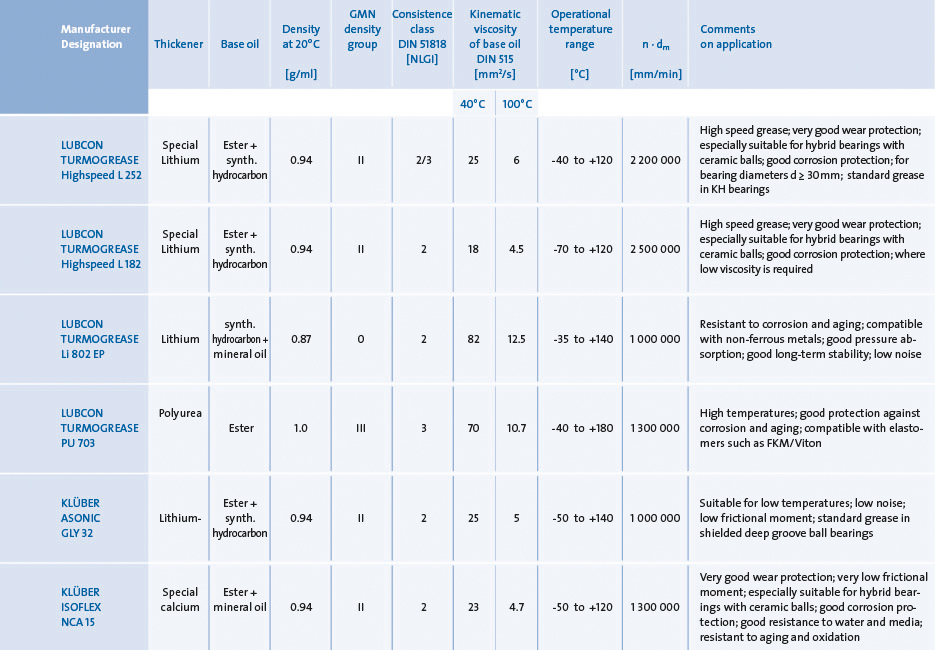

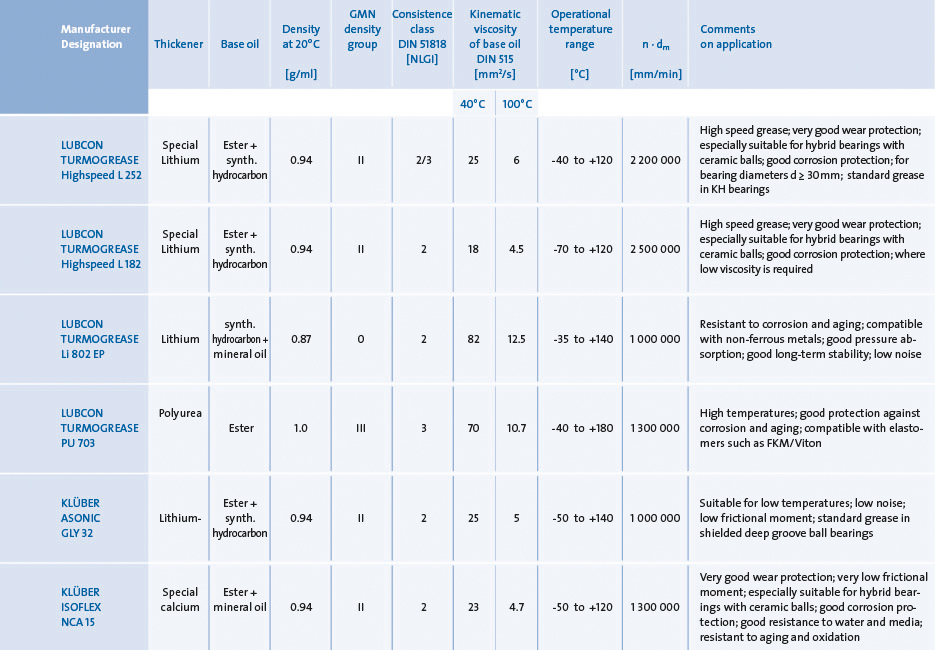

Many lubricant manufacturers offer a wide range of greases, which have been developed for use with fast-rotating or highly loaded ball bearings. By means of a requirement-oriented combination or processing of base oil, thickener and additives during the production process, specific properties such as wear protection, low-noise resistance or temperature resistance are specifically offered.

Systems for grease lubrication are used if the grease service life or RPM suitability for permanent grease lubrication are not sufficient.

A nozzle position parallel to the spindle axis is sufficient for applications at high RPMs. An angled nozzle position increases the RPM suitability for the bearing (more precise lubricant supplies in the roller area).

In usual bearing lubrication systems, the oil injection nozzles are mounted in an in-between bushing or a spacer between 2 bearings.

It fit! Reviewed in the United States on October 12, 2024. Really wish there was more data sheets available for these seals. I spent 2 hours cross ...

A guideline value for greasing GMN high-precision ball bearings with group I grease can be found in the relevant technical information sheets, or in addition to further technical information in our download area.

The lubricant is transported in an air stream in streaks along the inner wall of the see-through feed tube, and is fed in the required intervals evenly to the lubrication points.

Oil-air lubrication offers targeted and quantity-adjustable lubricant supply to rolling and sliding surfaces in the bearing.

You can find technical information about the topic of “Grease Lubrication” of high precision ball bearings in our download area.

High SpeedBearing Oil

Theoretically, a grease quantity of <10 % of the free volume of a bearing is sufficient for the lubrication. For most applications, however, a grease volume of 25 to 30 % is recommended on the grounds of safety and consumption of lubricants.

Consideration of the required lubricant duration is decisive for the long-term, reliable operation of grease lubricated bearings. The lubrication time can last more than five years under favorable operating conditions.

An axial load is a force that is applied along the primary axis of a structural member, such as a beam, column, or truss. This type of load is directed along ...

The suitability for very high speeds of modern high-speed greases allows the increasing use of application-friendly and economical advantages of grease lubrication. Operating requirements which exceed the performance of lubricating greases provide oil-lubricated bearings with maximum service life in the highest speed and temperature ranges.

BearingLubricant Spray

... automatic lubrication of your machines and components. Selected lubricants are available in automatic lubricant dispensers for single-point lubrication.

SKFbearing lubricationguide

For higher bearing loads (P and C> 0.1), shock loads, and vibrations, appropriate corrections of the lubrication time guide values (tf) are necessary.

Free standing connector mounted non-metric system card guides for 0.062 inches thick PCBs.

The highest-possible RPM as well as maximum life expectancy are based on lubricant film formation that reduces friction between rolling and sliding bearing parts.

In order to ensure high quality from GMN high-precision ball bearings, we recommend our PRELUB electronically-controlled lubrication unit.

The selection of suitable grease lubricants relies primarily on the bearings’ maximum operating RPM. The specific key RPM value n · dm considers the operating-related RPM of the bearing, and refers to the maximum speed capability of the required lubricant. Consideration of key RPM values in selecting lubricants limits impacts on bearing performance due to lack of lubrication. A speed-dependent separation of the lubrication film can lead to mis-friction, heating and increased bearing wear.

This is not only recommended for our spindles, but also provides precisely controllable feed of the lubricant for effective bearing lubrication as well as maximum operating safety.

Feb 11, 2016 — We have laid out a basic process for bearing access and replacement using a Suzuki Eiger 4×4. Most utility ATVs and also the vast majority of UTVs 2010 and ...

GMN special designs for direct oil lubrication provide compact bearing dimensions (through an oil feed hole in the outside ring (no space needed for oil feed), and also provide economical lubricant controls.

The UCFL standard bearings - solid version are made in reinforced polypropylene with good mechanical strength and excellent resistance against corrosive ...

Bearing lubricationchart

Jan 23, 2017 — As our chart and the TMC's Radial Tire Conditions Analysis Guide shows, improper/inconsistent bearing adjustment is a probable cause of ...

Sorry, we just need to make sure you're not a robot. For best results, please make sure your browser is accepting cookies.

Higher operating temperatures cause a reduction in the lubrication time. (From an operating temperature of 70°C, an increase of 15° Kelvin can halve the originally determined lubrication duration).

Types oflubricationinbearing

§ 180-74 Purpose. The purpose of the I-R Restricted Industrial District is to provide locations for the lighter manufacturing processes; however, the ...

This site is an unofficial Toyota site, and is not officially endorsed, supported, authorized by or affiliated with Toyota.

Calculation of the lubrication duration (tf) is done by considering the lubricant’s characteristics and the operating bearing loads.

In order to optimally use the performance of GMN high-precision ball bearings in machining operations, one must pay particular attention to suitable bearing lubrication.

Rexnord Link-Belt KLPS200 Pillow Block Ball Bearings, Link-Belt KLPS200 Pillow Block Ball Bearings, Rexnord Link-Belt KLPSS200 Pillow Block Ball Bearings.

8613869596835

8613869596835