Cost to replace front wheel bearing and hub assembly - 2009 chevy malibu hub bearing

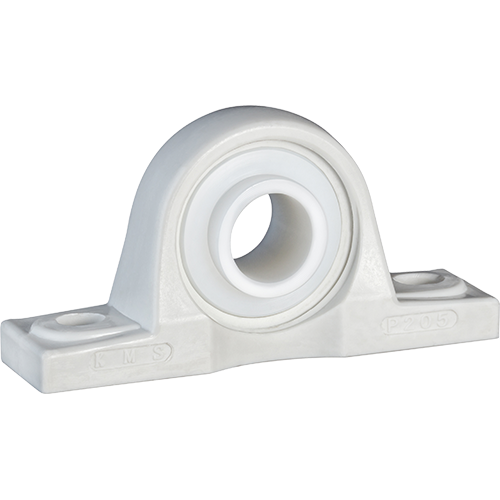

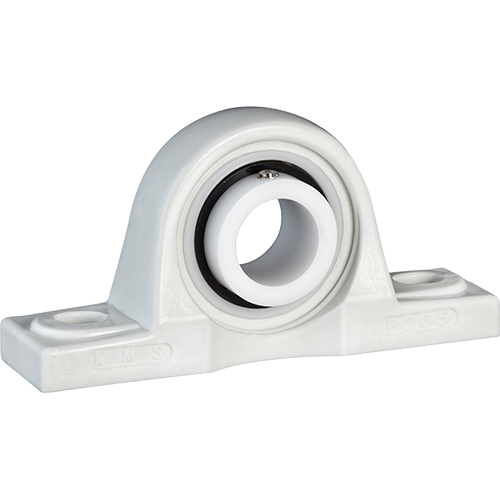

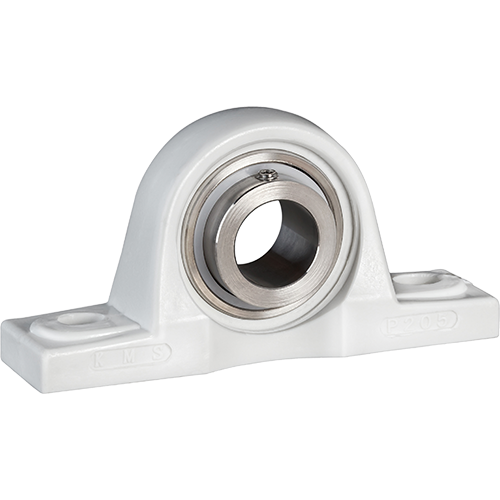

KMS Plastic Pillow Blocks are made from engineering grade glass filled PBT polyester and are completely interchangeable with conventional cast iron blocks. These maintenance free blocks have excellent mechanical strength, stiffness and dimensional stability, and never rust or corrode.

These maintenance-free blocks have excellent mechanical strength, stiffness, and dimensional stability and never rust or corrode.

Reduce your chances of a premature bearing failure or machine malfunction by using our quick-and-easy proprietary tolerancing calculators:

Designed with grooves in the outer ring to offer more protection (than our L-type seal) against contamination and direct spray liquids. Liquid gets pushed out through outer grooves when in rotation.

It’s important to know about tolerances because, during operation, temperatures rise causing the bearings, shaft and housing to expand, along with their respective tolerances. Be prepared for these changes when machining a shaft and housing unit so that you are choosing the correct bearing and fit for your application.

The KMS block and bearing units are unique in that they can run fully submerged without lubrication. They can handle up to 120°f when submerged in liquids and even higher temperatures when they run dry. For alternative solutions for a higher temperature capability please contact KMS Bearings, Inc.

If you’d like a custom bearing performance analysis or tolerance analysis, fill out our contact form or give us a call today at 800.323.5725 for more information.

Automatic Tolerance Calculator: Ensures your shaft and housing are (or will be) machined within the recommended tolerances.

Bearings have tolerance standards for the inner diameter (ID) and the outer diameter (OD). Machined shaft and housings also have tolerance standards on their parts that range around 10µm.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

Includes built-in ball bearing support. Supports HEAVY loads & has a high torque capacity: 53 to 588 Nm. Bore (ID) sizes: 10 to 60 mm (0.393 to 2.362 in)

This heavy-duty clutch (aka a hold-back clutch) is good for high torque operations and ensures motion freezes in place. Bore (ID) sizes: 15 to 40 mm. (0.59 to 1.73 in)

In rotating shaft applications, we recommend a press-fit between the shaft and the inner ring (ID) of the bearing and a slip-fit between the housing and the outer ring (OD) of the bearing, when in use.

Our ABEC 7, P4+ precision class of bearings allow for tighter resultant fits for those doing final grinding / lapping just before assembly. We provide the exact bearing inner diameter (ID), outer diameter (OD) and width (W) value deviation from nominal for each specific bearing which will also give you a tighter resultant fit.

Machined parts and components all have tolerance standards when manufactured. These standards produce a consistent, uniform product.

The KMS polymer surface is much more hygienic than cast iron. The rough surface of cast iron can harbor objectional dirt, mold and bacteria. Additionally, the mounting surface, or the bottom of the block, is machined for flatness so that dirt and water do not lead to the formation of mold or bacteria.

Interference fit

We know that not every application requires super, high-precision bearings. We stock other industrial parts from quality brands.

No built-in ball bearing support. Good for large orders & low to high torque needs: 1 to 2673 Nm. Bore (ID) sizes: 2 to 240 mm (0.078 to 9.448 in)

Includes built-in ball bearing support. Supports MEDIUM loads & low to medium torque capacity: 53 to 267 Nm. Bore (ID) sizes: 17 to 40 mm (0.669 to 1.57 in)

For high-speed applications, the centrifugal force could cause the inner ring to expand and lift off the shaft which could lead to drastic machine malfunctions and a decrease in bearing life. Increasing the press-fit on the bearing and shaft would help counteract this scenario.

No built-in ball bearing support. Has no RPM limits & Supports high torque needs: 609 to 14,060 Nm. Bore (ID) sizes: 38.09 to 220 mm (1.499 to 8.66 in)

H8 tolerance

The best protection for your bearing. Easy to install with a simple “drop-in” next to your bearing. No added space needed. CF seals offer 100% sealing efficiency against splashing liquids.

However, if the slip fit is too large then micro-fretting between the bearing outer ring (OD) and the housing could occur. In extreme cases, the bearing orbiting geometric center could also result.

Finding the right shaft OD to match the inner ring (or ID) of the bearing and the correct housing ID to match the outer ring (or OD) of the bearing, produces a resultant fit.

Pillow blocks are foot mounted units that are used to provide shaft support when the mounting surface is parallel to the shaft axis. The mounting holes are slotted for ease of mounting adjustment. KMS Plastic Pillow Blocks are made from engineering grade glass filled PBT polyester and are dimensionally interchangeable with conventional cast iron blocks. Polymer Pillow blocks are currently being used in many industries including food processing, bottling and packaging machines, chemical processing, and pool and marine applications. KMS Pillow blocks can be purchased with a variety of KMS insert bearings to best suit your specific application.

Other tolerance recommendations such as shaft and housing concentricity, surface roughness and runout and are located on pages 70-72 of the GMN Bearing catalog.

We recommend using a slip fit on the housing so bearings can move axially for spring preloads or to absorb thermal expansion.

Bearinghousing tolerance

Our GMN Gap Seals are plastic and a great choice for washdown applications, such as food conveyors and food manufacturing facilities

Using our thermal range calculator, you can manipulate the shaft and housing tolerances to automatically find the best tolerance for the resultant fit.

Fit tolerance

Coated or plated cast iron housings can scratch, chip and peel. In fact, the very act of installing them causes the finish to be removed around the edges of the bolt holes beginning the process of corrosion. KMS housings are a solid base glass-filled PBT polymer which requires no coatings for corrosion protection.

Thermal Range Calculator: Calculates the thermal expansion effects due to operating temperatures to find the right shaft and housing tolerances for the application.

Using our free web-based automatic tolerance calculators should give you the tolerance analysis you’ll need for your machined shaft and housing.

On applications where the shaft is rotating, using a press fit will prevent the bearing’s inner ring from rotating, relative to the shaft. If the inner ring rotates separately from the shaft, then micro-fretting and premature bearing failure could occur.

8613869596835

8613869596835