Cost to replace front wheel bearing and hub assembly - 2012 chevy malibu hub bearing

From O-Rings capable of withstanding high pressures to water/dust ingress seals. Learn everything you need to know about choosing the best automotive sealing solutions. You may think automotive sealing solutions belong around the windows and doors of your vehicle, but they are used in various areas inside and outside of the car.

Kaiflex EPDM (Closed cell) – Kaiflex EPDM provides excellent insulation and sealing. Due to its soft closed cell structure and skin finish. It absorbs boot compartment sound effectively whilst offering an excellent NVH solution.

Nitrile rubber (Closed Cell) – Nitrile rubber is a synthetic rubber copolymer of butadiene and acrylonitrile, often referred to as NBR. It’s highly resistant to oils and fuels, and can cope with extreme temperatures ranging from -20 ˚C to + 100˚C.

Depending on its thickness/density, Polyurethane foam is an excellent acoustic and thermal conductive material, due to its cell structure. It can also be supplied in a variety of specialist grades offering conductive, static dissipative and flame-retardant material solutions.

Unlike plastic components, the manufacturing of rubber parts requires a tailored approach to cope with the aesthetic and functional needs, as well as adhering to regulatory requirements. If you fail to consider this, vehicles will not perform at an optimum level and will be more susceptible to the elements.

Superseal foam (Open Cell) – Superseal foams are water-repellent with good water sealing properties. Superseal Foam offers excellent sealing properties, with low water absorption, low air permeability and low compression hardness.

Nowadays, vehicles must consistently handle high engine temperatures and varying weather climates. The growing demand for extended warranties and reduced emissions places a lot of added stress on the sealing process in the manufacturing stage too.

Please feel free to get in touch, to speak with one of our team of experts or simply fill out our online contact form below. We look forward to hearing from you.

Ramsay have the manufacturing capability to manufacture a wide range of custom polyamide foam automotive sealing solution products. Key competencies in the production off:

Dependant on grade, silicone rubber/sponge can provide an ingress protection of IP67. Ensuring high performance sealing for battery compartments.

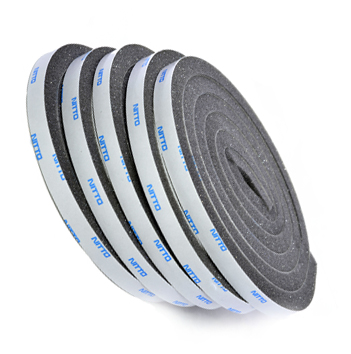

Nitto foam (Semi Closed Cell) – Nitto foams provide the ultimate in automotive sealing solutions. Nitto 1010, 686 and 6801 are EPDM based foams, that have a semi -closed cell structure. Providing a watertight seal between 50 – 80 % compression. Nitto Foams are used in a wide range of interior cabin applications. Predominantly for interior trims, these include dashboard, centre consoles, glove boxes, speakers and grills.

Its material properties ensure a flexibility of solutions. It provides excellent sealing, light weighting and has a significant temperature range – 70°C – +205°C for a number of high-performance battery applications. There is also a wide variety of density’s, between 30 – 100kg

Blend offers oil and petro-chemical resistance as well as offering excellent weatherproofing due to its resistance to ageing, UV, ozone and oxidation. This material provides an excellent seal under compression as well as thermal conductivity and NVH solution

However, the real advantage of superseal is that it offers excellent light weighting whilst providing a good seal when compressed at 80%, it is also more price competitive when compared to other high-performance sealing materials/product.

This material offers superior durability and weather resistance, it also has excellent chemical resistance to acids and alkali’s. Nitto foams offer the best in durability and weather resistance, it is o- zone resistant, fungus free and has an excellent ageing performance ensuring it provides high performance Sealing, NVH, Acoustic and Thermal solutions

Ramsay have the manufacturing capability to manufacture a wide range of custom solid nitrile rubber automotive sealing solution products. Key competencies in the production off:

EPDM sponge (Closed Cell) – Available in a wide range of densities and properties, ensuring optical application performance. EPDM foam sealing is considered one off the best options for weatherstripping vehicle interior cabins and cockpits, due to its good sealing properties against air, dust and water migration. It is also has resistance to ageing, UV, ozone and oxidation.

Ramsay have the manufacturing capability to manufacture a wide range of custom solid/sponge silicone automotive sealing solution products. Key competencies in the production off:

Ramsay have the manufacturing capability to manufacture a wide range of custom EPDM sponge automotive sealing solution products. Key competencies in the production off:

Polyurethane foam (Open cell) – Polyurethane foam is a low-density cost-effective open cell foam providing a variety of automotive sealing solutions. Providing vibration dampening and sealing against air, dust and water migration.

With these material properties, Neoprene EPDM blend can be used for sealing, NVH and anti-rattle. For fuel tanks, tank harnesses, hoses and piping.

Ramsay have the manufacturing capability to manufacture a wide range of custom nitto foam automotive sealing solution products. Key competencies in the production off:

Ramsay have the manufacturing capability to manufacture a wide range of custom polyethylene foam automotive sealing solution products. Key competencies in the production off:

Please note that some materials within retrospective applications can be used across other automotive sealing applications. Please get in-touch to find out more. Within this blog we will cover 5 key automotive sealing solution applications:

R6Z Bearingcross reference

We’re one of the leading automotive sealing manufacturers in the UK. Supplying automotive OEMs and TIERS 1-3 worldwide for the past 25 years. Accredited with IATF16949 and ISO14001 quality standards. All of our materials are registered in accordance with IMDS and are ROSHH/REACH compliant.

Get In Touch Ramsay Rubber & Plastics Limited Vulcan Road, Bilston West Midlands WV14 7HT T +44 (0) 1902 407150 F +44 (0) 1902 407160

Silicone rubber/sponge (Closed Cell) – If you’re searching for a high temperature performance seal in the automotive industry, look no further. As an automotive seal, silicone offers strength, durability and brilliant resistance to heat (-60˚C to 230 ˚C). It also has outstanding weathering properties, UV and chemical resistance.

The smooth surface offers excellent consistency, gauge control and low water absorption and vapour transmission. Materials in this range are extremely durable and have exceptional, Ozone, UV, chemical and weather resistant which provide Acoustic, NVH, Thermal and High-Performance sealing properties.

Neoprene blend (Closed Cell) – Neoprene EPDM Blend offers the best characteristics of both materials in terms of performance and price.

Ramsay have the manufacturing capability to manufacture a wide range of custom superseal foam automotive sealing solution products. Key competencies in the production off:

Ramsay have the manufacturing capability to manufacture a wide range of custom neoprene blend sponge automotive sealing solution products. Key competencies in the production off:

R6Z BearingDimensions

All our high-performance products are manufactured at our site in Wolverhampton based in the West Midlands, utilising a wide-range of die-cutting equipment for medium to high volume adhesive gasket, tape and fabrication production.

Ramsay have the manufacturing capability to manufacture a wide range of custom Kaiflex EPDM automotive sealing solution products. Key competencies in the production off:

Ramsay have the manufacturing capability to manufacture a wide range of custom polyurethane foam automotive sealing solution products. Key competencies in the production off:

Polyurethane foam strips and gaskets can be found on many HVAC components. Including ducts, ducting, evaporator units, hoses, wiring harness and A/C heater controller module.

Polyethylene foam (Closed Cell) – Polyethylene foam is also known as PE and LPDE foam. It is cost effective and rigid, providing excellent HVAC seals under little compression. It is also used for a variety of other automotive sealing solutions. The key advantage of Polyethylene foam is its strength and how lightweight it is comparable to heavier chemically formed foams.

Polyamide foam (Closed Cell) – Polyamide NB foam is a high-performance closed cell, cross-linked nylon foam based on polyamide.

Kaiflex EPDM is also resistant to moisture ingress and chemical inflicted degradation ensuring good sealing properties. It also is exceptionally lightweight, self-extinguishing and has excellent acoustic characteristics.

8613869596835

8613869596835