Custom Length - Grease Fitting Relocation Hose - grease fitting kit

The load capacity can be enhanced even further by not using cages or retainers to hold the cylindrical rollers in place. More rollers can be fitted to carry the load as a result.

Lift the car off the ground with two jack stands. That way, you will find it easier to remove the tire for ball bearing replacements.

Bearings are a critical component of many different types of machinery, and available in a variety of sizes and shapes. They are characterised as a component in a system that supports single motion in either a static or dynamic load.

Bearings' primary function is to prevent direct metal-on-metal contact between two moving parts. Friction, heat buildup and as a result, part wear and tear are all avoided. Sliding motion is replaced by low friction rolling, which saves energy usage. EIBC supplies all types of bearings to various industries and one of the best bearings manufacturers.

Rolling element bearing

While driving to mechanics is more convenient and also time-saving, feel free to replace the bearings at home if you already have all the required tools ready. Write me letters if any type of wheel bearing issues persist

As a load-carrying device, the tapered roller bearing has portions of a cone. These rollers are positioned between the two races, which are hollow cone portions. The races and axes of the rollers would all meet at the same spot if they were stretched.

Block the tires opposite your chosen wheel using a chock. For illustration, if you change the front bearings from the driver’s side, then remember to chock the rear wheels from the passenger’s.

Bearings

My insightful guide, while not offering direct solutions to your budget-saving goal, can still deliver helpful advice regarding the cost and alternative replacement methods. Keep scrolling.

The raceways of spherical roller bearings are angled away from the bearing axis. Instead of straight sides, the rollers have spherical sides that fit onto spherical raceways and accept minor misalignments.

Does the bearing stay flush against the spindle? If so, I suggest removing the spindles – then taking both the bearings and spindles to the nearest repair shop.

Mechanic experts will have specialized tools to help press out those old bearings for you. After the new bearings are pressed in, technicians will re-install the spindles onto the vehicle.

Ball bearing

Automotivebearings

A fluid bearing is a form of bearing that carries the load and eliminates friction by using a pressurised gas or liquid. These bearings are used to replace metallic bearings in applications where there is a high amount of noise and vibration, as well as a short life expectancy.

Locate the rotor faces and place them face down on the ground (the back facing upwards). Then take your new bearing and push its bearing greases into your casing.

Douglas Mercer is an automotive service manager with 12-year experience at Stockton Wheel Service, Douglas excels in addressing intricate tire and wheel concerns as plating wheels, straightening bent wheels, widening stock wheels, and precisely correcting offset and back-spacing…

Rolling bearing

Now that the vehicle is safely secured and lifted, you can proceed to remove the nuts completely. Once done, pull the tires off and place them aside.

In most roller bearings, the length of the rollers is only slightly longer than the diameter. When it comes to needle bearings, the length of the rollers is at least four times the diameter.

Plain bearings are used to transmit rotating, sliding, reciprocating, and oscillatory motions. While the journal glides on the bearing's inner surface, the bearing remains fixed. Material pairs with low coefficients of friction are chosen to assist smooth movement. Copper alloys, for example, come in a variety of shapes and sizes.

Once gathering the required supplies, you should prep the car beforehand to ensure maximum safety. To begin, park the vehicle on an even, level surface.

If you want to play on the safer side and replace every bearing, expect to spend between $800 and $1000 in total. Unless you are already covered by special warranty policies, the overall costs can be quite a blow for most vehicle owners.

There is no point in choosing to do it on your own if these tools have not yet been purchased; buying all of these equipment pieces in one go can be even pricier than having it done by auto mechanics.

Spherical roller bearings are well suited to this condition. They have great load carrying capacity and can handle shaft and housing misalignment. This lowers maintenance costs and extends the life of the equipment.

Because needle bearings have a smaller diameter, they can put more rollers into the same space, increasing the surface area in contact with the races.

Replacing wheel bearings is a piece of cake and can save quite a few bucks, guaranteed you ALREADY have all these tools at home:

Yes. Since wheel bearings and brake rotors are aligned, failed bearings will loosen the brake rotors and cause violent wobbles.

Typesofbearings

SKF bearing

Needle roller bearings are a type of roller bearing with cylindrical rollers that, due to their small diameter, resemble needles.

In addition to radial loads, tapered roller bearings may withstand higher axial loads. The greater axial load this common cone can withstand, the larger the half-angle it has. As a result, they can be used for both thrust and radial loads.

There are several applications for spherical roller bearings. They're employed in situations with big weights, moderate to high speeds, and the possibility of misalignment. Off-road vehicles, pumps, mechanical fans, naval propulsion, wind turbines, and gearboxes are just a few examples of potential applications. Bearings and their types include efficient equipment and bearings material.

The most basic roller bearings are these. Heavy radial loads and high speed are no problem for these bearings. They also have high stiffness, good axial load transmission, reduced friction, and a long service life.

Not to mention, not everyone is familiar with the technical aspects of the vehicle; jumping blindly into it without proper research might end up costing you even more than it should have.

Magnetic bearings keep the shaft in mid-air using the principle of magnetic levitation. Magnetic bearings have negligible wear since they have no physical touch. The highest amount of relative speed it can handle is similarly unrestricted.

To save you hours of research, my team has compiled the average price range of some of the most commonly-asked cars. If yours does not make its way into this list, I suggest consulting your dealer or manufacturer.

The bearing is essentially a sleeve that fits into the bore and is mounted on the shaft. Plain bearings are low-cost, small, and lightweight. They are capable of carrying a lot of weight.

In general, you may expect to invest $190 to $310 for parts associated with the rear bearing replacements. Meanwhile, the labor charges fluctuate from $250 to $400.

bearing数学

A wheel bearing is often stored within the disc brake rotors, meaning you have to pry the dust cap off to expose retaining nuts and cotter pins. A couple of pliers will be your trusted ally in such cases.

The average pricing range can stoop as low as $107-$147 (DIY) to as high as $400-$1000 (mechanic) – depending on whether you prefer DIY procedures or mechanic supports.

Ball bearings have a low friction coefficient when rolling, however, they have a restricted load-carrying capability. Because the contact area between the balls and the races is so small, this is the case. Apart from radial loads, they can support axial loads in both directions.

Put your new bearings into the rotor’s back and apply some grease to the cavity’s interior. Next, install the new seals over the bearing before placing the new retaining nuts on their spindles.

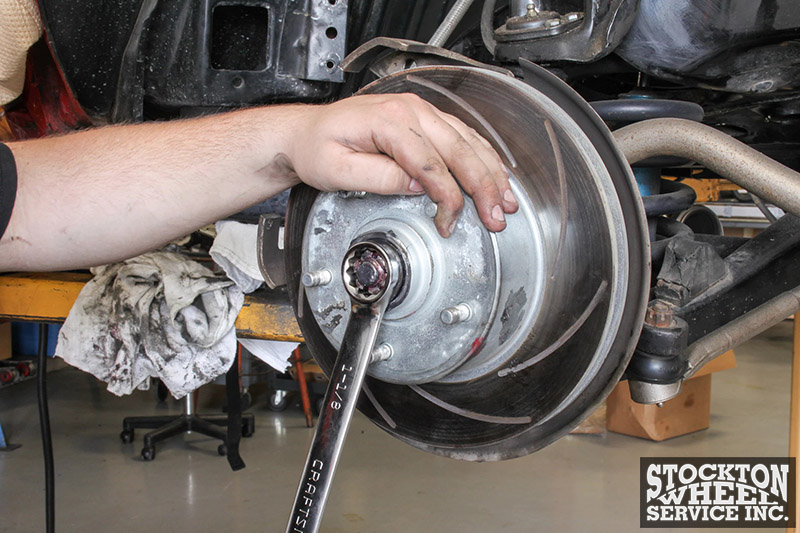

Loosen them with a ratchet (1/2 inches) and proper size sockets. Remember just to loosen them; don’t remove the nuts completely yet.

Use a ratchet to unbolt brackets and brake calipers from the spindles. Once done, remove the calipers with a screwdriver.

Ball bearings are one of the most widely used bearings types. It is made up of a row of rolling balls. They're divided between two metal pieces that are shaped like an annulus. Races are the metal parts that make up this set. The inner race can spin freely while the outer race remains immobile.

Technically, you can, but it’s extremely dangerous. Premature/ uneven tire wear, worn transmission, and even explosions are inevitable.

Hence, I often try to save the cost of wheel bearing by fixing/ swapping only one bearing. It is much cheaper than simultaneous front/rear replacements (refer to the pricing section above) while still delivering impeccable performance.

Regular wheel maintenance schedules should include frequent wheel bearing checks; that has always been a rule of thumb. However, it is the cost to replace wheel bearings that gives people a headache, as they are uncertain whether these upgrades may give huge blows to the financial budgets.

Unfortunately, the front wheel bearing replacement cost is much more expensive than its rear counterparts. The average labor cost runs from $350 to $550, while the pricing for replacement parts is $150 to $300.

8613869596835

8613869596835