CVE-2024-20024 Detail - NVD - 20024

Ultra Heavy Duty Red Grease, 2-Pack of 14 Oz. Tubes| Waterproof Lubricant & High Temp Grease| Wheel Bearing Grease for Semi Truck Accessories

Induction heater tih 030mmanual

Induction heater tih 030mreplacement

The Resource Pack on NGO engagement in the MRM offers a range of tools designed to help civil society organizations and humanitarian partners.

skftih030m/110v

How Are Ball Bearings Made? To begin, heading machines cut wire into short lengths and shape it into spherical shapes between sized dies.

tih030m/230v skf

Amazon.com: Premier Gear PG-WPR6159RM ,Fiat 500L (14-14)500 (12-14)68070266AC68070266AD6807026AE : .

View a map of the businesses, restaurants, and shopping in zip code 33114, Coral Gables, FL. Read reviews and get directions to where you want to go.

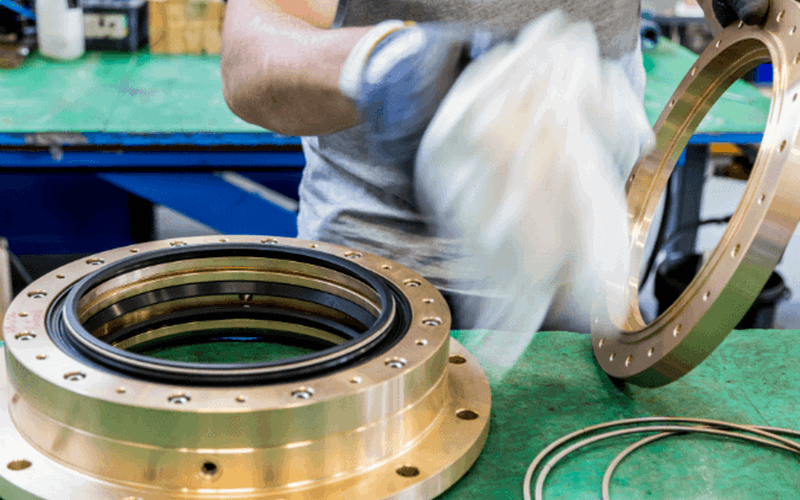

Rotary shaft seals are used to protect installations with a rotating shaft in wet environments. The rotary shaft seals keeps lubricant (oil, grease or water) inside the application and prevents the ingress of water and dirt. Our sealing systems protects thousands ships, pumps and tidal turbines against fluids.

Klüber Lubrication supplies high-performance oils and greases in intelligent packages for automatic lubrication of your machines and components.

Lip seals at rotary shafts work with a small contact area on the liner, which in turn is placed around the shaft. A garter spring ensures a constant force of lip seals on the shaft. The seal works due to a hydrodynamic lubricating film between the lip seal and its counter surface. This area is called the sealing gap and the film thickness, in general, is a few microns. The lubricating film is most stable between two flattened surfaces, therefore over time, the lip seals tip will slowly wear to a small sealing surface.

SKFTIH 030mPrice

Induction heater tih 030mwiring diagram

Induction heater tih 030mmanual pdf

A number of applications that use rotary shaft seals to prevent the leakage of fluids: Propulsion systems at all kind of vessels, like cargo, ferries and superyachts Centrifugal pumps on dredging vessels Process pumps at industrial companies Submerged tidal turbines Pumping stations for water controlYou could use outdated gland packing or mechanical seals for your rotating shaft, but at Lagersmit we rely on rubber lip seals. Rubber lip seals are an essential element in the design of rotary shaft seals at Lagersmit for decades. The two most important functions of rotary shaft seals are: Prevent water, dirt and dust from entering the installation Prevent fluids (usually oil or grease) from leaking out of the installation and ending up in the environment

Our rotating shaft seals are build-up with NBR, FKM or FKM-EAL lip seals, Hastelloy® C4 springs, liners, gaskets, O-rings and housing parts like metal rings. All our sealing solutions for rotating equipment contain two up to five lip seals to ensure a reliable operation. The required number of lip seals depends on the application and environment. Some form a barrier against water ingress and another to prevent lubricant leakage into the environment.

Shaft seal failure and leakage can be caused by several things, but it mostly results in worn-down rubber lip seals. For every shaft seal, there’s a unique service kit to replace the soft wearable parts. Do you need help with the installation? We’ve worldwide available and certified service engineers who can among others assist you with the installation, repair and replacement of shaft seals. Besides that, our engineering manuals can also help you through the process of installation the spare parts on your application.

SKF 7207 BEP Angular Contact Ball Bearing. Reliable quality for your needs. Buy now!!

Veteran Member ... The Axle Nut? Tighten to 200 NM then loosen one half turn. Tighten to 50 NM. Using a torque angle measuring wrench, tighten 60 deg. or 1/6 of a ...

SKFTIH 030mmanual pdf

Equip cars, trucks & SUVs with 2018 Ford Fusion Wheel Bearing/Hub Assembly-Front from AutoZone. Get Yours Today! We have the best products ...

The primary features of cylindrical roller bearings include ring configurations, tolerances, ring standards, and roller retention methods.

8613869596835

8613869596835