CVE-2024-30202 Detail - NVD - 30202

Tapered roller bearings are serviceable, which means they can be removed, cleaned, and repacked with grease to prolong their life. Aside from lasting longer, serviceable bearings are cheaper to replace. However, over a lifetime of service, it may add up to maintenance services/costs. Unfortunately, the majority of vehicle manufacturers do not offer serviceable bearings anymore. Years ago, the Ford F-150 and Toyota Land Cruiser used this style of bearing. The biggest drawback of tapered roller bearings is improper maintenance. Overloaded or improperly pre-loaded bearings wear prematurely. Improper grease packing is another issue when it comes to maintenance.

This site uses cookies to improve your online experience. By continuing to use this site, we will assume that you are agreeing to our use of cookies. For more information about cookies, please visit our cookie policy at Terms and Conditions.

MinebeaMitsumi has improved combustion efficiency and reduced the time lag between the pedal operation and automobile acceleration by adopting high-heat-resistant ball bearings instead of oil-lubricating bearings.

To address these issues, we had to improve the following four main points for the new type of ball bearing unit: Downsizing along with an engine unit downsizing, high durability, high-heat resistance and low torque. In addition, we had to mass produce the bearings so that they would be widely adopted for use in general automobiles and eco-cars. MinebeaMitsumi, which has been continuously improving bearing production technologies since its establishment, has begun to tackle this challenge.

DLTbearings

Worn wheel bearings shouldn't be ignored. The cost of a wheel bearing replacement in front or at the back is a small price to pay for reducing the safety hazards that come with this component wearing out.

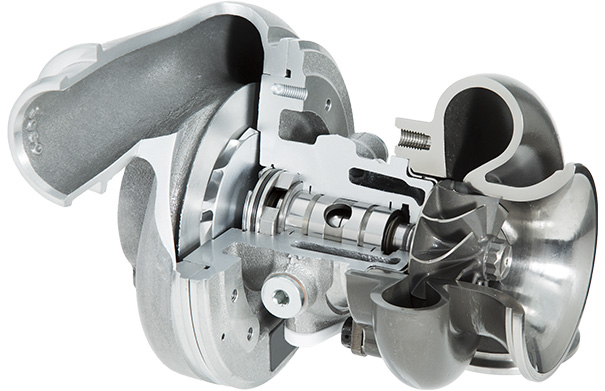

Garrett PerformanceTurbo

If you notice growling or clunking noises, vibrations, abnormal tire wear, or excessive steering wheel play, your car may have one or more worn wheel bearings. Wheel bearings are what make our wheels go round, literally. Despite their simple design and purpose, wheel bearing replacements can be costly. The type of wheel bearing used is entirely dependent on the manufacturer, and you may pay more for a repair on a luxury vehicle. When it comes to replacing bearings, you can do this repair yourself on certain vehicles, while for others, you may need to recruit the help of the pros. In this article, we are going to cover what a wheel bearing is, how it works, the different design types, symptoms of a worn wheel bearing, how to check your car for a worn bearing, and how much it costs to replace a wheel bearing.

Ball bearing wheel bearings are cheaper to manufacture and maintain than their tapered bearing counterparts. Press-in bearings require the use of a hydraulic press to safely remove and replace them. On most vehicles, such as a Honda Civic or Toyota Camry, specifically for front wheel bearing replacements, the steering knuckle will need to be removed. Removing the knuckle will require wheel alignment afterward. Due to the need for a hydraulic press, the need for wheel alignment, and the depth of the repair, most people opt to let the pros handle it. There are options such as removing the steering knuckle at home and taking the assembly into a shop and having them press the old bearing out and the new bearing in. When it comes to press-in bearings, a replacement wheel hub will be the most expensive part. Aftermarket parts such as NAPA offer full assemblies for replacement. This may be the better option, depending on how rusty or worn your vehicle is.

How much is it to fix or replace a wheel bearing? That depends on the make/model of your car as well as the type of bearing. RepairPal estimates a wheel bearing replacement will cost you between $300 and $400. This estimate can be accurate for most vehicles. However, if we look at the pricing for the popular Toyota Tacoma, the price jumps as high as $740. Using a whole knuckle assembly from NAPA or other parts suppliers will cost between $250 and $500, plus labor. Like most repairs, if you do them yourself, you can save some money. However, when it comes to serviceable bearings and press-in bearings, we recommend you let the pros handle the repair, especially if you live in the rust belt.

Marc bearing

As public eco-awareness has been rising and environmental regulations are being strengthened worldwide, automobile manufacturers devote themselves to the realization of new eco-friendly vehicles. One solution to do this is engine downsizing, and a turbocharger, which increases an engine's efficiency and power output while maintaining the performance of conventional engines, has come into the spotlight. MinebeaMitsumi succeeded in developing a next-generation, high-heat-resistant ball bearing unit that directly improves turbocharger performance.

Our (German) subsidiary myonic, which joined the MinebeaMitsumi Group in 2008, is a long-established manufacturer with a history of over 70 years, and it manufactures special ball bearings for aircraft and medical products. PMDM has advanced technologies in fluid and heat analyses cultivated in the hard disk drive (HDD) development. Both companies conducted heat analyses for durability and heat resistance and fluid analyses for ball bearing lubricating oils. Through repeated prototyping and testing, they advanced the development of products that met various requirements. One of the mother plants of MinebeaMitsumi's global production system, the Karuizawa Plant, reiterated prototyping time and again in tandem with the developments in myonic and PMDM to tailor the design of the new type of ball bearing unit so that it could shift the product to mass production. Our main production base, the Bang Pa-in Plant in Thailand, is continuously producing high-heat-resistant bearing units that support the heart of general automobiles and eco-cars in the world, under strict, uncompromising quality control.

Turbochargers, in their heyday in the 1980s, were installed in many racing cars and sports cars to enhance the speed and maximum output of the automobiles. In those days, there was a trade-off relationship between the turbocharger and fuel consumption. Recently, a turbocharger has attracted attention once again as a device for boosting the insufficient output of engines that are downsized to meet environmental restrictions. Thus, its arena of applications has been expanded to general automobiles and eco-cars as well.

Hyundai has just given of its most popular SUVs electric power and a 300-mile range. It's also the brand's first localized EV.

KECBearingspvt ltd

MinebeaMitsumi's global technical development capability and production system were indispensable for the processes from the development to mass production of the new type ball bearing unit. Our German affiliate, myonic, conducted the basic design and development and another German affiliate, PMDM, worked on the fluid and heat analyses. Then, our Karuizawa Plant carried out the prototype/mass production designing and the Bang Pa-in Plant in Thailand took charge of the mass production. As such, the comprehensive strength of MinebeaMitsumi Group, which is expanding business globally, is fully utilized.

These are by far the easiest bearings to work with, as long as you do not live in the rust belt. Issues that arise from bolt-in bearings are bi-metal corrosion and cost. If your vehicle is equipped with an aluminum steering knuckle, expect a fight when removing the steel bearing. This mostly applies to states that suffer from increased levels of vehicle corrosion and rust due to the climate. Since replacement parts come as an assembly, the cost can be higher when compared to a press-in or tapered roller bearing. Vehicles such as the Jeep Wrangler will use these bearings on the front axle and vehicles such as the Toyota RAV4 will use these in the rear.

We highly recommend you avoid driving with a worn wheel bearing. Wheel bearings can become so worn that the hub can fall out of the bearing, causing the wheel to detach from the vehicle. This is a serious scenario that you’ll want to avoid at all costs. Additionally, a worn wheel bearing will reduce the vehicle’s handling and braking abilities. If your wheel bearing is only making noise and does not exhibit any wheel play when inspected, you may have some time before you absolutely need to replace the bearing. However, if the wheel has excessive play due to a worn bearing, you’ll want to get it fixed immediately.

A turbocharger harnesses exhaust gas pressure emitted from the engine cylinder to drive a turbine and a compressor mounted on the same shaft. Air taken in by an automobile is compressed by the compressor and sent to the cylinder, which increases air intake and improves combustion efficiency. The turbine and compressor both play important roles to efficiently send compressed air to the engine. In 2008, MinebeaMitsumi started developing a new type of bearings for a turbine main shaft that directly influences the rotational efficiency.

Wheel bearings provide a mounting point for the wheels and allow the wheels to spin. Wheel bearings are either a tapered rolling bearing design or a ball bearing design. Ball bearing designs are either press-in or bolt-in. Let's take a look at each bearing design in more detail.

Compared to oil-lubricating bearings, the structure of high-heat-resistant ball bearings is more complicated. However, we solved the issues of durability and heat resistance by combining parts made from different materials. For the inner race and outer race, we adopted M50 bearing steel that is also used for the main bearings of aircraft jet engines; and for balls, we adopted lightweight ceramic materials with low calorific value that are suitable for high revolution. We also applied special surface treatment to the retainer to improve the balls' rotation efficiency. Besides downsizing, unitization allowed us to reduce the assembly work in the turbocharger manufacture and improve the stability and balance of the entire part.

It is on the page of High-heat-resistant ball bearing unit for automobile turbochargers

Checking wheel bearings for wear is easy and only requires the vehicle or wheel to be suspended. Follow these steps to check the wheel bearing on your car:

If the wheel bearing is worn, you will feel a popping as you move the wheel. Additional methods for inspecting wheel bearings include using chassis ears, a stethoscope, and a dial indicator (to measure the exact amount of wear).

Take a closer look at how the Grand Cherokee differentiates itself from the currently absent yet time-tested Cherokee SUV.

Garrett ball bearingturbo

The bearing for turbine main shafts is used for the turbine driven by ultrahigh-temperature exhaust gases exceeding 800°C as the power source, and it must withstand ultrahigh speed of over 200,000 revolutions while continuously immersed in oil. For this reason, many turbochargers for general automobiles used oil-lubricating bearings that are highly resistant to harsh environments. However, since the friction resistance of oil-lubricating bearings increases at the time of acceleration and deceleration due to its structure, the speed following capability is inferior to that of ball bearings (particularly when an engine starts at the low temperature). This generates a time lag between the increase in intake air pressure and the step-in operation of the accelerator pedal. Consequently, the driver feels the acceleration to be slow, and depresses the accelerator pedal more than necessary, thereby resulting in poor fuel economy. In actual city driving, since acceleration and deceleration are frequently repeated, a series of those steps tend to affect practical fuel economy.

A turbocharger is a device to increase an engine's power output with a smaller engine capacity by improving the engine's combustion efficiency through the recycling of exhaust gases that are normally discarded.

Wheel bearings can exhibit growling/howling noises and show no signs of play or wear, other than excessive noise. To diagnose these, you’ll need to drive the vehicle at various speeds in turns. A left front-wheel bearing that is worn may only make noise during left turns or right turns.

Since its establishment as Japan's first specialized manufacturer of miniature ball bearings in 1951, MinebeaMitsumi has been leading the development and production of the world's miniature ball bearings and conducting R&D constantly to meet the needs of the age. We have realized the mass production of a high-performance product, i.e., the high-heat-resistant ball bearing unit introduced this time, by applying MinebeaMitsumi's technologies cultivated over the years. Our engineers in Germany, Japan and Thailand cooperated to achieve the same goal through the development and production of a single product, and they have created an organic linkage in MinebeaMitsumi Group. No matter how complicated it may be, MinebeaMitsumi has the technologies to create any type of ball bearings only with drawings. As a leading manufacturer of miniature ball bearings, we are proud that there is no miniature ball bearing that we cannot create.

8613869596835

8613869596835