Deep Groove 60/28 Ball Bearings 28mm X 52mm X 12mm - 60 - 28

Replacing a car wheel bearing typically involves several steps and requires some mechanical knowledge and tools. Here's a general overview of the process:

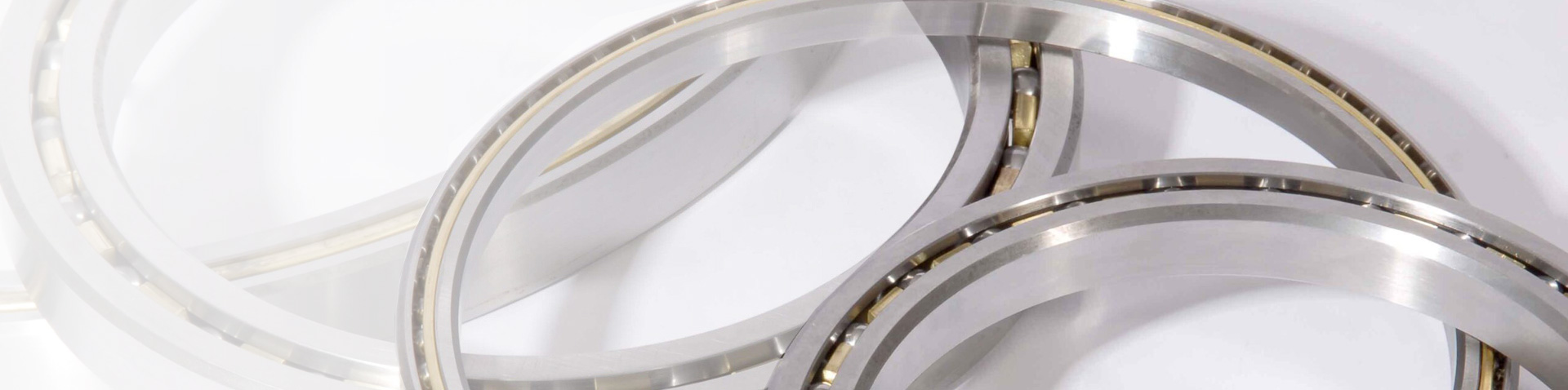

The B-Type thin section bearings are a back-to-back pair matched set using two A-Type angular contact bearings that are arranged back-to-back with load lines diverging from the bearing axis. Because the A-Type alone can only take the axial (thrust) load in one direction, they are typically used in a pair matched arrangement. When they are pair matched, they can accommodate axial loading in both directions. One of the two types of arrangements is a back-to-back matched set, also called a duplex pair.

A car wheel bearing is a crucial component of a vehicle's wheel assembly that enables smooth and efficient rotation of the wheel while driving.

Thin section bearingsCatalog

Wear and tear: Over time, bearings can wear out due to constant use and exposure to various road conditions. When they become worn, the metal balls or rollers inside may lose their smoothness, causing friction and generating noise.

NSK Thin-Sectionbearings

A seal is typically made of rubber or other materials. Sealed bearings are more suitable for applications where the primary concern is preventing contaminates such as dust, dirt, and moisture from entering the bearing.

Thin section bearingsprice

It is highly recommended to consult your vehicle's repair manual, call a mobile mechanic or seek professional assistance from a local garage.

The bearing is typically mounted within a hub assembly or wheel hub, which connects the wheel to the vehicle's suspension system.

Born to thrive under the most rigorous conditions, our Silverthin bearings excel in the face of daunting challenges, consistently outperforming industry expectations. Earning their stripes in aerospace, medical systems, robotics, astronomy instrumentation, and machine tools, they stand as testament to engineering marvels in motion. The cascading benefits of our design ethos extend beyond function, culminating in substantial savings – whether it’s in space utilization, weight considerations, or cost-effective solutions – all realized without compromise.

When specifying this type of bearing for use with axial or moment loads combined with radial loads application speed (rpm) is a real concern. Please contact Silverthin engineering for information on combined load and limiting speeds.

Purchase Order Terms and Conditions • Quality Requirements • Return Materials Authorization Sales Order Terms and Conditions • Privacy Policy • Legal Notices

Thin sectionball bearing

It's crucial to note that these are general guidelines, and the specific steps and procedures can vary depending on your vehicle's make and model.

A common issue for most car owners relates to the car wheel bearings. But what are they? Why are they important? And can you replace them yourself?

Thin section bearingsfor sale

A shield is typically made of metal. Shielded bearings are more suitable for applications where the primary concern is larger debris or particles rather than fine contaminants.

As a rough estimate, the price for a single wheel bearing can range from £150 to £250. However, this is only an approximate range, and the actual cost can be higher or lower depending on the factors mentioned above.

Please contact Silverthin for radial bearing use with combined radial loads with axial or moment loading and for limiting speeds and separator selection.

The X-Type, or 4-point contact, ball bearing is ideal for moment loading. X-Type bearings are designed with gothic arch raceways creating 4 contact points between the balls and the raceways. This design is excellent for moment loading and reversing axial loading. The X-Type bearing can be used for other light loading conditions, but is not recommended in place of the C- or A-Type bearing for pure radial loads.

Thin section bearingssizes

Common signs of a failing wheel bearing include unusual noises such as grinding or humming coming from the wheel, vibration, uneven tyre wear, and excessive play or looseness in the wheel.

Our diverse range of Silverthin bearings extends across materials, cage configurations, cross-sectional profiles, internal clearances, and preload options. Lubricants, corrosion-resistant options, contact angles, and tolerance classes are equally at your disposal, accentuating the customizable approach of Silverthin.

A shield is typically made of metal. Shielded bearings are more suitable for applications where the primary concern is larger debris or particles rather than fine contaminants.

If you suspect a faulty wheel bearing, it is essential to have it inspected and repaired by a qualified mechanic. Ignoring a worn or damaged wheel bearing can result in further damage to the wheel assembly and compromise the safety and performance of your vehicle. Alternatively, take your vehicle to your local garage to get the problem resolved.

Two A-Type bearings are often used as a duplex pairs. Multiple configurations are available for duplex and superduplex. See Type B, Type F, Type T, Type M and Type W below to reference. Contact Silverthin engineering for additional standard and custom configuration options for angular contact Type A thin section bearings.

A seal is typically made of rubber or other materials. Sealed bearings are more suitable for applications where the primary concern is preventing contaminates such as dust, dirt, and moisture from entering the bearing.

Mechatronics is a privately held marketing, distribution, and manufacturing company that was founded in 1979. Today, the corporation comprises four operating groups that serve diverse markets.

Improper installation: If a wheel bearing is not installed correctly during maintenance or repair, it can lead to premature wear and noise. Improper installation can result in misalignment or insufficient torque, causing the bearing to wear unevenly.

In applications with axial loads in one direction the A-Type, angular contact ball bearing should be used. This bearing also works well in radial or combined radial-thrust applications. The A-Type bearing should never be used alone to support moment loads or reversing axial loading.

Contamination: Dirt, debris, or water can enter the wheel bearing and cause contamination. This can accelerate wear and create noise as the foreign particles interfere with the smooth rotation of the bearing.

RBCthin section bearings

The Sealed or Shielded C-Type contact ball bearing has radial contact, meaning it primarily supports loads that acts perpendicular to the axis of rotation. Additionally, they are equipped with either seals or shields to provide some level of protection against contaminants, while allowing for smooth rotation.

Crafted with precision and ingenuity, our Silverthin bearings redefine excellence in engineering. Deviating from the conventional, these extraordinary components embrace a spectrum of benefits that transform design possibilities. With a fundamental commitment to weight reduction, space optimization, and friction minimization, Silverthin bearings establish new benchmarks in efficiency. Their formidable versatility is matched only by their impeccable accuracy in operation.

It's advisable to check with local automotive parts suppliers or contact a trusted local garage to get more accurate pricing information specific to your vehicle.

If you can hear a strange noise coming from your wheels – it could be an issue with your wheel bearings. It could also indicate a serious issue.

It’s worth noting that the specific location and design of bearings may vary slightly between different vehicle models and manufacturers. It is recommended to consult the vehicle’s manual or visit a trusted local garage for an accurate assessment and information regarding your specific car’s wheel bearing location – and what is needed to fix it.

Excessive load or impact: Intense driving conditions, such as carrying heavy loads or encountering potholes and impacts, can put additional stress on the wheel bearing. This can lead to damage, wear, and ultimately noise.

In most vehicles, the wheel bearing is a sealed unit that is pressed into the hub assembly. It is positioned between the inner and outer bearing races, which are the metal rings that contain the steel balls or rollers.

Keep in mind that if you're replacing a wheel bearing, it's usually recommended to replace both bearings on the same axle simultaneously, even if only one is showing signs of wear or damage.

Keeping on top of regular car maintenance and getting your car serviced can help avoid this issue affecting your vehicle.

Depending on the vehicle’s design, there may be one or two wheel bearings per wheel. In a front-wheel-drive vehicle, each front wheel usually has a wheel bearing assembly, while rear-wheel-drive vehicles may have wheel bearings in the front and rear wheels.

The T-Type thin section bearings are a tandem mounted pair matched set using two A-Type angular contact bearings that can accept a very high axial load in one direction only. This is different from the back-to-back and face-to-face pair matched bearings, that can accommodate axial loading in both directions.

If a wheel bearing is damaged or worn, it should be replaced promptly to ensure safe operation of the vehicle and prevent further damage to other components.

The car wheel bearings are located within the wheel hub assembly. This is the part that connects the wheel to the vehicle's suspension system.

SKFthin section bearings

The cost of a new car wheel bearing can vary depending on several factors, including the make and model of your vehicle, the location of the bearing, and whether you purchase an original equipment manufacturer part.

When specifying this type of bearing for use with axial or moment loads combined with radial loads application speed (rpm) is a real concern. Please contact Silverthin engineering for information on combined load and limiting speeds.

The C-Type, radial contact ball bearing is designed with deep ball grooves to withstand high loads. Although this bearing is used primarily in applications with radial loads, it can withstand moderate axial loads, reversing axial loads, and moment loads.

Lack of lubrication: Adequate lubrication is crucial for the smooth operation of a wheel bearing. If the bearing is not properly lubricated or the lubricant has deteriorated over time, it can result in increased friction and noise.

The F-Type thin section bearings are a face-to-face pair matched set using two A-Type angular contact bearings that are arranged face-to-face with the load lines converging towards the bearing axis. Because the A-Type alone can only take the axial (thrust) load in one direction, they are typically used in a pair matched arrangement. When they are pair matched, they can accommodate axial loading in both directions. One of these two types of arrangements is a face-to-face matched set, also called a duplex pair.

The Sealed or Shielded X-Type contact ball bearing or 4-point contact ball bearing is ideal for moment loading. X-Type bearings are designed with gothic arch raceways creating 4 contact points between the balls and the raceways. Additionally, they are equipped with either seals or shields to provide some level of protection against contaminants, while allowing for smooth rotation. This design is excellent for moment loading and reversing axial loading. The X-Type bearing can be used for other light loading conditions, but is not recommended in place of the C- or A-Type bearing for pure radial loads.

8613869596835

8613869596835