Deep Groove 6204 Ball Bearings 20mm X 47mm X 14mm - bearing 6204

Static load vs dynamic loadbearing

Reduce the wear on your engine with new delayed engine shutdown, which can be scheduled to activate automatically by the operator. The intelligent function turns off the machine when the turbo charger has cooled down to the appropriate temperature, reducing component wear.

Minimize downtime and increase component life with easier access to the Boom Suspension System accumulators – now placed on the outside of the front frame – and P-brake, which is now external.

Static loadanddynamic loadcalculation

Customize your machine and ensure precise control of hydraulic functions, with the choice of single or multi levers. To get the most out of each operation, select from three hydraulic modes, according to your preferred responsiveness. To reduce operator fatigue and improve productivity, Comfort Drive Control gives you the opportunity to steer the machine from a small lever.

The Collision Mitigation System has been developed to support the safe operation of Volvo Wheel Loaders. The optional system assists operators while working in reverse by automatically applying the brakes when the machine approaches an obstacle, helping to reduce the risk or consequences of collisions and enhance jobsite safety.

Short-term age, in the sense of the least possible number of hours that should elapse between molding and subsequent evaluation, is also a significant factor affecting load deflection. Depending upon the nature of each particular product, this minimum period will vary from 24 hours to 168 hours.

Often, when making use of rubber, stiffness variation is not critical to the rubber product’s function, and in such cases, the Shore A durometer hardness specification is sufficient. But rubber is frequently used as an engineering material in applications like resilient mountings, vibration isolators, dampers, impact pads, and similar. In instances where static or dynamic stiffness characteristics become critical to a product’s function, appropriate test specifications must be instituted.

Static vs dynamic loadformula

To enhance visibility, the L260H has new rear-view mirrors and can be equipped with a rear-view camera. Optimized by the radar detect system, which works with the camera to give a visual and audible alert to the operator of unseen on-coming objects. Orange handrails and steps have been placed on the machine, intended to stand out to the operators and maintenance staff.

The aging of rubber compounds over time is a complex process. The normal net effect of aging is an increase in modulus or stiffness. The magnitude of this change is dependent upon the specific material involved, as well as the environmental conditions to which it was subjected.

Get the most out of your L260H with our range of purpose-built attachments, perfect for applications such as quarrying, aggregates, mining and heavy infrastructure. Form one solid and reliable unit with attachments that are ideally matched by size and design to your machine’s parameters – including link-arm geometry, and breakout and lifting forces.

For strength in demanding applications, Volvo’s proven Z-bar linkage provides high breakout force. The robust lifting arm enables fully loaded buckets to be elevated to maximum height and fast hydraulic speeds offer quick cycle times. For long lasting performance, the lifting arm has double sealing on each of the pins.

The following details must be defined by the product drawing, or by the referenced specification, to ensure both a relevant and consistent evaluation of product performance:

Difference betweenstatic loadanddynamic loadPDF

Primed for productivity, the innovative L260H combines the latest Volvo technology with power and upgraded components to help you increase your payload. To achieve ultimate performance, select from a range of tailor made Volvo attachments.

Unlock the full potential of your machine and take on demanding applications, with a range of purpose built attachments. Volvo can custom build attachments to your specific requirements, increasing your productivity.

Extend the life of your bucket with a choice of reinforcement options. Bolt-on edges protect the bottom edge of the bucket, while segments protect the cutting edge of the bucket, increasing durability.

Maintain productivity with our range of Genuine Volvo Parts – all backed by Volvo warranty – with 24-hour parts delivery guarantee. Maximize machine uptime and reduce repair costs with ActiveCare Direct. The intelligent service provides around the clock machine monitoring, as well as customer reports, to help take predictive and preventative maintenance actions.

Make overloading, underloading, reweighing and waiting times a thing of the past with On-Board Weighing, providing real-time insight into the bucket’s load. What’s more, with the new Simple Mode, it has never been easier to start reaping the benefits of On-Board Weighing.

Built with the customer, for the customer, the L260H boasts a range of features to enhance your operating experience. For increased productivity, the Volvo cab can be customized to your preference and additional cameras offer greater visibility.

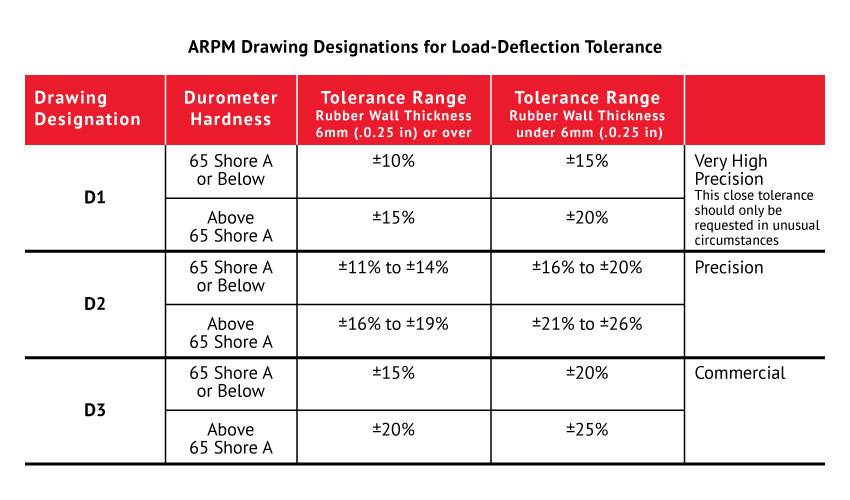

When applicable, the design engineer must specify method of test, spring rate, and load deflection along with associated tolerances. If damping characteristics are required as a part of a dynamic specification, commercial tolerances would be ±25% on parts up through 65 durometer hardness (SHORE A) and ±30% for parts above 65 durometer hardness (SHORE A).

Static vs dynamic loadreddit

Experience up to 5% greater productivity with the new 7.3 m³ (9.5 yd³) Volvo Rehandling bucket. The redesigned bucket is easier to fill and minimizes spillage, thanks to new convex sides and an improved spill guard. To prevent spillage and absorb shocks, opt for the Boom Suspension System, which automatically engages, depending on gear or speed selection.

For improved cycle times and greater fuel efficiency, customize the lock-up engagement of your machine with new generation OptiShift. The improved technology integrates the Reverse By Braking (RBB) function – patented by Volvo – and the new torque converter with lock-up, creating a direct drive between the engine and transmission, reducing fuel consumption.

Static vs dynamic loadcalculator

Temperature affects spring rate. For a rubber product not under continuous tension: the higher the temperature, the lower the spring rate, and the lower the temperature, the higher the spring rate.

Designed with durability in mind, the L260H is built with a Lifetime Frame and Structure Warranty, including the front frame, rear frame, articulation joint and loader arm. The hydraulically-driven cooling fan regulates component temperature and automatically reverses, permitting self-cleaning of the cooling units.

Engineered for efficiency and productivity, the L260H is fitted with a powerful Tier 4 final engine, delivering 6% more power and 5% more torque than the L250H.

Where rubber is used as a vibration isolator, such applications are dependent upon the behavior of the rubber when subjected to these dynamic operating conditions.

For ultimate performance, the L260H has been upgraded with the new HTL310 transmission, which works in harmony with the powerful engine and axels. The new converter delivers increased torque output, resulting in better performance. For faster acceleration and smooth operation, the steps between gears have been reduced.

Static loadanddynamic loadexamples

To enhance visibility, the L260H has new rear-view mirrors and can be equipped with a rear-view camera. Optimized by the radar detect system, which works with the camera to give a visual and audible alert to the operator of unseen on-coming objects. Orange handrails and steps have been placed on the machine, intended to stand out to the operators and maintenance staff.

Offering strength in demanding applications, the L260H is built to last. Maintain the life of your machine with simple serviceability and proactive dealer support, as well as flexible maintenance and repair plans.

When a static load-deflection specification is established for a product—in addition to a hardness requirement—the load-deflection specification shall supersede the hardness requirement. Additionally, the specification should be agreed upon by both the customer and the rubber manufacturer, and then be clearly stated on the product drawing. A static test is only “static” in that the load application comes to rest before the measurement is taken; or that the rate of deflection does not normally exceed 0.8mm/s (2 in/min). Such a test usually places the rubber in shear or compression.

Static loadexamples

Optimize your load cycles with Load Assist, powered by Volvo Co-Pilot – the 12” in-cab display. Gain access to a set of smart apps and boost the efficiency of your operation. When installed, the rear-view camera and radar detect system are now integrated into the Volvo Co-Pilot.

Get accurate machine positioning with Map, a clever app that allows operators to monitor on-site traffic in real-time. Not only does this give operators an improved orientation of the site they are working on, but it allows them to proactively adjust their driving behavior according to traffic conditions.

Operator Coaching helps to ensure operators are using their Volvo machine to its full potential. The intuitive app provides real-time guidance to operators, helping them understand how their actions influence machine productivity and efficiency, as well as identify areas for improvement or changes in their technique.

Rubber and urethane provide greater deflection for applied forces than do rigid materials such as metals or ceramics. Most uses of rubber are based upon this characteristic. Urethane may be selected for the same attribute, in addition to its excellent impact strength and abrasion resistance.

When dynamic stiffness or spring rate is specified, and is also determined to be critical to the performance of the rubber product, the complete test conditions and methods of measurement must be clarified between customer and rubber manufacturer.

With the tire pressure monitoring app, you can check the condition of your tires from the comfort of the cab. Providing real-time information on tire pressure and temperature, the system saves time during machine inspections and can prolong tire lifetime.

The load-deflection characteristics of a rubber product are affected by its work history. For new parts, or parts that have been in a static state for a period of time, their initial loading cycles indicate a stiffer load-deflection characteristic than noted in subsequent cycles. In static testing, this effect becomes stabilized, and so the load-deflection characteristics typically become repeatable after two to four conditioning cycles. In dynamic testing, the conditioning period is usually designated as the amount of time necessary for obtaining reproducible results.

Save on machine wear and increase fuel efficiency with the eco pedal. Uniquely designed by Volvo, the eco pedal encourages economical operation, by applying a mechanical push-back force in response to excess use of the accelerator.

Do more with less fuel, thanks to a powerful engine and new generation hydraulics, which save hydraulic pump power for other functions, by reducing fluid flow when lowering and dumping. Coupled with the new dry P-Brake, which eliminates drag losses caused by the internal wet multi-disk brake.

Rubber is stiffer dynamically than when in a static mode; and since the static-to-dynamic stiffness ratio varies with individual compounds, it may be advisable to specify the dynamic characteristics of the rubber for usages of this manner.

Identify any inefficiency with Fuel Report, designed to help you reduce the industry’s number one operational cost factor. With detailed machine data, Fuel Report supports in taking corrective actions to reverse machine issues and improve fuel efficiency.

Achieve shorter cycle times with next generation load sensing hydraulics, designed to enhance the responsiveness of attachments and improve the lifting and lowering speed of the boom.

8613869596835

8613869596835