Delivering trust and impact for global social responsibility ... - 24000

Start by monitoring the bearing's friction level with ultrasound as new grease is applied, one shot at a time (and slowly, of course). [source]

Where to buygrease for ball bearings

Although they are similar, these two types of oils offer unique properties and cannot be interchangeable. Mineral oils are more common than synthetic oils.

Oil lubricant is generally used for high speed or high-temperature applications that require heat transfer away from working bearing surfaces. The oils consist of either natural mineral oil (with additives that prevent oxidation and rust) or synthetic oil.

As lubrication experts trusted by major manufacturers, we know finding the correct grease for your bearing application can be a struggle. We can take some of those burdens with our 30+ years of experience and knowledge and be your "go-to" for lubricant optimization.

With this type of lubrication, the bearings are spattered with oil by moving parts that are regularly dipped in the lube oil. This method is preferred when rotation is not fast enough to churn up the oil.

Rule of thumb equation - This method is one of the more complex ones to determine fill quality, and it's also worth noting that this method is exactly that, a 'rule of thumb' with limited accuracy.

Ballbearing oil

Simply put, using an ultrasound device that doesn't give measurement feedback to listen to a bearing sounds like a great idea in theory, but it's just going to hurt you in the long run.

This method works best for applications that operate with low speed or have available lubricant cavities because they don't require an extremely accurate measurement of the free space.

High Speed Bearing Oil

These charts are great reference tools, however, it's essential to keep in mind that the free space information presented in them is generalized.

Over-lubrication can increase internal friction, which leads to extra heat generation while under-lubrication can lead to wear or lubrication starvation due to contact surfaces not having enough lubrication.

The proper fill quantity of a grease lubricated bearing is frequently specified as a percentage of the bearing's free space, therefore, it's important to determine the free space correctly.

Buy (R)-2-Methyl-1,4-butanediol (CAS 22644-28-6), a specialty product for proteomics research, from Santa Cruz. Molecular Formula: C5H12O2, MW: 104.15.

As a general rule, bearings run the coolest and with the least amount of friction when a minimum amount of the lightest-bodied lubricant that will keep the bearing surfaces apart is used, according to knowyourparts.com.

Bearing oil vsgrease

Bearing lubrication, although a simple concept, can have its challenges and requires following specific guidelines to ensure it's done correctly.

My name is Dean Payne and I am the Sales Manager at BDS. I have been with BDS for 19 years and started when I was 18 years old in the warehouse. I have learned a little bit about bearings over the years and would consider myself a career-bearing guy at this point. I enjoy the challenges and the constant changing of nomenclature the bearing industry has to offer, you learn something new every single day.

While it's not a difficult process, it does require following specific guidelines that aren't done properly. As a result, many plants or facilities have inadequate lubrication programs and bearing failures.

MEDTRONIC XOMED 400300 Merocel Instrument Wipe 92x76mm (20/Box) ... All Items listed are on inventory. When the item is expired must be used for educational, ...

Bestgrease for bearings

Bestgrease for ball bearings

You can monitor, measure, and trend friction levels with ultrasound instead of re-lubricating a bearing on a schedule so you can know exactly when it's the right time to grease, according to Maint World.

Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction.

In a force fed lubrication system, an oil pump pressurizes the oil, which is then directed to the rotating component. Examples of systems that use this method include boiler feed pumps, compressors, gearboxes, and turbine generators.

Doing so will ensure smooth-sailing for your facility and prevent unplanned downtime, lost revenue, and decreased operating efficiency due to bearing failure that stemmed from lubrication issues.

If you're looking for lubrication services to help you meet your customers' specifications, Bearing and Drive Systems has over 200 types of grease and oil in stock from all of the top companies to meet your needs. Get a quote today and we can take some of your burdens with our 30+ years of experience and knowledge and be your "go-to" for lubricant optimization.

As we've discussed already, too much grease builds up and eventually causes increased friction and pressure, and that causes excess heat. Too little of grease has the same life-shortening effect on bearings too.

An easy fix here is to use an ultrasound with a digital decibel metering. You can use a device that provides multiple condition indicators– if you have that available to you.

In most cases, the best place to start selecting the right lubricant is to follow the bearing manufacturer's recommendations.

It's no secret that proper lubrication has the largest impact on bearing life. In fact, it's an industry-wide understanding that at least 80% of bearing failures are related to lubrication and contamination issues. [source]

Grease adheres to bearing surfaces better than oil, has a longer lifespan, and is less likely to run off or be ejected from rotating parts. [source]

Proper fill quantity ensures that all contact surfaces have a suitable lubricating film. This step is crucial because, as we've discussed already, over- and under-lubrication are both detrimental to bearing operating life.

According to the National Lubricating Grease Institute (NLGI), the grease's consistency class indicates how the grease will flow and disperse within the bearing.

It's common for bearing companies to provide pre-coated products with an oil film or anti-corrosion coating. As long as the coating has both a micro-thickness and is compatible with your chosen lubricant, then pre-cleaning might not be needed, according to Guide to Proper Bearing Lubrication Procedures by Klüber Lubrication.

The manufacturer usually applies the oil with special equipment, however the amount added to the bearing is not specified.

Grease is needed in bearings for one reason— to prevent and reduce friction. If the lubricant is doing its job well, you don't need continue changing it or adding more.

It also can be pre-lubricated, which eliminates the need for an external lubrication system and means less maintenance in the future.

While some bearing applications use oil as a lubricant, grease is the lubricant of choice for 80 to 90 percent of bearings.

Many different methods can be used to apply oils and greases, however, there are four standard methods that are typically used to supply lubrication to bearings.

Lubrication mistakes can be far-reaching. Common side effects of incorrect lubrication include overheating or excessive wear, which can lead to bearing failure. And that can lead to unexpected downtime and lost revenue at your facility.

When operating equipment at heavy loads and high speeds, you need to protect the equipment from high temperatures as a result of fiction by supplying a high flow of oil.

Grease lubricants are made up of three components: additives (usually rust inhibitors), a base oil, and a thickener. When you are selecting a grease lubricant, it's important to note that the viscosity of the base oil (referred to as "base oil viscosity") determines how the lubricating film develops.

Loss of lubricant - if a bearing isn't re-greased with proper intervals and the proper amount of grease, loss of lubricant and lubrication can result and contribute to equipment failure.

In this first step, you need to remove any existing oils, anti-corrosion coatings and greases. This part is essential because the operating life and reliability become more critical and help eliminate any potential incompatibilities.

Simply put, this method (often called a gravity feed system) "consists of a loosely covered cup or manifold of oil placed above the bearing that meters out oil at a set interval," according to Tech Transfer.

While lubricating a bearing once a week or every month seems like a practical task to do, it's actually causing your bearings more harm than good.

Greases do not leak out as easily as oils, however, since they are so viscous, they cannot be pumped continuously through equipment to remove heat.

,,+ b2b

Since greases are semi-solid lubricants, they are often used when the lubricant needs to stay in one place or stick to a part, and are ideal since they are less maintenance.

by Y Meged · 2020 · Cited by 3 — Three types of lubricants and their water contents at the relative humidity of 20% at 30 C. and hydraulic modes [3]. The mechanical mode, based ...

Published reference charts - Manufacturers have also developed generalized bearing free space charts, which help you calculate a specific bearing's free based on the inner diameter and design configuration.

In systems where low loads and low-to-moderate speeds are expected, bearings of this type require small quantities of oil that are applied at regular intervals.

You'll want to listen to the bearing and try to measure the drop in friction as the grease begins to flow into the bearing. Keep note as the decibel level approaches a minimum value and stabilizes, add single shots, and if the decibel level begins to increase even slightly, you can stop because your job is done.

If you want to learn more about what a bearing failure is and the different types you can come across in your facility, download our guide "What Causes Bearing Failures and Preventative Measures You Need to Know."

These bearings can easily be replaced, are less expensive to buy, and generally cost around $6-20.00 per unit, and $80-100.00 to service.

As we've touched on already, bearing lubrication plays a critical role in the lifespan and performance of bearings because it helps separate parts moving parts in order to minimize friction and prevent wear.

These include "the type of machine, bearing type, size, temperature, load conditions, speed range, operating conditions (such as vibration and horizontal/vertical orientation of the shaft) and external environment," according to Efficient Plant Magazine.

In addition to providing that separation, it also dissipates frictional heat (which prevents overheating and deterioration of the lubricant) and protects against other known issues like corrosion, moisture, and other contaminants.

It's important to remember that regardless of which type of lubricant you chose, it will naturally lose its lubricating properties over time and if not maintained properly with the help of an experienced lubrication service, will eventually lead to bearing failure.

The oil's viscosity correlates to the film thickness it can create, which is crucial to the separation of the rolling and sliding parts of a bearing.

Published engineering data - Manufacturers may have done the work for you by determining the free space for a number of their "catalog bearings." This means a simple email or phone call to the manufacturer's engineering department can get you the answers you need.

2011315 — Here's the definition, right out of the NRA Firearms Sourcebook. It is ...the minor interior diameter of a barrel that is the diameter of a ...

It requires selecting the right lubricant for each application (like we discussed above), applying it correctly, and sticking to a lubrication schedule that meets the equipment's needs.

Grease incompatibility - It's crucial to stay with the same grease (or a compatible substitute) for the entire life of a bearing. Not all greases are compatible with each other.

There are clear benefits to optimizing your bearing lubrication and avoiding these three mistakes. Doing so will extend the life of your bearings, cut down on grease consumption, and decrease time spent re-lubricating when it's not necessary.

Two set screws 120° apart in inner ring lock unit securely to shaft. Features one-piece cast iron housing, solid base, wide inner ring bearing, dual heavy-duty ...

This type of lubrication was applied by hand in the past, but it actually poses risks like over- or under-lubricating. Drip feed lubrication systems are more commonly used for these applications to supply the correct amount of oil at the right intervals.

How to usegrease for ball bearings

According to Guide to Proper Bearing Lubrication Procedures by Klüber Lubrication if done correctly, run-in procedure will:

Grease is typically applied with special equipment that deposits the grease between the balls, which forces it inside and around the ball or roller raceway interface. Unlike oil, grease is normally denoted as a percentage (e.g. 30% fill), which represents the actual grease volume compared to the free internal space inside the bearing. [source]

Proper run-in procedure is crucial to the bearing and lubricant's performance in the application where high speeds, fill quantities, and specific pre-loads are critical.

Now that we've gone over applying best practices for bearing lubrication, let's find out the three lubrication mistakes you could be making that are ruining your bearings.

The proper application procedure is as important as selecting the right lubricant. The most important areas in applying a lubricant include bearing cleaning, lubricant fill quality, and bearing run-in.

... rollers, straight rollers, v-groove rollers, and more. We can produce polyurethane rollers using a variety of hub materials, both bored or with bearings.

2006914 — If your question is how long should they last, they should last the life of the car, well over 100K for Volvos. Heavy loads, exceeding GVW ...

Grease degradation - Common types of grease degradation include oil separation from the grease base, chemical breakdown due to excessive heat, and grease hardening.

Over time, lubricant in a bearing will naturally lose its lubricating properties, but it's still crucial to pay careful attention to the quality of the original lubricant and to take the above steps we've outlined to preserve the bearing, and it's intended lifespan.

Though often viewed as a messy, auxiliary process that has been followed since the Industrial Era to some, bearing lubrication is actually a crucial technology that can make or break your manufacturing processes at your facility.

Here are three common lubrication mistakes you could be making and how to avoid them (or fix them) so you can be confident in your bearing's health.

60/28 ... Single Row Deep Groove Ball Bearings are widely recognized as the predominant type of rolling bearing, featuring inner and outer ring raceway grooves ...

Because we take extending the life of your bearings enormously, we put together this in-depth guide to discuss the different types of lubricants, the best methods for bearing lubrication, proper procedure for applications, and mistakes you might be making to ensure the long service life of your bearings.

Excess lubrication - This occurs when excess grease causes the temperature to increase excessively in a bearing, which normally only happens in open face bearings.

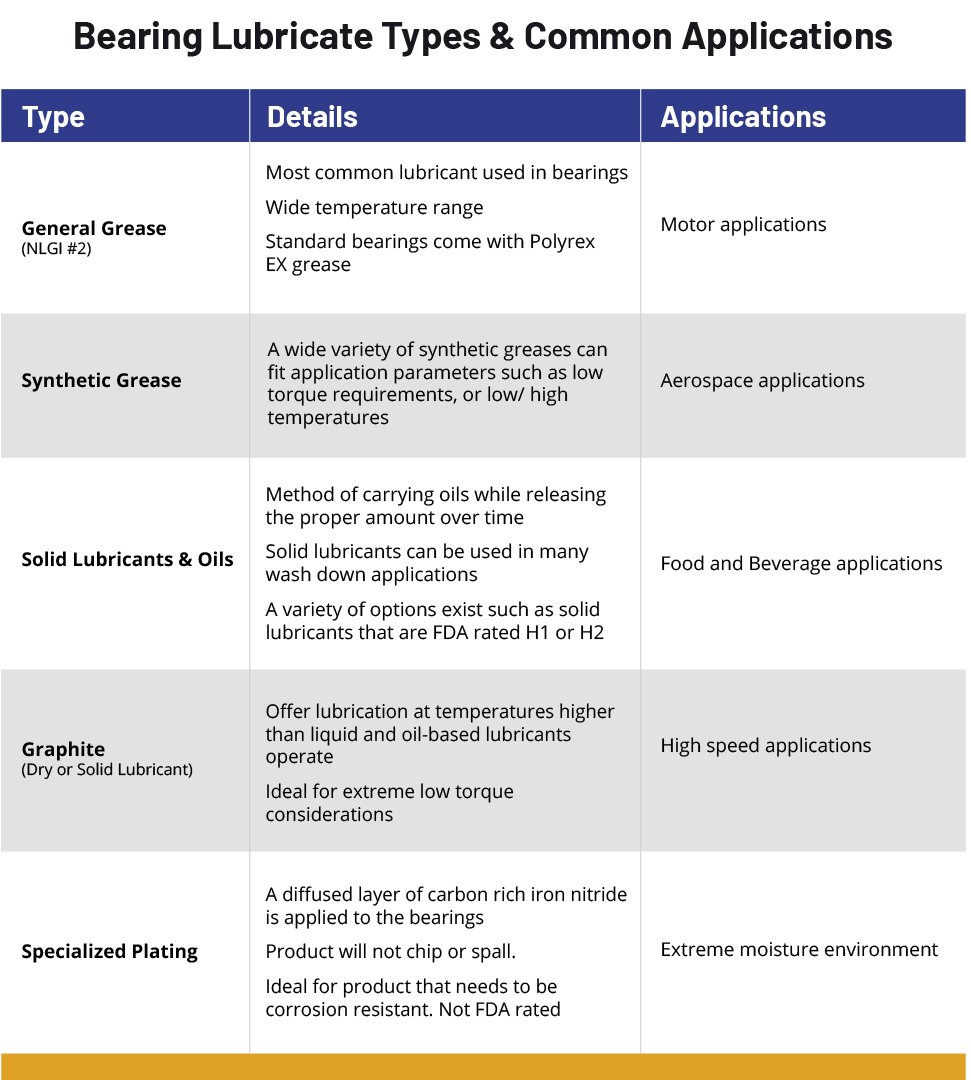

Still not sure where to start? Here's a handy chart that goes into more detail about common bearing lubricant types & common applications.

"Engineers express fluid resistance to flow in Saybolt Universal Seconds (SUS) and centistokes (mm2/sec, cSt). The difference in viscosity at different temperatures is the viscosity index (VI)."

Bearinggreasetypes and grades

A common type of splash feed lubrication is an oil ring system. This type of method reduces bearing operating temperature and is great for applications running at higher speeds and temperatures.

Audible feedback alone doesn't work because it's too subjective to pull any real conclusions since no two people hear the same thing. It's also too difficult to remember what a bearing could've sounded like months ago based on memory alone.

Viscosity is one of the key characteristics when specifying the right oil for a bearing. A good rule of thumb: low-viscosity fluids are thinner like water, and high-viscosity fluids are thicker like molasses.

The correct lubricant quantity can be determined by the operating speeds, design, reservoir volume, and the extent of sealing or shielding found in the application.

The base in synthetic oils is usually polyalphaolefins (PAO), polyalkylene glycols (PAG), esters, and silicones for cold and low torque conditions.

In fact, the lack of proper bearing lubrication is commonly regarded as one of the most common causes of bearing failure.

Now that we've learned more about the different types of methods you can apply the lubricant, let's dive in to the proper application procedure.

Incorrect grease - Make sure to use the correct grease for your application. Some applications need non-extreme pressure (non-EP) or general purpose (GP) grease, while others may require extreme pressure (EP) grease, according to Machinery Lubrication.

8613869596835

8613869596835