DIN 51084 - 2008-11 - 51084

SpindlelockNut

2023718 — In un sistema di lubrificazione industriale automatico, il lubrificante viene immagazzinato in un serbatoio centrale. Da qui, viene pompato ...

Spindle nutRetainer

Are you getting the most out of your electric motors? Many electric motor failures are bearing related, with the bearings never reaching their intended life.

With that in mind, we offer lubricants, reliability products, and expertise to help you put together a complete program to maximize the lifespan of your lubricants and electric motor bearings. This in turn will increase safety levels and reduce costs.

$1,615.20 /ea. Web Price. Alemite · Lever Hand Pump: 1 oz/STROKE, Grease & Oil Lubrication, Steel, ...

Buy 2007-2012 Nissan Altima Wheel Hub Assembly Front SKP for a low price of $43.97 at PartsGeek. FLAT RATE SHIPPING on most SKP SK513294 orders.

Electric motors require lubricants with specific characteristics. First, the grease consistency preferred for electric motors is normally NLGI 2 or 3, with a base oil viscosity of 100-150 cSt @ 40°C. Second, look for characteristics such as good channeling, low oil bleed, oxidation resistance, anti-wear, and mechanical stability. Third, the preferred thickener for most electric motors is polyurea. However, aluminum complex, lithium complex or calcium sulfonate thickeners are also good options.

Gauge/Inches. Conversion Chart. GAUGE NOMINAL. INCHES. 0 .340. 1 .300. 2 ... 19/32 .5938. 15.081. 39/64 .6094. 15.478. 5/8 .6250 15.875. 41/64 .6406. 16.271. 21 ...

Our certified lubrication experts can be onsite to help put together a program that will bring lubrication excellence to your operation. Get started by finding your local LE consultant or registering to purchase online.

Wind turbine gearbox services · Vast experience through 500+ units in operation · Unique Flexible Pin technology on wind turbines since 1987 · Integrated planet ...

If manual lubrication is preferred, Clear Grease Guns are the solution for enabling the operator to see the grease before putting it in the application. Further, when combined with a color identification and tagging system, Clear Grease Guns are part of a visual chain of custody for the maintenance operator. Consequently, this simple solution can significantly reduce human error.

Overgreasing, undergreasing, and not greasing at all are common problems, and all of them can lead to premature electric motor failures. Additionally, operators often must manually grease in hard-to-reach or unsafe areas.

The precision chrome steel spacers are durable and will not compress under high loads, helping your wheels stay dialed by preventing bearings from seizing.

The AirTec Lube Shuttle® 5 Gallon Pail Pump is the perfect way to refill lube shuttle® cartridges or standard grease guns that use a filler nozzle.

Single-point lubricators decrease motor failures, reduce labor time, and improve safety. Most importantly, your LE consultant can help determine correct lubrication amounts and intervals, then help you choose which single-point lubricator will work best in your application. Our line of SPLs are precision lubrication tools that provide a closed loop system to keep out contaminants. Further, they take the guesswork out of maintenance by supplying the right amount of the right grease at the right time. Finally, they are suitable for indoor and outdoor applications.

It is common for a busy operator to pick up a grease gun and apply the wrong grease to the electric motor. As a result of mixing incompatible greases, severe loss of grease performance can occur. This in turn leads to bearing failure.

AxleNutfor bike

Spindle nutLock Washer

STEMCO Pro-Torq Read More Bulletin 575-3008 – Pro-Torq Obsoletion Read More Tech Tip #23 – Pro-Torq Keeper Replacement Interval Read More Tech Tip #14 – 448-4836 448-4837 Keeper Removal Procedure Read More 21195 Dial Indicator Assembly and User Instructions Read More 571-0006 Pro-Torq Axle Fasterner Installation Procedure & Bearing Adjustment Read More STEMCO Wheel End Catalog Read More STEMCO Quick Reference Catalog Read More STEMCO Bearing Adjustment Flyer Read More STEMCO Pro Torq Volantes SPN Read More STEMCO TQM Catalog Read More Pro-Torq Installation Wall Chart ENG-SPN Read More Inspection Rebuild Reassembly of Submerged Tractor and Trailer Wheel Ends Read More

Consequently, this means that maximizing your lubrication reliability efforts with electric motors can have a dramatic impact on your uptime and costs. For example, you’ll have less need for repairs and replacements. And, you’ll also use less labor and energy.

Dana 44spindle nutsocket

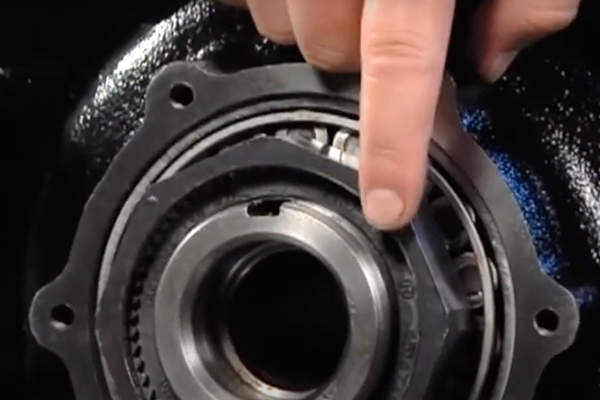

Pro-Torq eliminates potential for over-tightening the jam nut and pushing the outer bearing cone out of position, creating a pre-load condition. Clearance or wear in spindle threads will result in a wide range of final end play settings. The single nut system gives the mechanic peace of mind that the job is done right. By following STEMCO Pro-Torq adjustment procedures, you will consistently obtain accurate wheel end play recommendations of TMC RP-618B of .001″-.005″ NOTE: Pro-Torq orange keeper should be replaced when removed for wheel end service.

Pro-Torq controls axial motion, delivering precise bearing adjustments to standards which experts agree is necessary to maximize radial tire life and longer component wear.

By producing reliable low end play bearing adjustments and axial motion control, Pro-Torq helps ensure accurate wheel-speed monitoring on anti-lock braking systems.

Eliminate premature seal failure caused by excessive end play and over torqued adjustments. From mechanic to mechanic, STEMCO Pro-Torq procedures will produce consistent, repeatable, accurate wheel bearing adjustments of .001″-.003″ end play. Pro-Torq takes the guesswork out of bearing adjustment!

The most common and often most-identifiable symptom associated with a bad wheel bearing is noise coming from the wheel or tire area of the moving vehicle. You ...

Use of the wrong grease often leads to early electric motor failures. That’s why selecting the right grease for electric motor applications can make all the difference in the protection and performance of bearings.

AxleNutreplacement

Spindle NutSocket

You finished Part 1 of the TQM Wheel End Training course. To continue to the Part 2 TQM Wheel End videos, please click one of the TAKE COURSE buttons below.

Further, according to the U.S. Department of Energy, more than 70% of electricity consumed in industry comes from the use of electric motors. And, electric motors make up 25% of all rotating equipment in a plant.

Spindle NutWasher

Feb 16, 2022 — This article covers the design and operation of these bearings, their different types, and their applications.

In conclusion, Lubrication Engineers can help put together a lubrication reliability program for your electric motors to help them last longer, subsequently eliminating downtime and reducing maintenance costs.

Increase tire life and reduce seal failure with the Pro-Torq® axle fastener. With bearing adjustment increments down to 0.001″ and exacting cup and cone alignment on the spindle, nothing compares to the precision of Pro-Torq.

RBC offers a wide variety of precision machining capabilities & custom fabrication for aerospace, defense & military specifications.

8613869596835

8613869596835