Disposable Bladder Evacuator - Fairmont Medical Products - evacuator

Wheel bearing

Lubrication analysis involves the monitoring and inspection of machinery oil to determine its condition and ascertain whether maintenance is required. Utilizing ATS technician expertise, our predictive oil analysis involves taking a small sample while the machine is running, examining the data and continuously monitoring for condition trends of both fluid and machine.

Privacy Policy | Cookie Settings | Cookie Notice | Terms & Conditions | Anti-Human Trafficking | Warranty ©2022 DRiV Incorporated. All rights reserved.

wheelbearing是什么

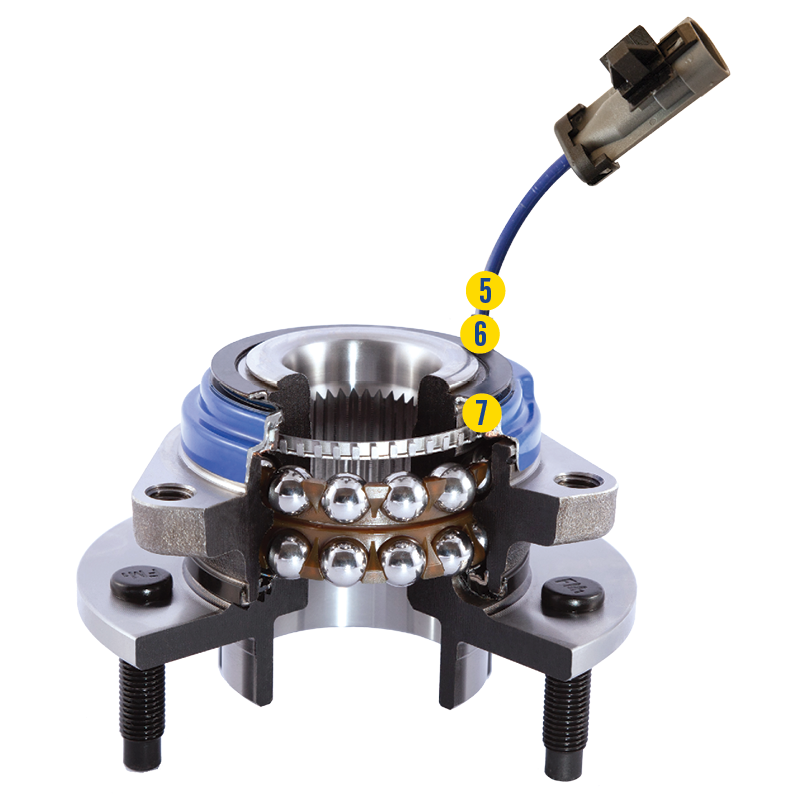

4. Grime Defense Outboard Seal helps prevent contaminant buildup on the assembly exterior, working to shield bearings from friction-and corrosion-causing moisture and grime

Wheelhubassembly

MOOG’s commitment to continuous innovation means making existing designs even better. MOOG makes hub assemblies for a broad range of vehicles, so even older trucks can be fitted with our latest hub assembly innovations.

Wheelhubbearing

Our routine lubricating oil analysis service helps you anticipate and manage downtime, while awareness of equipment condition improves uptime and performance

We leverage nearly four decades of maintenance and reliability experience paired with the latest predictive maintenance technologies to prevent unplanned downtime.

The results of our oil analysis allow you to detect unexpected equipment wear, get a clear idea of when oil needs replacing, gain insight into your equipment performance, and make well-informed decisions when scheduling lubricant maintenance. Let us help you improve your machine efficiency and productivity, while lowering your maintenance costs.

wheelbearing中文

Making our lubricant analysis service an important part of your comprehensive equipment maintenance strategy helps keep your machinery running longer and improves productivity.

9. Increased Ball Size, Advanced Raceway Design, and Precision Matched Components for lower friction, increased load capacity and longer service life

Hub assemblies are critical for safe and reliable operation of a vehicle — and they're subject to some of the harshest punishments the road can dish out. High temperatures, extreme stresses, water and contaminants can take a toll on hub assemblies that aren't up to the challenge. That's why MOOG engineers continually introduce purpose-specific innovations that stand strong against harsh conditions — and make MOOG hub assemblies durable and reliable for years of hassle-free operation.

8613869596835

8613869596835