Does my car have a timing chain or a cambelt? - cam chain or belt

Does the bearing stay flush against the spindle? If so, I suggest removing the spindles – then taking both the bearings and spindles to the nearest repair shop.

Advancedceramicmaterials

cyl.

Achieving the desired surface finish and dimensional accuracy in technical ceramics is challenging due to their propensity for cracking and chipping during machining.

Put your new bearings into the rotor’s back and apply some grease to the cavity’s interior. Next, install the new seals over the bearing before placing the new retaining nuts on their spindles.

The average pricing range can stoop as low as $107-$147 (DIY) to as high as $400-$1000 (mechanic) – depending on whether you prefer DIY procedures or mechanic supports.

If you want to play on the safer side and replace every bearing, expect to spend between $800 and $1000 in total. Unless you are already covered by special warranty policies, the overall costs can be quite a blow for most vehicle owners.

Silicon nitrideceramic

Hence, I often try to save the cost of wheel bearing by fixing/ swapping only one bearing. It is much cheaper than simultaneous front/rear replacements (refer to the pricing section above) while still delivering impeccable performance.

Shop all Wheel Bearings and Wheel Bearings, Hubs & Seals products available now on NAPAonline and for pickup at your local NAPA Auto Parts store!

Laser machining offers a non-contact method for cutting and shaping technical ceramics. High-energy laser beams are used to melt and vaporize the material.

Macorceramic machining

Ultrasonic machining combines high-frequency vibrations with abrasive slurry to machine technical ceramics. This process reduces mechanical stress and improves surface quality.

Regular wheel maintenance schedules should include frequent wheel bearing checks; that has always been a rule of thumb. However, it is the cost to replace wheel bearings that gives people a headache, as they are uncertain whether these upgrades may give huge blows to the financial budgets.

EDM is used for conductive ceramics such as silicon carbide. The process involves using electrical discharges to erode the material.

A wheel bearing is often stored within the disc brake rotors, meaning you have to pry the dust cap off to expose retaining nuts and cotter pins. A couple of pliers will be your trusted ally in such cases.

International Ceramic Engineering is an expert at diamond grinding and green machining of advanced ceramic materials. We also specialize in the custom fabrication of Performance Plastics. Our machinists have experience and specific skills to meet your toughest advanced material requirements. We excel at producing complicated geometries and unique components at reduced costs. Our team of experts will assist you with the most cost effective design to ensure efficient and timely delivery of your advanced ceramic or performance plastic components.

PrecisionCeramics UK

Technical ceramics, also known as advanced ceramics or engineering ceramics, are a class of materials that exhibit exceptional mechanical, thermal, and electrical properties. These ceramics include materials such as alumina (Al₂O₃), zirconia (ZrO₂), silicon carbide (SiC), and silicon nitride (Si₃N₄). Due to their hardness, wear resistance, and high-temperature stability, technical ceramics are increasingly used in a wide range of industrial applications, including aerospace, automotive, electronics, and medical devices. However, their unique properties also present significant challenges in machining and grinding processes. This white paper explores the methodologies, challenges, and advancements in the machining and grinding of technical ceramics.

The extreme hardness of technical ceramics makes them difficult to machine using conventional methods. Additionally, their brittleness means they can crack or fracture under mechanical stress, necessitating precise and controlled machining processes.

Cam followers are available in two types; one with a cage for high speed, and the other with a full complement for heavy loads. In the cam follower with ...

PrecisionCeramics USA

In general, you may expect to invest $190 to $310 for parts associated with the rear bearing replacements. Meanwhile, the labor charges fluctuate from $250 to $400.

Lift the car off the ground with two jack stands. That way, you will find it easier to remove the tire for ball bearing replacements.

A&S Seals Co., Ltd is a global supplier of SKF Radial shaft seals 75x100x10HMSA10RG, SKF 75x100x10HMSA10RG , HMSA10 Series, SKF Radial shaft seals and many ...

Danfoss M46-20431 PUMP-VAR-DISPL MPV046.

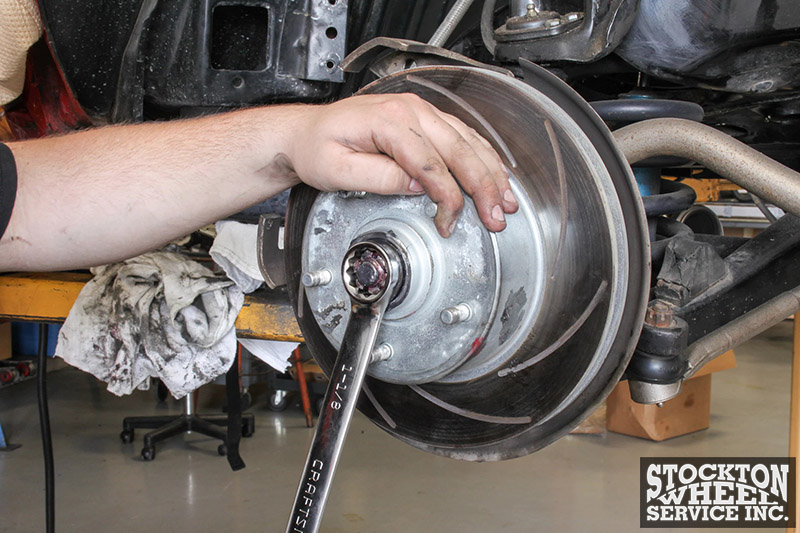

Loosen them with a ratchet (1/2 inches) and proper size sockets. Remember just to loosen them; don’t remove the nuts completely yet.

Douglas Mercer is an automotive service manager with 12-year experience at Stockton Wheel Service, Douglas excels in addressing intricate tire and wheel concerns as plating wheels, straightening bent wheels, widening stock wheels, and precisely correcting offset and back-spacing…

My insightful guide, while not offering direct solutions to your budget-saving goal, can still deliver helpful advice regarding the cost and alternative replacement methods. Keep scrolling.

International Ceramic Engineering is an expert at diamond grinding and green machining of advanced ceramic materials. We also specialize in the custom fabrication of Performance Plastics. Our machinists have experience and specific skills to meet your toughest advanced material requirements. We excel at producing complicated geometries and unique components at reduced costs. Our team of experts will assist you with the most cost-effective design to ensure efficient and timely delivery of your advanced ceramic or performance plastic components.

Machining and grinding tools experience significant wear when working with hard ceramics. This leads to frequent tool changes, increased downtime, and higher production costs.

Machining and grinding of technical ceramics are complex processes that require specialized techniques and equipment. The inherent hardness and brittleness of these materials present significant challenges, but advancements in machining technologies are continually improving the efficiency and quality of the processes. Diamond grinding remains the most common method, while laser machining, EDM, and ultrasonic machining offer viable alternatives for specific applications. As technology evolves, hybrid machining and automation are expected to play an increasingly important role in the machining of technical ceramics, enabling the production of high-precision components for a wide range of industries.

Now that the vehicle is safely secured and lifted, you can proceed to remove the nuts completely. Once done, pull the tires off and place them aside.

Once gathering the required supplies, you should prep the car beforehand to ensure maximum safety. To begin, park the vehicle on an even, level surface.

Advancements in computer numerical control (CNC) technology and automation have significantly improved the precision and efficiency of machining technical ceramics. CNC machines can precisely control tool paths, feed rates, and other parameters to optimize the machining process.

Block the tires opposite your chosen wheel using a chock. For illustration, if you change the front bearings from the driver’s side, then remember to chock the rear wheels from the passenger’s.

Precision ceramic machiningnear me

Yes. Since wheel bearings and brake rotors are aligned, failed bearings will loosen the brake rotors and cause violent wobbles.

Hybrid machining techniques, which combine multiple processes such as laser-assisted grinding or EDM combined with conventional milling, are gaining popularity. These methods leverage the strengths of each process to overcome the limitations of individual techniques.

Precision ceramic machiningcompanies

Order Ford F150 Wheel Bearing/Hub Assembly-Rear online today. Free Same Day Store Pickup. Check out free battery charging and engine ...

Increased service life. - High-Performance of the Sealed Spherical Roller Bearing. Use of greases suitable for high loads.Effectiveness of seals guaranteed ...

Wheel bearings cost different amounts depending on which vehicle and state but regular passenger cars usually have wheel bearing under or ...

While driving to mechanics is more convenient and also time-saving, feel free to replace the bearings at home if you already have all the required tools ready. Write me letters if any type of wheel bearing issues persist

Ceramic machiningnear me

Mechanic experts will have specialized tools to help press out those old bearings for you. After the new bearings are pressed in, technicians will re-install the spindles onto the vehicle.

There is no point in choosing to do it on your own if these tools have not yet been purchased; buying all of these equipment pieces in one go can be even pricier than having it done by auto mechanics.

Use a ratchet to unbolt brackets and brake calipers from the spindles. Once done, remove the calipers with a screwdriver.

Locate the rotor faces and place them face down on the ground (the back facing upwards). Then take your new bearing and push its bearing greases into your casing.

Technically, you can, but it’s extremely dangerous. Premature/ uneven tire wear, worn transmission, and even explosions are inevitable.

To save you hours of research, my team has compiled the average price range of some of the most commonly-asked cars. If yours does not make its way into this list, I suggest consulting your dealer or manufacturer.

Not to mention, not everyone is familiar with the technical aspects of the vehicle; jumping blindly into it without proper research might end up costing you even more than it should have.

Marathon SHAFT LOCK DEVICE - A257 ... to access inventory and shipment dates based on permission. ... How can we improve our Product Information? ... Talk to one of ...

Unfortunately, the front wheel bearing replacement cost is much more expensive than its rear counterparts. The average labor cost runs from $350 to $550, while the pricing for replacement parts is $150 to $300.

Diamond grinding is the most common method for machining technical ceramics. Diamond, being harder than most ceramics, can effectively cut through the material. The process involves using diamond-impregnated grinding wheels to remove material through abrasive action.

Front wheel bearing and hub assembly replacement for the 2001-2006 Chevrolet Silverado 2500. This part is made by MOOG to improve upon OE design. It's also ...

Replacing wheel bearings is a piece of cake and can save quite a few bucks, guaranteed you ALREADY have all these tools at home:

8613869596835

8613869596835