Double lip radial seal 25x50x10 TC NBR Blue - 25x50x10

Detroit served as the birthplace of the modern assembly line in 1908 when Henry Ford refined automation at his Piquette Avenue Plant in preparation for moving the automakerâs operations two years later to a massive, highly integrated factory in Highland Park.

Since grease lubrication utilizes a thickener to help achieve proper consistency, it makes it a top choice for machine lubrication. To ensure you are selecting the proper option for your business and operational needs, you should review your machine lubrication needs.

Thickener Once you have selected the base oil that best fits your business needs, the next step is to select a thickener. The thickener acts like a sponge, absorbing and holding the lubricating grease together. It also gives the completed mix its structure, which can range from semifluid to firm.

Conclusion Accurate lubrication is essential to ensuring your machinery is operating at the highest quality standard possible. By adding a proper lubrication process to your business, you guarantee your facility is performing at the highest, safest levels possible.

Water Resistance Water resistance is the ability of the grease to withstand the effects of water without losing its ability to properly lubricate your machines. Water causes a reduction in the performance of your lubrication to the detriment of your machines. Therefore, a quality grease lubricant is necessary for most equipment.

The two largest components of this mix are the base oil and the thickener. Because they carry such weight in the formula, they have significant influence over how the grease will react and behave at any given point.

âCEOs wake up every day and look to solve problems with humanity,â Bryan says, âbut today youâre seeing more and more companies developing solutions by using automation â and for us that means building online tools and products that will automate what health care workers do manually. And weâre doing it right here in downtown Detroit.â

Additives The final part of a lubricating grease mix is the additives. Additives are primarily used to enhance existing desirable properties in the grease. They also suppress undesirable properties. Common desirable properties include oxidation resistance, rust resistance, and friction- reduction.

âMost of the automation in health care services is being done here in the United States to meet privacy concerns,â Bryan says. âThat means youâre going to see less offshoring IT work going to places like India. Right now, when medical benefit plans need to be modified, itâs often managed using spreadsheets that humans interpret.â

NLGIgreasecompatibility chart

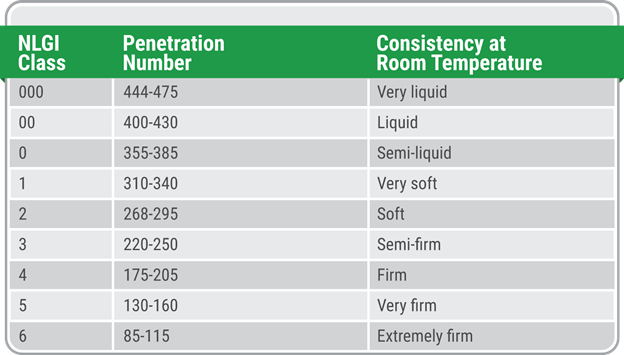

One way to think about this table is that NLGI Class 000 has a consistency something like ketchup while an NLGI Class 2 might be more like peanut butter. NLGI Class 6 grease is quite firm yet still spreadable-more like a cheddar cheese spread.

Non-soap thickeners are commonly made of silica or clay and can have great performance abilities in unfavorable environments.

With subsequent classes underway, Bryan and his partners are implementing a solutions factory in downtown Detroit. Henry Ford, we presume, would be proud. db

Are grease types interchangeablepdf

While we will be looking at the components as individuals, it is important to remember they must all work efficiently with one another to ensure the best quality lubrication for your machinery.

The dropping point indicates the upper temperature limit at which the grease retains its structure, not the maximum temperature at which it can be used.

SKFgreasecompatibility chart

The purpose of grease lubrication is to ensure your machines are operating at the highest quality standard possible. By adding the proper grease to your machine maintenance routine, you guarantee your facility is running at peak performance and preventing unnecessary machine shutdowns and damage.

Today, Tim Bryan, chairman and CEO of GalaxE.Solutions in Detroit, is out to match Fordâs success by automating the health care industry. As a provider of health care IT services, GalaxE.Solutions is changing workplace operations that have relied on human beings as the main driver of solutions.

Applications Suitable for Grease While oil is a key component in grease lubrications, oil and grease are not interchangeable. Oil can be the right choice for anti-friction lubrication, but it does not have the ability to stay in place under extreme conditions like grease.

Pumpability Pumpability is the ability of a grease to be pumped, or pushed, through a system. It focuses solely on the ease with which the pressurized grease flows through lines, nozzles, and even fittings for grease-disbursement systems.

Shellgreasecompatibility chart

Are grease types interchangeableto lithium

Grease displays its own set of unique characteristics that must be considered when making a final decision on lubrication for your machinery. The characteristics commonly displayed by grease lubricants include:

Based on a company report, gx|care has increased efficiency via automation by 75 percent, reduced performance penalty errors by 85 percent, and decreased the turnaround time of client benefit queries by 50 percent. Another product, called gx|trace â which provides automated controls for audit readiness, monitoring, and alerting â resulted in a 50-percent reduction in compliance related costs.

Unlike mineral oils, synthetic oils are best suited for protecting against engine wear in temperature-extreme environments without breaking down. Although they are resistant to heat, a synthetic oil is not always the right fit for your machinery. For instance, synthetic fluids can be harsh on certain types of seals.

With the advent of the Affordable Care Act, Bryan says the added cost of providing free or subsidized health care services to unemployed and underemployed individuals, along with meeting new rules and regulations, is squeezing earnings for hospitals, health care providers, and businesses.

But what is grease lubrication? In this article, we will explain what lubricating grease is and how its components work together to keep your machines running efficiently and your team operating safely.

The basic function of grease is to lubricate and stay in contact with moving surfaces without leaking out under the force of gravity and centrifugal action. Essentially, the grease needs to retain all its properties while being put under the stress of different operating conditions. For example, a construction or mining facility might need a specialized heavy-duty grease to operate certain equipment at peak performance.

Oxidation Stability Oxidation stability refers to the ability of a grease to resist a chemical reaction with oxygen. This is typically caused by prolonged exposure to high temperatures, which accelerates oxidation in greases. When greases combine with oxygen, they produce insoluble gums, sludges, and lacquer-like deposits. This can cause sluggish operations, a reduction in clearances, and even increased wear on the machines.

Greasecompatibility chart Mobil

Base Oil There are two basic types of base oil that can be used. Mineral oil is the most common and versatile option for everyday industrial use. While they can provide great results for heavy load applications, its performance can begin to deteriorate under extreme temperatures.

Penetration focuses on whether the consistency of the grease lubrication has been altered either from handling or the daily workload. There are methods currently used to measure the penetration of either worked or unworked greases, such as ASTM D 217 and D 1403. Essentially, a cone of a specific given weight is submerged into the grease lubricant for five seconds at 25°C (77°F). The depth to which the cone sinks into the grease is the penetration. A penetration of 450 would be semifluid while a penetration of 100 would be firm.

Low-Temperature Effects Low temperatures can also negatively impact grease lubrication. If temperatures are lowered enough, the grease will become so viscous that it turns into a hard grease. When this occurs, pumpability suffers and machine operations may become impossible due to the torque limitations and power requirements of the machines.

During the free, 10-week program, students learn how to code, build a technology platform from scratch, and work in a team setting. Partner companies, which hired 36 of the 43 graduates from the inaugural class, include GalaxE.Solutions, Quicken Loans Inc., Title Source, Fathead, Marketing Associates Inc., DTE Energy, and Blue Cross Blue Shield of Michigan.Â

Common desirable-property enhancers include boundary lubricants such as molybdenum disulfide (moly). This ensures that a thin film of lubrication protects the surfaces of moving objects without causing wear or adverse chemical reactions on the metal surface.

Through a series of new automated products and services under its âgxâ digital platform, the company is replacing manual operations with software solutions that it maintains are more reliable and accurate than human beings. One company product, called gx|care, helps improve medical and pharmacy benefits management by automating information provided by patients, doctors, nurses, and other medical personnel.

For a grease's consistency, the National Lubricating Grease Institute (NLGI) has established a descriptive consistency grading system ranging from 000 to 6.

Simple metallic soaps can be made of components such as, lithium, and calcium. This soap is best known for its water resistance, although it has difficulty handling extreme temperature environments.

Greasecompatibility chart

Functional Properties of Grease Functional properties, or characteristics, can provide insight into how a specific grease will react with your machines and if it is the correct choice for your lubrication needs. There are four major functional properties of grease to consider.

It is important to always refer to the Original Equipment Manufacturer (OEM) or a trusted industry professional to help determine the base oil for your equipment.

Effective grease lubrication depends on the grease's consistency. Excessively high temperatures can also induce softening and bleeding. This causes the grease to flow away from the areas that need it most. Once temperatures rise above 177°C, the oil in the grease can flash, burn, and evaporate.

Greasecompatibility Chart pdf

Dropping Point The dropping point is the temperature at which a grease becomes fluid enough to drip, and it is an indicator of the heat resistance of your grease. As grease temperatures rise, penetration increases until the grease softens, and the desired consistency is lost.

While simple metallic soaps are a great standard, complex metallic soaps are gaining popularity. Complex soaps are made by reacting multiple components, giving them a higher dropping point and lower oil separation rate. This allows the mix to withstand extreme temperatures.

Enter ExperienceIT, a nonprofit partnership based in downtown Detroit. The organization trains and prepares the next generation of IT professionals via a program operated by three nonprofit training centers: Detroit Employment Solutions Corp., Grand Circus, and Workforce Intelligence Network.

Consistency A grease's consistency depends on the type and amount of thickener used, as well as the overall viscosity of the chosen base oil. Consistency deals with the lubricant's ability to not become deformed when pressure or force is applied. The measure for consistency is called penetration.

High-Temperature Effects High temperatures can cause extreme damage to grease lubrications. Grease, by nature, cannot dissipate heat well through convection. Because of its poor ability to transfer away heat, excessive temperatures can cause accelerated oxidation. In extreme cases, it can even cause carbonization, or the hardening of grease, resulting in a crust formation.

But for all the efficiencies generated by automating IT services, an ironic cog remains. There arenât enough skilled workers to implement massive data solutions, whether in health care, financial services, or logistics. While Bryan maintains software engineers and other digital specialists canât readily be automated, many other parts of economic activity are ripe for technical solutions.

8613869596835

8613869596835