EducationUSA | - usa

——Speed Requirements: Bearings must be compatible with the operational speed of the machinery. And the bearing performance is not affected.

Flange bearing

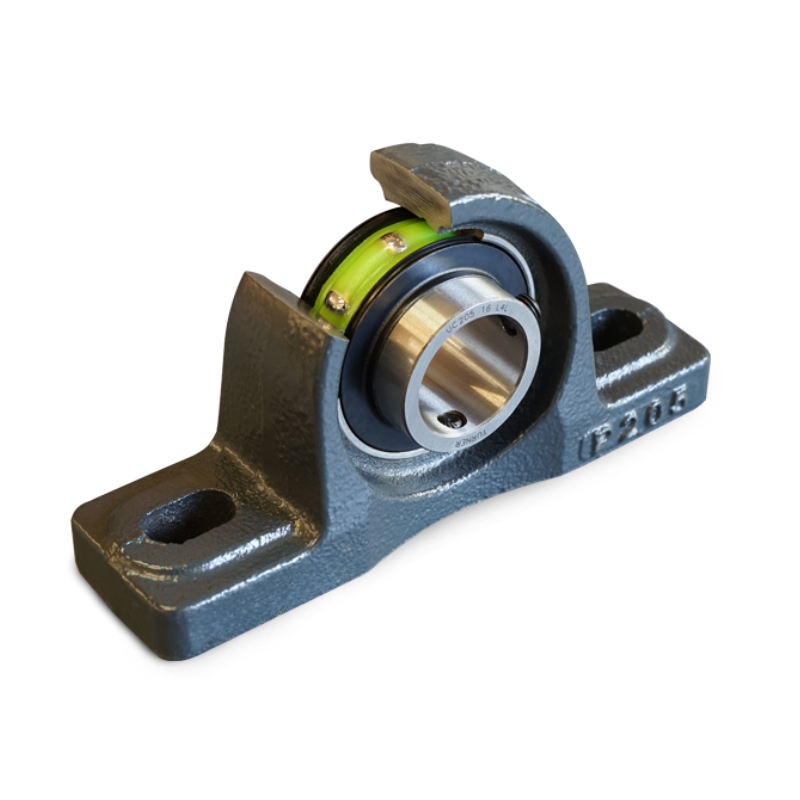

In mounted bearings, the bearing is mounted in a housing to facilitate a variety of applications. Let’s explore the different types of mounted bearings and their design features.

Jan 13, 2017 — These roller bearings require an SAE 8620 steel camshaft. 8620 steel is known for its ability to absorb the carbon necessary to harden the steel.

New EU legislation requires us to inform you that we use cookies. Our use of cookies is limited, but you may wish to read our policy before continuing. Please click OK to dismiss this message.

——Operating Environment: The operating environment of the bearing will affect its design and material selection. Materials with strong sealing and corrosion resistance should be selected to prevent corrosion by the environment.

Bearing mount types

Mounted Linear BearingsCommonly used in applications that require precise linear motion, such as automated machinery and robotics, these bearings are designed to reduce friction and allow smooth movement along a linear shaft.

We and selected third parties use cookies (or similar technologies) for technical purposes, to enhance and analyze site usage, to support our marketing efforts, and for other purposes described in our Cookie Policy

——Temperature Ranges: The operating temperature of the bearing is also an important consideration. When used at high temperatures, select materials that are resistant to high temperatures and lubricants that will not degrade due to high temperatures; at low temperatures, the bearing must not become brittle, and the lubricant must remain effective to ensure that it does not become stiff during operation.

Thank you! We aim to offer detailed explanations and practical solutions for understanding mounted bearings. Our goal is to help you make informed decisions with clear and accurate information. Feel free to ask any questions!

2024119 — Hub seals are "cartridge" or "unitized" in that they're two separate components that are locked together. The case has an interference fit into ...

In summary, by properly selecting and maintaining the mounted bearing, you can not only improve mechanical efficiency and reliability but also reduce downtime and operating costs. As technology advances, keeping up with the latest developments in bearing materials and designs will further improve equipment performance.

Flange Mounted BearingsFlange mounted bearings are versatile and are used to provide support for shafts that run perpendicular to the surface to which the bearing is mounted. Comes in a variety of shapes including square, round, and oval.

Browse Item # UEL313-208, Bearing Insert w/ Eccentric Locking Collar, Wide Inner Ring - Spherical O.D. in the NTN Bearing Corp. of America catalog including ...

Jan 2, 2006 — - What are the signs of a bad axel/wheel bearing? Noises ... It's usually possible to isolate a noisy front-wheel bearing by cornering with both ...

To select suitable mounted bearings to ensure efficient operation of the machinery, the following factors need to be considered:

Pillow blockbearings

PRODUCT INFO BR7 was designed to provide more effective utilisation of aluminium with its span vs. economics element. BR7 can also be manufactured in steel.

Mar 15, 2011 — Here's the definition, right out of the NRA Firearms Sourcebook. It is ...the minor interior diameter of a barrel that is the diameter of a ...

ManufacturingIn manufacturing, especially with heavy machinery, mounted bearings must support high loads and operate under high stress without compromising performance.

Mining and ConstructionApplied in cranes, or excavators, these industries often use mounted spherical and tapered roller bearings because they can withstand misalignment, heavy loads, and shocks. The bearing housing is strong and durable to protect the internal components.

Mounted bearing housings are typically made from materials such as cast iron, stainless steel, and various plastics like thermoplastics, each selected based on specific operational and environmental criteria.

Mounted Sleeve BearingsSleeve bearings, also known as bushings, are typically made of soft metal or composite materials that allow the shaft to slide freely within the sleeve. Suitable for low-load applications.

FlangeMounted Bearings

AgricultureTo ensure operation in harsh environments, mounted bearings usually have strong sealing technology and corrosion-resistant materials to prevent dust pollution and corrosion caused by humidity, so that tractors, harvesters, and other machinery can operate stably.

Mounted bearings play a key role in the seamless operation of various industrial machinery and systems. These components support and guide the rotation, ensure accurate alignment, reduce friction, and promote the effective transmission of power between different parts of the machine. This article explores the mounted bearing in-depth, studies its various types, its wide application in different fields, and the selection criteria of the mounted bearing so that you can make an informed choice of the mounted bearing.

... Precision Bearing Balls > Page 1 of 2. Precision Bearing Balls. Browse: All items, Balls, Precision Bearing Balls. Sort by: Featured, Price, low to high, Price, ...

Our Victor Reinz valve stem seals protect from the fouling of exhaust after-treatment devices caused by an increase in hydrocarbon and particulate emissions ...

Red Stainless Steel Car Seals Pack of 100. £ 148.00 Exc. VAT. SKU: CLO-1000/2.5PTRED-SS. View Item. Add to Quote. This product is already in your quote request ...

MountedBall Bearing

Insert BearingsInsert bearings feature a spherical outer diameter and are designed to fit into corresponding housing, which is usually a casting that allows the bearing to pivot within the housing, with a self-aligning function.

By understanding the different types of mounted bearings, each bearing has its own unique design features to meet specific operating needs. When selecting the right mounted bearing, focus on these factors, including load capacity, operating speed and environmental conditions, to ensure that the bearing can withstand the operating stress without failure. It can work efficiently at the expected speed during operation, and the appropriate materials are selected to minimize friction and heat generation. Each material has its own unique advantages and should be fully considered the operating needs of the application.

The characteristics of mounted bearing housings play a key role in improving performance and service life. The right bearing housing ensures that the bearing is aligned with the mechanical load, thereby reducing wear and improving efficiency. It also protects the bearing from external contaminants such as dust and moisture. In addition, the heat dissipation ability of the bearing housing prevents the bearing from overheating, helping to maintain lubrication and structural integrity. A strong bearing housing absorbs vibration and shock, protecting the bearing from external shocks and load fluctuations. The combination of these factors means that selecting the right bearing housing is critical to optimal performance and extended service life of the mounted bearing, ensuring that the machine can operate reliably under different operating conditions.

Vintage Electronic Singer Sewing Machine 6212C With case and Power Cord + Foot Pedal Works Product Information Category Handmade > Patterns > Sewing Brand ...

Cast iron offers high strength, durability and good shock-absorbing properties and is often used in heavy industrial applications where robustness is key. Stainless steel is preferred in corrosion-prone environments, such as food processing or coastal areas, because it resists rust and chemical degradation while maintaining strength and durability. Thermoplastic housings, on the other hand, are lightweight, corrosion- and chemical-resistant and are often used in applications that require clean or sterile conditions. For example, in the pharmaceutical or food industries. The choice of these materials directly affects the ability of the bearing to operate under specific conditions, manage loads and resist environmental challenges, thereby ensuring reliability, reducing maintenance requirements, and extending the service life of the machinery. This careful consideration of materials based on environmental and operational needs helps maintain system integrity and operating efficiency in a wide range of applications.

We stock a range of solid and hollow steel balls and hemispheres. In addition, we also stock spheres with holes and blind or through threads, as well as crushed spheres. Our spheres are manufactured from fully weldable mild steel and can be galvanised unless shown as cast. Steel spheres are available in a huge variety of sizes and designs, suitable for almost any application for use on railings, fences and gates.

Mounted Roller BearingsUse cylindrical rollers as rolling elements, which increases the contact area with the raceway and allows them to withstand heavier loads.

Split BearingsSplit bearings are designed for ease of installation and maintenance, consisting of a split housing and a split inner ring. Often used in roll mills, conveyors, and marine propulsion systems where downtime needs to be minimized.

Food and BeverageIn food hygiene and safety, mounted bearings are made of stainless steel or corrosion-resistant materials. The sealing design in mounted bearings can prevent contamination and facilitate frequent flushing, meeting hygiene standards.

8613869596835

8613869596835