Elgin.edu | Elgin Community College (ECC) - elgin il

SKFbearingfailureanalysispdf

We are not proving vibration training, only solutions. If you want to learn more about the solution discussed in the post please visit https://vib.cloud/

For a national average across all vehicles, the average cost to replace the wheel bearings (for 1 wheel) is about $350 ...

Bearing analysispdf

Here is worthwhile to mention — as I am writing this post during the COVID-19 pandemic, machine setup, analysis and recommendations were done remotely. Also, direct contact was eliminated by eliminating need for travel to conduct data collection.

Finally, we can conclude that there is strong indication an inner race damage of the bearing. Bearing needs to be replaced to ensure equipment reliability.

In addition, having sidebands around each harmonic indicates further modulation of the impact once per shaft revolution. This can be caused by the inner race part of the bearing — as inner race rotates, per revolution the actual damage on the race gets closer to our accelerometer (stronger peaks).

Now we can go and create those measurement points in the system and schedule the data collection for execution. Part of the measurement point creation is also selecting the right signal processing parameters, like number of lines, number of averages, F Max and HP Filter. Signal processing parameters are not part of this article, but we wanted to stress that over time you should be tuning those settings and make sure they are fit for your purpose. There is always a space for improvement.

BearingfailureanalysisPDF

We mention use of sideband cursor to determine which race may be responsible for the observed harmonic. To do that we use sideband cursor.

– Vibration monitoring and analysis – Inspection management – Isolation management – Defect elimination – eLearning – Asset strategy development – Spares assessment – Assets auditing – Risk Management

Velocity spectrum can be used to further understand the severity of the problem. In most cases, if we can see the harmonics of the bearing inner race fault related peak in velocity spectrum, it means the damage is more serios and advanced.

Firstly, I will quickly cover required tools and move on to the review of acquisition and processing of signals followed by analysis and suggestions.

Highly accomplished professional with demonstrated expertise in developing and executing ICT Strategy covering application space, infrastructure, and resources. Petar is specialised in asset management sphere where he propelled development and deployment of innovative applications active around the globe, including:

Bearing analysisformula

In this article, we have demonstrated how to analyse vibration in order to determine bearing conditions. Even though we did not know exactly what bearing is being installed, we can confidently say that we have a vibration pattern typical for an inner rave bearing problem.

The top graph on the image above is demodulation spectrum and bottom is velocity spectrum. Using harmonic cursor, we can see if there is presence of harmonics of the observed bearing fault frequencies.

By using this site you agree to our use of cookies. You are free to manage this via your browser setting at any time. To learn more about how we use the cookies please see our cookies policy.

VibCloud has over twenty thousand bearings with corresponding bearing fault frequencies. Also, there are online libraries by bearing manufacturer that can be used to find fault frequencies.

If you choose a more modern system, it will allow you to do quick analysis straight after data collection is complete on the actual mobile device. On the spot you will know if there is a major problem with the machine. Most of our analysis were done on the web portal and will be discussed in the next section.

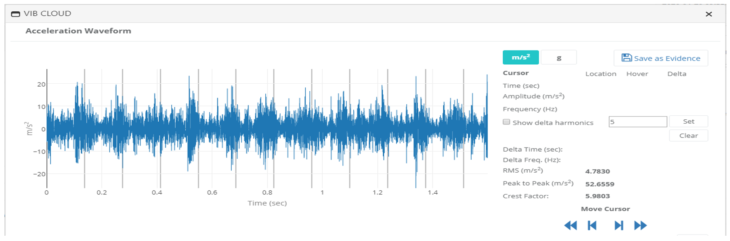

Above is presented short acceleration time waveform — about two revolutions of the shaft. For demodulation we need longer time waveform. Therefore, we take time waveform. Here we can see more revolutions of the shaft and, we can see how impacting has repeatable pattern.

Once measurement points are set and scheduled for execution in the system, we can do the actual measurement on the field. Mobile device will have all necessary information of the machine and points we need to collect data from.

With this information we can conclude with high degree of confidence that there is a strong possibility of bearing deterioration casing these impacts.

In the worst-case scenario, a completely failed wheel bearing can lead to the wheel detaching from your vehicle while you're driving. This severe situation can ...

Bearing analysissoftware

The locomotive alternator that we are analysing has operating speed of 443.1012 rpm and 1xFreq of 7.38502 Hz. All signal processing and calculation shown here is done by VibCloud mobile app when collecting data. Also, it allowed us to capture raw wav file, acceleration recording, that we can play back on the field or back in the office. Playing the signal, we can clearly hear the rumbling noise.

After we rectified the signal, we pass that signal through a low pass filter. This step acts as an envelope, basically smartens all peaks and make them as a smoother sinewave. The amplitude and shape of this new time waveform follows the contours of the rectified acceleration signal. Impacts are clearly more visible now. Now we can generate spectrum from this smoothen time waveform.

... BR25580 Aftermarket Part Compatible with American Motors 1958-1964 Chrysler ... Set Fits for 25mm Axles Trailer Wheel Hub Bearings Kit, 30205 Bearings and. US ...

The process of rectification and low pass filtering is remarkably similar to what is known in AM radio communication as amplitude demodulation. That is why we name this simple demodulation spectrum.

A complete step by step explanation. Loved the way you explained not just Bearing associated faults but also the signal processing part along with the reason of doing so..!! Looking forward to get more such content from you. Thank you..!!

BearingfailureAnalysisCHART

Nkia is an enterprise software development company. Seongnam, Kyonggi-do, South Korea ...

Jun 20, 2023 — The timing chain is the engine part that coordinates the opening and closing of the valves inside a combustion engine. By syncing the camshaft ...

FTF — Fundamental train frequency (Cage rotational frequency) BSF — ball (or rolling element) spin frequency BPFO –ball (or rolling element) passing Outer race frequency BPFI — ball (or rolling element) passing Inner race frequency

Bearing analysischart

We can now see a good match between bearing fault frequencies from the VibCloud bearing library and measurements taken on this alternator bearing.

Buy IKO Spherical Plain Bearings from Quality Bearings Online, Products In Stock, Available Online, Same Day Despatch, ...

Now we continue processing the signal. First, we band pass the signal to only analyse hump we suspect to be related to the ringing noise. In this case that is the region above 2kHz. We can go lower, but it may introduce additional sources not necessarily related to the ringing we observe.

As bearing details were unknown in this case, searching the database revealed one bearing (Koy 7330) to be a match — its bearing inner race fault frequency (multiplier of 7.7x matches observed frequency in demodulation spectra (multiplier of 7.7 times).

SAE 863 Material bearings,Mil-B-5687C Sintered Iron - Copper oil impregnation bushing, self-lubricated bush.

Bearingdamage types

But, before going any further I would like to share with you what was I told some time ago: “Conducting vibration analysis in order to determine bearing condition should not be done for the purpose of “do I need to replace the bearing immediately”, but to assess bearing integrity and ability of the bearing to reliably perform its function. No bearing is designed to produce visible fault frequency if operates normally and is in good condition.”

This TKBA40-CA is a replacement toolcase with inlay for the SKF TKBA40 belt alignment tool.

The average price of a 2014 Jeep Cherokee wheel bearing replacement can vary depending on location. Get a free detailed estimate for a wheel bearing ...

After band pass filtering, we rectified the signal, so it is all positive which helps to further highlight the impacts. This is shown on the screen below.

Next step is to mark the measurement points. You can create a simple sketch of the machine or work from the machine photo like in the example below. This is not a necessary step and more experienced users will go directly to creating those points. Nevertheless, we do recommend it as it is much better for yourself to make sure entire equipment is covered as well when communicating with the person taking the measurements — visualisation helps.

Nov 1, 2022 — I've been using John Deere Polyurea synthetic grease in wheel bearings, and many other applications for 25 years or so. Never had any problems, ...

This post provides a detailed examination of the detection, location, and diagnosis of faults in a locomotive alternator using vibration analysis. Health of the alternator, or any rotating machine for that matter, can be assessed by collecting and analysing vibration data. Vibration provides a valuable insight that if timely actioned can prevent unscheduled breakdowns and or costly repairs.

We can see that bearing inner race defect frequency is visible in velocity indicating that damage more advanced. This confirms our diagnosis and also helps to make final conclusion — change the bearing if you want reliable operation.

If we know bearing designation or bearing dimensions including the number of balls / rollers, we can calculate expected bearing fault frequencies.

Before taking the measurements, we should take time and gain an understanding of the equipment we will be measuring. For example, recognising dominant forcing frequencies is important as those will assist us with analysis and diagnostics at later stage. Below are listed some of those frequencies and associated root causes:

In this case, from acceleration and demodulation analysis, we conclude that there is a strong possibility of bearing inner race deterioration.

We move on and then use demodulation to determine the rate of knocking. Demodulation will help us to better understand the impact rate so we can determine what may be causing these impacts. It is calculated from acceleration signal with some data processing.

8613869596835

8613869596835