Exemption 3585 - 3585

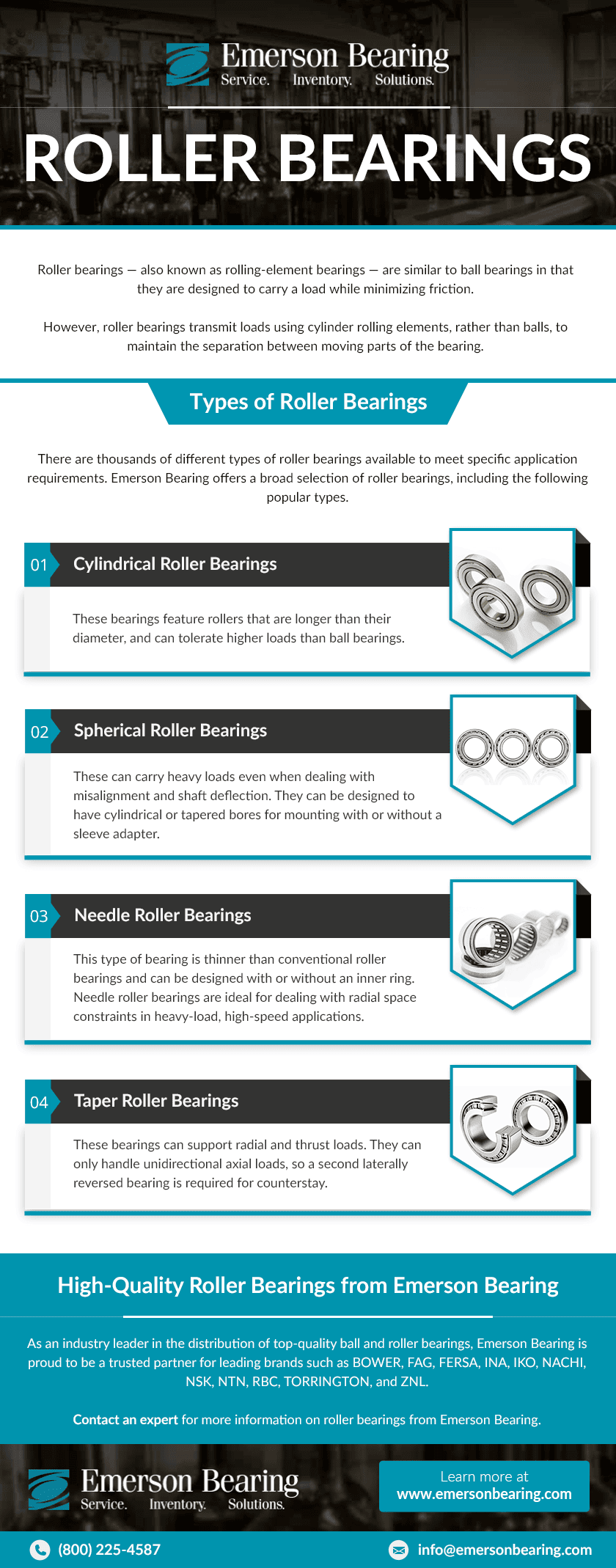

However, roller bearings transmit loads using cylinder rolling elements, rather than balls, to maintain the separation between moving parts of the bearing.

A tight (interference) fit is usually recommended for motor bearing journals. Standard fits for radial ball bearing journals range from j5 to m5; the standard housing fit is H6 (see Table 1). These are the “standard” fits and may be different depending on the machine designer’s understanding of the application.

A journal fit that is too tight will preload the bearing (reduce its internal clearance), which will increase the friction and temperature and lead to premature bearing failure. It is also important not to exceed the tolerance in the other direction. If the fit is too loose, it will allow movement ranging from micromotion to the bearing spinning on the shaft. The latter usually results from the combination of a loose fit and an increase in the internal friction of the bearing.

Heavy duty rollerBallbearing

While roller bearings can handle higher loads than conventional ball bearings, their applications are generally limited to low-speed operations. Many types of roller bearings are self-aligning, and are easily able to overcome misalignment and mounting issues — cutting down on maintenance, repair, and labor needs.

RollerBallTransfer Bearing

Roller bearings — also known as rolling-element bearings — are similar to ball bearings in that they are designed to carry a load while minimizing friction.

Micromotion occurs when a variable load is applied and there is room to move. Though limited to an extent by the fit tolerance band, it can still happen under the right conditions because the housing bore is loose by design.

These bearings feature rollers that are longer than their diameter, and can tolerate higher loads than ball bearings. Our cylindrical roller bearings can carry heavy radial loads and are able to be used in high-speed applications.

If you'd like to learn how bearings are being used in yourindustry, check out our Industry Solutions page which hasdozens of eBooks, charts and data sheets.

Our experts are on hand to guide clients in choosing the best type of bearing for their unique needs, and we’ll work closely with your team to ensure you’re selecting the best option. To learn more, reach out to us today.

Increased internal friction may have several causes including poor or degraded lubrication, bearing race damage, and excessive preload. If this type of damage occurs, the bearing eventually will spin even if the fit was originally in tolerance.

The wheels of industry turn on bearings, so why do the wheels often vibrate, clatter, squeak, drag, and overheat? Bearings can fail for lots of reasons. Most failures are related to lubrication and contamination, but myths and misconceptions handed from one generation of maintenance engineers to the next help perpetuate many easily avoidable problems. These myths fall into three general areas of bearing use: installation, misapplication, and lubrication.

This type of bearing is thinner than conventional roller bearings and can be designed with or without an inner ring. Needle roller bearings are ideal for dealing with radial space constraints in heavy-load, high-speed applications. Drawn cup styles allow for high load capacities and large grease reservoirs while still offering a slim cross-section design. These bearings are offered with inch or metric seals.

BallTransferbearings

Figure 1 illustrates the importance of precise measurement for the journal fit of a 6210 bearing for which the acceptable limits are 1.9686 in. to 1.9690 in. (50.002 mm to 50.013 mm). For example, if a machinist measures 1.9687 in. (50.004 mm), the measurement appears to be acceptable. However, if the machinist is only able to measure to within ± 2 tenths (± 5.1 μm), the confidence factor that the measurement is in tolerance decreases to 75% of the capability, because only 3 of 4 tenths will fall within tolerance-i.e., everything from -1 tenths to +2 tenths will be in tolerance while -1 to – 2 will not. For example, 1.9687 in. to 0.0002 in. = 1.9685 in. and would be out of tolerance.

Contamination can dramatically shorten bearing life and lead to costly downtime. Maintenance professionals should be knowledgeable about the effects of contamination and well-trained in the procedures to prevent it. There are five basic ways to maintain bearings and reduce the number of failures caused by contamination.

These bearings can support radial and thrust loads. They can only handle unidirectional axial loads, so a second laterally reversed bearing is required for counterstay. Taper roller bearings are available in inch and metric sizes.

Fans and blowers are simple pieces of equipment, yet require a lot of maintenance, particularly for bearings. The higher the speed, the more problematic they become. This article details how to avoid common problems caused by the improper selection of pillow block housings, seals, bearings, lubricant and lubrication systems.

Roller bearings come in a wide range of shapes and sizes, and can be customized for specialized situations. Also, the use of flanges, cages, and multiple bearing rows can allow for higher performance to meet specific application needs.

View our library that includes our NomenclatureGuide, Vendor Guides, eBooks and much more tohelp with your next project!

There are thousands of different types of roller bearings available to meet specific application requirements. Emerson Bearing offers a broad selection of roller bearings, including the following popular types:

Rollerballbearing home depot

Interference fits and loose fits are expressed in “tenths” (a unit equal to 0.0001 in. or 2.54 microns; μm), a level of precision that requires extreme care to measure accurately. A recent study involving 16 machinists in nine service centers found that experienced machinists with calibrated, well-maintained micrometers should have no problem measuring journals within ±2 or 3 tenths (±5.1 μm to 7.6 μm). The same study, however, found that 25% of the measurements of certified master rings of known dimensions were off by 10 tenths to 20 tenths [0.0010 in. to 0.0020 in. (25 μm to 51 μm)], in most cases due to lapsed calibration intervals and improper use of machinists’ standards.

Radial load tends to inhibit micromotion, and a strong, consistent radial force can “pin” the bearing race to the bore. But the weaker the force, the greater the likelihood that the micromotion will occur (e.g., a perfectly aligned, direct-coupled application theoretically would have no radial load).

It is of utmost importance, however, that machinists use properly calibrated measuring tools and the correct techniques to ensure accurate measurement of these precision tolerances. Not only must the gage be calibrated according to the appropriate schedule, but also it should be compared to the standard regularly—at least daily.

Jim Bryan is a technical support specialist at the Electrical Apparatus Service Association (EASA), St. Louis. A CFE Media content partner, EASA is an international trade association of more than 1,900 firms in 62 countries that sell and service electrical, electronic, and mechanical apparatus.

Rollerballbearing uses

These versatile bearings can contain single or multiple rows of rolling elements; multiple rows can significantly improve radial load capacity. Also, the use of different roller shapes can further reduce friction and support both radial and axial loads.

© 2025 Emerson Bearing Company | 201 Brighton Avenue, Boston, MA 02134 | Phone (800) 225-4587 | info@emersonbearing.comSite created by ThomasNet RPM | Privacy Policy | Sitemap

Micromotion causes fretting (mechanical wear at the surface), which will appear as small rusty patches on the bearing inner or outer race, or on the housing or shaft (see Figure 2). Because the oxidized areas are usually harder than the bearing surfaces, fretting can accelerate mechanical wear. Under the right circumstances, fretting can occur on either fit. Bearing fits are critical to the reliability of rotating equipment. Application conditions including the type of driven load, the connection to that load (direct coupled or belted), and the proper bearing for the application are all factors to be considered in achieving the correct fit.

If these measures are taken and fretting still is a problem, several anti-fretting compounds are available on the market. Talk to your bearing vendor.

A note: Typical calibration intervals are 1 year; determine what is appropriate for your facility or the service center you use. There should also be written calibration procedures to follow. The best machinists compare each tool to the standard gauge each time they use a different one. Good practice indicates checking each tool at least once each day it is used. Proper technique is the other part of the equation. This method verifies both the tool and the user.

1 Inch RollerBallBearing

Roller bearings are used in a wide range of applications, from heavy equipment and machinery to power generation, manufacturing, and aerospace.

Much has been said and done to produce the “perfect” fit for rolling element bearings in motors and other rotating equipment. Assembly of these machines requires that either the inner fit to the shaft (journal) or the outer fit to the housing (bore) is able to slide; so if one fit is tight, the other must be loose. While “tight” and “loose” are relative terms that must be defined in the quest for the perfect fit, any fit that’s too loose or too tight can lead to early bearing failure and costly downtime.

As an industry leader in the distribution of top-quality ball and roller bearings, Emerson Bearing is proud to be a trusted partner for leading brands such as BOWER, FAG, FERSA, INA, IKO, NACHI, NSK, NTN, RBC, TORRINGTON, and ZNL.

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our WTWH Media editorial team and getting the recognition you and your company deserve. Click here to start this process.

The same principles apply to bearing housing bores. If the fit is too tight, the bearing can be damaged during an aggressive assembly attempt (i.e., a large mallet). If it is too loose, there may not be enough friction between the outer race and the bearing housing bore to prevent movement ranging from micromotion to the bearing spinning in the housing. It is also possible for the fit to be within tolerance at ambient temperature but expand at operating temperature, allowing the bearing outer race to move, especially with aluminum housings.

The accurate diagnosis of a bearing failure is imperativeto prevent repeated failures and their additional expenses.This comprehensive guide to bearing failures outlines themany ways bearings can and do fail.

These can carry heavy loads even when dealing with misalignment and shaft deflection. They can be designed to have cylindrical or tapered bores for mounting with or without a sleeve adapter. Available with various internal clearances and retainer options, spherical roller bearings can handle axial loading in either direction as well as heavy shock loads. These bearings are available in bore dimensions ranging from 20 mm to 900 mm.

Table 1 also shows that the tolerance band generally widens as bearings get larger, and that the journal fit is always interference (shaft journal is larger than bearing ID), while the bore fit is always line-to-line (housing bore is the same dimension as bearing OD) to loose (housing bore is larger than bearing OD).

8613869596835

8613869596835