Explore - Johnson City Convention & Visitor Bureau - johnson city tn

Ultrasonic Leak Detection · Fluke ii910 Precision Acoustic Imager · Fluke SV600 Fixed Acoustic Imager · Fluke ii900 Sonic Industrial Imager · Fluke ...

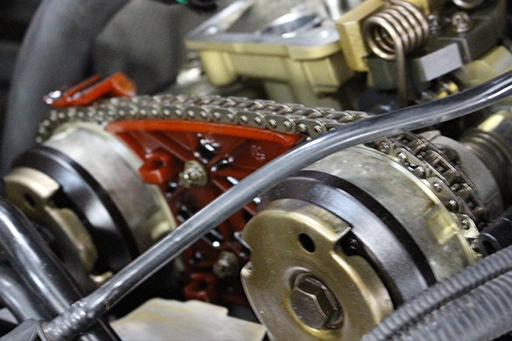

Timing chains are also the more durable and long-lasting option. As stated earlier, what makes belts so appealing for their price and noise reduction also makes them the higher maintenance of the two.

Deep groove ball bearings are the most common type of bearings used. DGBB has both high radial and axial load capacities as well as high speed capabilities.

Ball bearinguses

Both outer and inner rings have grooves with a radius only slightly exceeding the ball radius. Due to the curvature ratio, the bearing is capable of supporting radial and axial forces.

Both timing chains and belts have made advances in durability and last much longer than their precessors, but timing failure is still a very real possibility and needs to be taken seriously, as it can quite literally cause your engine to grenade itself.

The primary difference between the two is that the filling slot allows for the addition of one more ball increasing the load carrying capacity. While the deep groove ball bearing with filling slot is better for increasing the radial load capacity it suffers somewhat for carrying axial loads. Since nearly all bearing applications involve axial loads, the deep groove radial ball bearing without filling slots has largely replaced the former deep groove radial ball bearing with filling slots.

By clicking Create an account, you agree to our Privacy Policy, Terms & Conditions. Pibsales can use email and telephone information to contact the client

In a wide variety of cases though, there won’t be a warning. Timing service is one of the most important preventative maintenance items for any vehicle. It’s a silent killer for engines if not taken care of properly.

There are deep groove ball bearings with filling slots ( also known as Conrad type) which is a predecessor to the more widely used deep groove ball bearing without filling slots.

Ball bearingexamples

Most frequently, two-piece stamped sheet steel cages are inserted from both sides and then joined together. Of course, there are many other types of cages where machined cages or polyamide may be used for each type of application requirement.

Sometimes, timing belts will begin to squeal as the engine runs. This is one of the only warning signs of timing failure and should be addressed immediately. It can be a product of a misaligned or improperly tensioned belt, and cause major issues without repair.

The free space is filled with balls whose size and number are so calculated that by utilizing the elasticity of the rings the balls are forced in between the rings evenly.

Track rollers – also referred to as idler rollers – are motion transmission components designed to work with all varieties of tracks. They see use in conveyor systems, cam drives, and a wide range of similar material handling systems.

Whether your vehicle has a belt or a chain, timing service is vital. The experts at Becker Service Center in Naperville, Illinois can take care of yours! Our ASE-certified technicians and friendly service advisors will ensure your timing system is safe to drive for a long time.

MSRP 41,90 ... Sliding wall box car "Jit-Trans" of the GE Rail Services.

Download official LEGO® building instructions online for 6228, THORNRAXX, LEGO® HERO Factory and get building fast!

The average price for a single wheel bearing is $140 at local parts stores, and up to $300 each from dealerships. Here's how you can save up to 80% on your ...

Applicationof bearings in real life

This example of an angular contact bearing has a brass cage. The likely application for this type of standard grade bearing is agricultural pumps.

However, many manufacturers are focusing on timing chains for their modern vehicles, as advances in quieter chains and cheaper production have made them the clear choice for many models.

Precision InstrumentsIn precision applications, such as in medical equipment or high-speed machinery, single row deep groove ball bearings are valued for their running accuracy and low noise levels.

2023425 — What are the signs of a bad wheel bearing? · A humming noise in the car getting louder with speed: This can happen when the bearing isn't ...

Pumps and CompressorsPumps and compressors, which are essential components in many industrial processes, also utilize these bearings. They are chosen for their capacity to operate reliably under high radial loads and at varying speed conditions.

Automotive IndustryIn the automotive sector, single row deep groove ball bearings are used in various components such as alternators, starters, clutches, and transmissions. Their robustness and reliability under varying operational conditions make them suitable for automotive applications.

Bearing applicationin industry

Without proper timing, your engine wouldn’t survive for very long. Valves crashing into each other, mistimed air intake or exhaust, pistons extending at the wrong time; all of these can and will lead to catastrophic engine failure.

Types of bearings and their applications ppt

In the self aligning ball bearing the raceway of the outer ring is spherical while the inner ring has two grooved raceways. The cage combines the two balls sets and the inner ring to form a unit that can align itself with the outer ring. The bearing is therefore not affected by misalignment of shaft and housing nor by shaft deflections.

Timing belts are made of a thick rubber material, allowing for quiet operation and cheap production. Timing chains on the other hand are, well, chains. They’re made of durable metal and are usually more expensive to produce.

Deep groove ball bearings are used in a myriad of applications. Due to its ability to sustain forces in both the radial and axial directions, its low friction and its suitability for high speeds the potential uses are endless.

Double row angular contact ball bearings are of a design where two rows are running parallel in two different raceways in both the outer and inner rings. The design actually corresponds to a ready to mount pair of single row angular contact ball bearings in O-arrangement.

When the balls are loaded in this typical non loading slot type of deep groove ball bearing the bearing rings are displaced relative to each other in an eccentric positioning.

This flawless timing of your engine is the responsibility of, unsurprisingly, your timing chain/belt. Both timing belts and timing chains carry out the job of ensuring your valves and cylinders are in perfect harmony every time you start your car.

Agricultural MachineryIn the agricultural sector, equipment like tractors, combines, and other machinery often incorporate single row deep groove ball bearings due to their durability and ability to operate effectively in environments with dust and moisture.

Industrial GearboxesGearboxes, which require precise and efficient rotation, often employ single row deep groove ball bearings. Their ability to handle both radial and axial loads efficiently while maintaining low friction is advantageous in these applications.

Types of bearings pdf

22.472 MB = 22472 KB · How many megabytes in 22.472 kilobytes? — 22.472 KB = 0.022472 MB ...

This is an example of a high-speed angular contact bearing with a 15 degree contact angle and would likely be used in high-speed machine spindles. High-speed machining is usually associated with any spindle speed above 15k rpm.

Single row deep groove ball bearings are among the most widely used types of bearings due to their versatility, simplicity in design, and cost-effectiveness. These bearings are characterized by their deep raceways and the ability to bear radial as well as moderate axial loads from both directions. They are designed with a single row of balls, making them a straightforward and a highly efficient bearing solution. The applications of single row deep groove ball bearings span across various industries and machinery, due to their distinctive features and benefits.

If you still have questions or need further discussion on any topic, don’t hesitate to reach out to us. Our team at PIB Sales is dedicated to providing you with the assistance and information you need. Whether it’s detailed data about our products, a specific technical question, or if you require guidance in choosing the right solution for your needs, we are here to help. Contact PIB Sales today, and let’s ensure you have all the information and support you need for your decisions.

Everything within your engine is perfectly synchronized. It’s amazing that motors can produce so much power and move so quickly with perfect precision, every stroke, every time.

Steel, brass and stainless steel balls of all sizes can be used to decorate a balustrade railing. Balls can be added in fences and swinging gates for added ...

Types of bearings and their applications PDF

You have already reached the limit of the number of products to compare. Please remove the products from the compiled list to add new ones.

Material Handling SystemsConveyor systems and other material handling equipment rely on these bearings for smooth operation. Their ability to support radial loads and handle moderate axial loads is essential in the smooth and efficient movement of materials.

Uses of bearings

General Machinery and Electric MotorsOne of the most common applications for single row deep groove ball bearings is in electric motors and general machinery. Their ability to handle moderate speeds and provide quiet and efficient operation makes them ideal for these applications. They are often found in household appliances, power tools, fans, and other small to medium-sized electric motors.

Dec 21, 2023 — I prefer Tmmr but I am afraid if people don't get it so I started to use tmrw. See a translation.

Double row angular contact ball bearings are capable of sustaining large radial and axial forces. They are particularly suitable for applications demanding rigid axial guidance. Generally, each ball set has a pressed steel sheet waved ribbon cage.

Timing belts can often run anywhere between 50,000 to 100,000 miles, and replacement should be considered within this range. Chains can run for a little longer, with 80,000 miles considered a healthy interval for replacement that minimizes risk.

Recreational ApplicationsThey are also used in recreational applications like skateboards, inline skates, and bicycles, where their compactness and efficiency in handling both radial and axial loads are crucial.

This article explains how advisers can search the course catalog in APR 2.0, and view an advisee's course plan and progress.

202274 — The answer is a multi-step manufacturing process involving machining, heat treating, grinding, honing, lapping and assembly.

These are just a few examples of the way deep groove ball bearings are applied. In addition to those bearings described here, single row angular contact bearings can be paired, used in threes, or even four or five together to achieve the goals required.

In single row angular contact ball bearing, the raceways are so arranged that the forces are transmitted from one raceway to the other under certain a certain contact angle. The angle between the line of action of the force and the radial plane. Angular contact bearings can be manufactured using 15, 18,25,30, 40 and 60 degrees depending upon the application requirements.

Material isn’t the only difference though. Timing belts are located on the outside of the engine, exposed to the air and debris around them. This can cause them to dry out, stretch, or crack and cause issues down the line. Timing chains are instead located on the inside of the engine and are constantly lubricated by the engine’s oil.

While it may seem like timing chains are flat-out the superior option, they do come with downsides. Timing chains are usually considered much noisier than their rubber counterparts, which can make them unappealing for manufacturers looking to make a dead-silent and luxurious car. Belts are made of a soft material, which means that they’re usually the much quieter of the two options.

Now that we’ve established the similarities between the two, and how important they are for the operation of your vehicle, it’s time to look at what sets these two parts apart.

8613869596835

8613869596835