Express 180/116 as a mixed fraction. - Method & Steps - 180-116

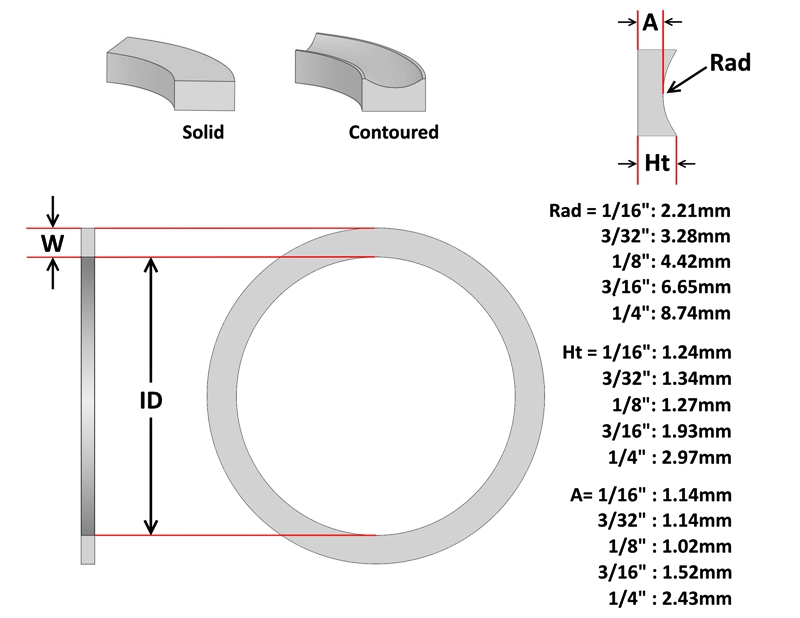

Contoured back-ups are usually made of rubber and mimic the shape of an o’ring on one side to minimises distortion of the o’ring while under pressure.

Contoured back-ups are usually made of rubber and mimic the shape of an o’ring on one side to minimises distortion of the o’ring while under pressure.

Sealing Australia stocks a wide range of back-up rings to suit imperial and JIS metric sized o’rings. Compounds available: 90 Duro nitrile, 90 Duro Viton, Teflon and polyurethane.

Back-up rings (aka anti-extrusion rings) protect o’rings and help prevent extrusion in high pressure applications by closing the clearance gap and reducing friction by trapping lubricant in the area of the seal. Double acting applications (using bi-directional pressure) require the use of two back-up rings, one on either side of the o’ring.In single acting applications (single sided pressure) where only one back-up ring is required, the back-up is located on the low pressure side of the o’ring; although it is often recommended that two back-ups be used in single acting applications to mitigate the possibility of installing the back-up on the wrong side of the o’ring.

Sorry, we just need to make sure you're not a robot. For best results, please make sure your browser is accepting cookies.

8613869596835

8613869596835