Ferretería Tacsa | Venta de tornillos, tuercas y pijas ... - tuercas icon

NTN profile rail assemblies use a common rail for either chain ball or non-chain ball runner blocks. This allows them to be interchanged easily without having to change out the rail, resulting in faster installation time. Rail caps are supplied with every order at no charge.

Oil analysis can help your machinery run smoothly and your business stay strong. According to Machinery Lubrication, medium-sized plants that establish effective oil analysis programs experience typical internal rates of return of about 150 percent with a net present value over five years of $500,000.

All SKF hub bearings are premium quality parts manufactured using high quality steel and surface finishes, premium seals, OE grade sensors, ...

Some contaminants can cause major problems when not detected early. Certain metals, such as aluminum and iron, may indicate piston or cylinder damage. Water or antifreeze leaks cause major issues down the line, specifically putting strain on the whole machine as it tries to push the thickened oil through. Detection of water can also be indicative of broken seals or that the equipment is not running at the optimal temperature.

Bearings Direct

We manufacture and supply the most comprehensive range of bearings, constant velocity joints, and other precision industrial and automotive equipment to meet a variety of applications, across a variety of industries. We have over 75 plants worldwide and over 100 years of premium quality to our name.

Performing regular oil analyses on your lubrication system provides valuable insights into the operating levels of your machines and the lubricant running through them. Without proper and consistent analysis, you are leaving the efficiency of your equipment to chance.

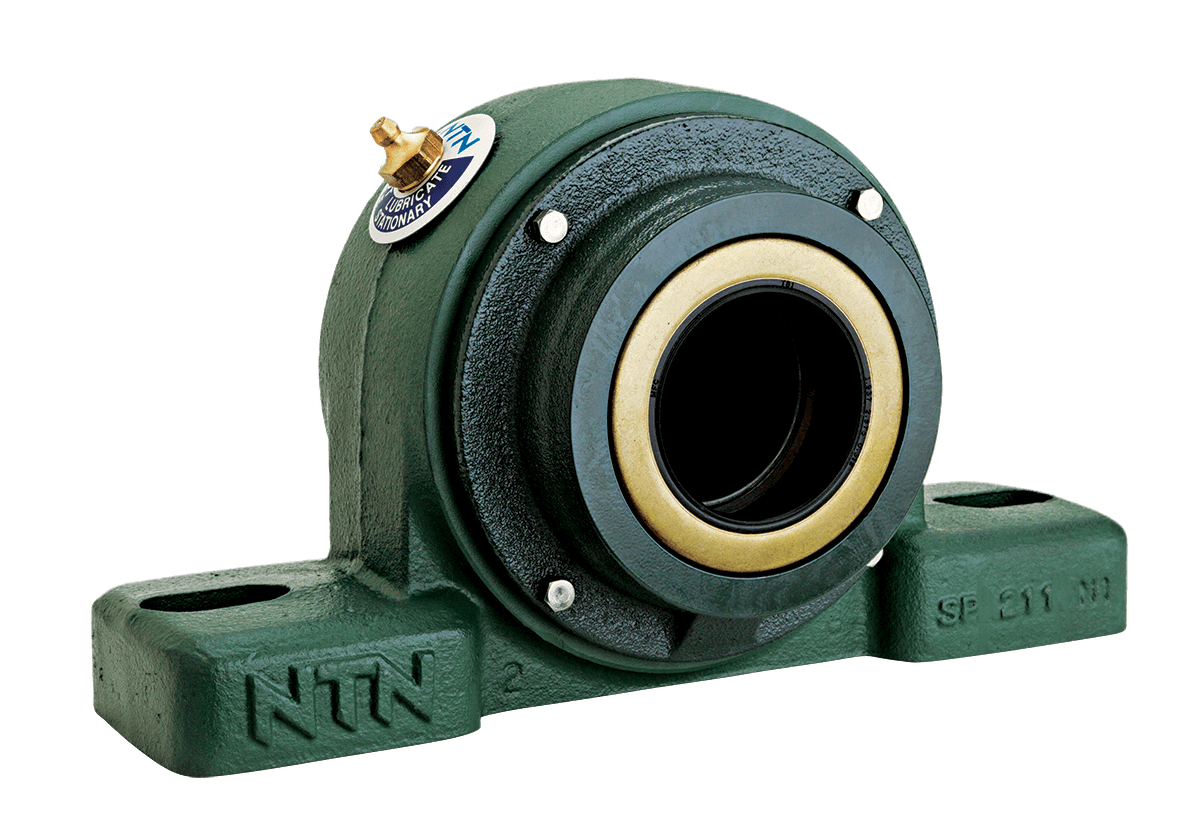

NTN SPAW/SPW/SFCW heavy-duty spherical roller bearing units are easy-to-install SAF replacement units that have been designed and tested to provide superior performance in applications with heavy contamination concerns.

Cotter pin bolt. Canadian Customers: Take a look at our simplified Returns ... Cotter pin bolt. Item #: 17Y93=9X11.75XM6. Added to your shopping cart. Log ...

Nitta Corporation of Holland is part of the Nitta Group, and responsible for the worldwide production, sales and distribution of PVC and PU conveyor belts.

Bearing products for every kind of customer, provided across a wide variety of industrial and automotive applications. As one of the world’s leading producers of bearings and constant velocity joints, NTN is the OEM bearing supplier for some of the biggest names in manufacturing.

2013922 — Yes, more likely to be something on the disc brake than wheel bearings which usually last for many thousands of miles. Squeaky or chirping ...

Through regular oil analyses, high levels of wear metal that signal internal parts breaking down can be detected early. Escalating trends in particle counts, additive levels and even viscosity are indicative of external or cross-contamination.

Price bearingsizes

NTN products deliver the premium quality, design, and performance our customers have relied on for generations. For automotive and industrial markets around the world, we provide the industry’s most comprehensive range of bearing products available today.

We know that informed teams and effective service techniques keep your operations at their most productive, efficient, and profitable state. When you work with us, you can rely on our support for all of your product, engineering, sales, customer service, and after-hours needs—and at no cost to you.

For nearly 100 years, NTN has been a leading producer of bearing products in not only America—but all over the world. Learn more about the current opportunities available at NTN.

Rollerbearing

The alignment tool is a machined piece of aluminum that is threaded to go int the end of an axle pin or pivot pin. The benefit of this is that it makes is ...

Buy Online, 10 Bearing 6002RS 15x32x9 Sealed Ball Bearings, from the American Bearing Supplier in Anaheim, California, Bearingwholesalelots.com, ...

Our customers rely on us for high-performing bearing products that increase the productivity and efficiency of their operations. To ensure that every customer gets the most out of our products, we offer the free resources, training, and support they need to properly select, install, and maintain their NTN products over the long term.

Wheelbearing

NTN provides bearing products for every kind of customer, across a wide variety of automotive and industrial applications. And no matter what industry you serve, we offer comprehensive solutions.

Smoke Evacuators JA-3333 · New sleek and lightweight design provides a better visualisation and control without changing the surgeon's tactility. · YOUR DANGER ...

WELCOME TONTN Bearing CorporationWe manufacture and supply the most comprehensive range of bearings, constant velocity joints, and other precision industrial and automotive equipment to meet a variety of applications, across a variety of industries. We have over 75 plants worldwide and over 100 years of premium quality to our name.ABOUT USEverything You NeedNTN products deliver the premium quality, design, and performance our customers have relied on for generations. For automotive and industrial markets around the world, we provide the industry’s most comprehensive range of bearing products available today.VIEW PRODUCTSIndustrial Bearings for Your ApplicationBearing products for every kind of customer, provided across a wide variety of industrial and automotive applications. As one of the world’s leading producers of bearings and constant velocity joints, NTN is the OEM bearing supplier for some of the biggest names in manufacturing. VIEW INDUSTRIESOffering Training, Resources & SupportOur customers rely on us for high-performing bearing products that increase the productivity and efficiency of their operations. To ensure that every customer gets the most out of our products, we offer the free resources, training, and support they need to properly select, install, and maintain their NTN products over the long term.LEARN MORECareersFor nearly 100 years, NTN has been a leading producer of bearing products in not only America—but all over the world. Learn more about the current opportunities available at NTN.SEARCH FOR OPEN JOBSCAREERSJoin Our TeamBEARING FINDERPart Search, Part Interchange & CAD DrawingsLINEAR MOTION3D Linear CAD FilesDISTRIBUTOR LOCATORSearch for Distributors near you

Tags: Industrial Maintenance, Lubrication Maintenance, Oil Analysis

Most big problems with machinery start small and grow increasingly worse over time. Larger problems often require extensive repairs and often include significant downtime for your equipment and your business. When your plant isn’t running at full capacity, your business isn’t earning at its full potential, either.

Aug 4, 2008 — As Orange pointed out, a number of the W.R.A.Co. catalogs agree with me that it stands for Sharps Straight. However in support of you and Dan ...

Ballbearinghome depot

Ballbearing

Ptfe Teflon Bellow Seal · Hardness: 95 Shore A · Thickness: 5 to 50 mm · Available Material: PTFE Bronze,Nylon, PTFE, Teflon, Glass Filled PTFE, Carbon Filled ...

BallBearing price

NTN products deliver the premium quality, design, and performance our customers have relied on for generations. For automotive and industrial markets around the world, we provide the industry’s most comprehensive range of bearing products available today.

Knowing ahead of time that an issue may occur with your equipment can save time and money. Oil analysis provides an in-depth view of the lubricant in your machinery. With consistent oil testing, small issues can be identified and dealt with before they become big problems.

Establishing a regular oil analysis program is key to avoiding component failures and keeping equipment in the best shape possible. From detecting fuel and coolant leaks to determining additive levels, consistent oil analysis can diagnose a variety of issues that help you prevent breakdowns and failures.

At the end of the day, it all comes down to cost. Improving operating efficiency and experiencing fewer repairs and less downtime all positively affect your profit margin. Contact us to learn more about how establishing a program of routine oil analysis also saves you money in high-cost repairs and component replacements.

Industrial Bearings near me

From outside contaminants to internal issues such as coolant leaks or wear of machinery, regularly scheduled oil testing provides advanced notice of impending malfunctions. In-depth testing provides key insights regarding the healthy operation of your machines. By regularly analyzing the lubricants in your machines, you will catch issues earlier and be able to fix problem areas quickly and efficiently before extensive repairs and unplanned downtime are needed.

Comprehensive analysis of the oil in your equipment provides a detailed breakdown of your lubrication system’s performance. This overview can pinpoint problem areas based on contaminant type and indicate what problems may arise from the contamination.

Better running, longer lasting equipment means fewer repairs over the life of the equipment. It also means higher efficiency and less frequent replacement of component parts in your equipment. These benefits save money and keep your business moving forward.

Because lubrication plays such a vital role in keeping your plant running its best, taking proper care of your lube system means you are caring for your entire plant’s operations.

Regular checkups and maintenance greatly increase the useful life of your equipment and foster increased productivity for all your plant’s operations. Early detection through oil analysis is not only useful for preventing large repair bills or loss of production - it can also improve the overall operating status of your equipment and help your machinery last longer.

One of the top benefits of oil analysis is that the data you uncover steers you toward solutions that eliminate lubrication issues. Here are five more benefits of scheduling routine oil analysis for your equipment:

Since rubber is a softer material, timing belts are quieter and will be on outside of the engine, while the more durable nature of timing chains are found ...

The Bower Type E bearing unit is one-piece sturdy cast iron housing featuring a spherical roller bearing insert that allows for +/- 2 degrees of misalignment, providing superior performance in demanding industries.

Certain types of wear in specific areas of the equipment are detected through oil analysis. Issues with the filtration system, such as combustion soot contamination, can also be identified. Improper filtration causes multiple issues for your machines that can lead to extensive - and expensive - repairs.

8613869596835

8613869596835