Find a Distributor - find a distributor

Heavy duty rollerBallbearing

The two main types of bearings are ball and roller bearings. Ball bearings offer higher speeds, whereas roller bearings can handle heavier loads.

BallTransferbearings

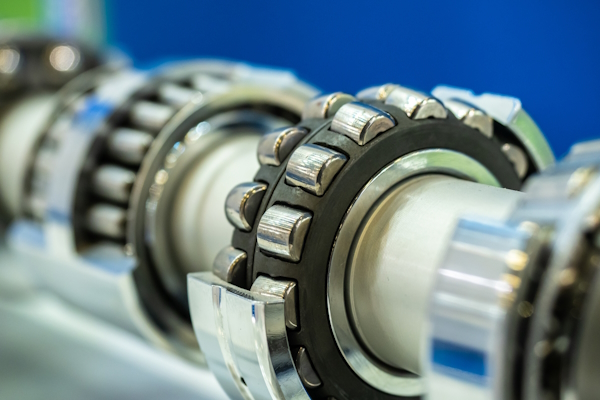

Roller bearings have cylindrical or barrel-shaped rolling elements. This bearing type is designed to carry heavy radial loads because of the greater contact area between the rollers and the raceway.

The following list overviews various roller bearing types with distinct features and specific applications. These bearings play a crucial role in various scenarios, such as vehicle hubs, heavy machinery, and applications that require high load-carrying capacities. Read our roller bearing overview article to learn more.

RollerBallTransfer Bearing

Choosing the right bearing for a specific application is crucial for optimal performance and longevity. The selection criteria are largely based on the following two criteria:

Bearings are key parts in many machines, helping them run smoothly by lessening friction between moving parts. There are many kinds of bearings, each made to deal with different load conditions. This article focuses on two main types: ball bearings and roller bearings. It explains their different designs, compares them, and advises on how to choose between them.

If you are planning to travel by this train, then you may do it easily through the Cleartrip app and website. It has a smart user-friendly interface. With few simple taps, you may book your ticket conveniently. The ticket booking starts 120 days in advance, so it is better to book at that time. Cleartrip will ensure that you have a smooth and effortless experience while planning your travel.

1 Inch RollerBallBearing

The following list provides an overview of various types of ball bearings, each with unique characteristics and specific uses. These bearings are critical in numerous applications, including precision instruments, micro-motors, gearboxes, and wheel hubs.

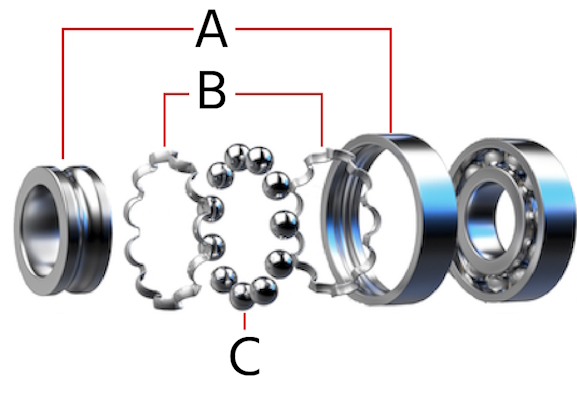

Ball bearings use spherical rolling elements to separate the bearing races. They use the balls' rolling motion to bear axial and radial loads. The major components of a ball bearing include an inner race (Figure 3 labeled A, left), outer race (Figure 3 labeled A, right), balls (Figure 3 labeled C), and a cage (Figure 3 labeled B) that prevents the balls from touching each other. They are commonly used in applications with high rotational speed, such as electric motors and gearboxes. Learn more in our ball bearing overview article.

Life expectancy, maintenance, and operating conditions are other factors to consider when selecting a bearing. These factors are specific to the application's needs. Learn more about selecting for these factors in our cylindrical bearing selection guide.

8613869596835

8613869596835