Flight AA910 / AAL910 - American Airlines - aa 910

Lincolnlubricationwebsite

Lincoln Industrialdistributors

SCED 4004 - Elementary Science Teaching (3 Credits). This course explores issues in elementary school science learning and teaching.

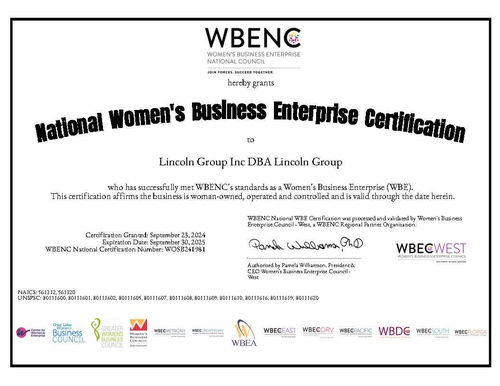

Categories StaffingEmployment Services 722 E. Main Street, Ste. 105 Santa Maria CA 93454 (805) 457-5396 Send Email lincolngrp.com Hours: Monday- Friday 8am to 5pm Driving Directions: located in the La Brea Plaza Shopping Center on E. Main St. in Santa Maria ,CA About Us Lincoln Group was founded on May 12, 2020, and is a 100% Woman-Owned Firm specializing in Highly Customized Executive Search and Professional Interim Staffing Solutions. We believe that your staffing needs are as unique as your organization and should be treated accordingly. Our high-touch, fully customized approach is distinct, and personal, and links you to hiring success. Our customers love this elite level of service.We offer a full suite of staffing services to create a tailor-made experience for your hiring needs, be they in retained search, executive search, direct hire, interim professional staffing, or light industrial staffing. Our professional areas of expertise include accounting & finance, human resources, marketing, technology, and legal.Lincoln Group Industrial Services LLC is a subsidiary of Lincoln Group, that specializes in placing temporary, seasonal, contract, and contract-to-hire staff in facilities, maintenance, warehouse, production, distribution, logistics, agriculture, hospitality, entertainment, and construction management. The biggest differentiator in our firm compared to others is our staffing expertise and that we care about every single associate who works for us and our clients. We aim to make your experience as seamless as possible. Our mission is to ensure that our employees and your hiring managers have a memorable experience with each engagement. Highlights StaffingRecruitingIndustrialProfessionalMedical Images Gallery Image LGI_Logo.jpg × Gallery Image Lincoln_QR_Code_FINAL.png × Gallery Image Lincoln_with_blue_industrial.jpg × Gallery Image Lincoln%20Group%20WOSB%20Certificate.jpg × Gallery Image Lincoln%20Group%20WBE%20Certificate.jpg × Rep/Contact Info View Personal Bio Monica Gauna × Hello, my name is Monica Gauna, Branch Manager for Lincoln Group in Santa Maria. I have worked in the Staffing Industry for over 24 years. I enjoy working with the community and the entire Central Coast. I look forward to the opportunity to service you! Close Monica Gauna Branch Manager Phone: (805) 457-5396 Send an Email 722 E. Main St, Suite 105 Santa Maria, California CA 93454 Share × Print Email Facebook Twitter LinkedIn Pinterest Close Tell a Friend × Send RequestCancel

What about the brakes? A caliper that is sticking, or a brake pad that is loose and dragging, may make a metallic scraping noise as it rubs against the brake rotor or dust shield. The frequency of the noise will also change proportional to vehicle speed, but will often go away or change when the brakes are lightly applied. Noise that occurs only when the driver is braking likely is a brake problem such as worn pads and not a bad wheel bearing.

Lincoln Group was founded on May 12, 2020, and is a 100% Woman-Owned Firm specializing in Highly Customized Executive Search and Professional Interim Staffing Solutions. We believe that your staffing needs are as unique as your organization and should be treated accordingly. Our high-touch, fully customized approach is distinct, and personal, and links you to hiring success. Our customers love this elite level of service.We offer a full suite of staffing services to create a tailor-made experience for your hiring needs, be they in retained search, executive search, direct hire, interim professional staffing, or light industrial staffing. Our professional areas of expertise include accounting & finance, human resources, marketing, technology, and legal.Lincoln Group Industrial Services LLC is a subsidiary of Lincoln Group, that specializes in placing temporary, seasonal, contract, and contract-to-hire staff in facilities, maintenance, warehouse, production, distribution, logistics, agriculture, hospitality, entertainment, and construction management. The biggest differentiator in our firm compared to others is our staffing expertise and that we care about every single associate who works for us and our clients. We aim to make your experience as seamless as possible. Our mission is to ensure that our employees and your hiring managers have a memorable experience with each engagement.

Lincoln industrial websitelogin

What about a CV joint? A popping or clicking noise when turning is a classic symptom of a bad outer CV joint. The noise will also increase as the steering angle is increased. Also, note the condition of a CV joint boot. If it is torn or leaking, the boot should be replaced regardless of the state of the joint. If the CV joint is noisy, it will need to be replaced. What about play in the bearing and flange? Raise the vehicle so the wheel is off the ground and then grab at the 12 and six o’clock positions and rock the tire back and forth. As a rule, you should not feel any play or looseness if the vehicle has a sealed wheel bearing cartridge or hubs with a sealed wheel bearing assembly. A little play is normal on older vehicles with serviceable wheel bearings, but a lot of play is not. Refer to the vehicles service specifications for the maximum amount of acceptable play. Wheel bearing play can be measured with a dial indicator by placing the dial indicator against the wheel flange and rocking it back-and-forth and in-and-out by hand. As a rule, you should see no more than five thousandths of an inch of run out if the bearings are good. What about the road surface? Bearing noise should never be intermittent, but the noise can change due to the harmonics and how the driver hears the road noise due to the road surface. This is why the customer interview is so important. Ask the customer: What does the noise sound like? When does the noise occur? What speed does the noise occur? And, does the noise change when breaking or turning? You should not interrupt the customer or try to diagnose the problem noise during the interview. Always take notes. If you just write on the repair order “Customer states they hear wheel bearing noise,” or “Check for wheel bearing noise,” you’re probably not going to get a proper diagnosis, and this will typically lead to an unhappy customer and an even unhappier technician. I’m Andrew Markel. Thank you very much. This video is sponsored by BCA Bearings by NTN.

Hot tub pump bearing 6203 for the 48 and 56 spa motors. Double-sealed for extended long life and quiet operation. Purchase online, quick shipping.

Why are relay tools essential for diagnostics? Learn how to test relays & circuits like a pro and avoid costly misdiagnoses.

LincolnIndustries jobs

Lincoln industrial websitecatalog

CC: Related Articles - The core of electric vehicle drive units - Electric vehicle radiator and cooling systems - Inside Chrysler EHPS Systems The BCA Hub video series brings together the latest video tech tips on wheel hubs, bearings and seals, featuring the experts you trust. Brought to you by BCA Bearings by NTN. Learn more at bcabearings.com. The classic symptom of a bad wheel bearing is typically a cyclical chirping, squealing or growling noise that changes proportional to vehicle speed. The sound may disappear at some speeds, or occur only at certain speeds. The noise may get worse when turning, or it may disappear momentarily. So, it’s challenging to make a diagnosis based on noise alone. Components like tires, CB joints and brakes can mimic wheel bearing noise. This is why interviewing the customer, going for a test drive and performing a rigorous visual inspection are critical to resolving the customer complaint. Could the noise be in the tires? Tire noise is always proportional to vehicle speed. The noise generated by a tire can be caused by uneven tread patterns, tire construction and even wheel imbalance. This is typically due to missing tire rotations, or, in some rare cases, a shifted belt or a damaged construction. Visually inspect the tire and run your hands over the tire’s tread to detect uneven blocks or feathering of the inner or outer shoulders of the tire. Spin the wheel and look for excessive radial run out with your eye if possible. The tire and wheel assembly can have balance issues that can cause noise proportional to vehicle speed. If you see a wheel that is missing a wheel weight, it could a static or dynamic balance issue. Your best bet might be to use a balancer and see how bad the imbalance is. Also, on a balancer, you can measure rim run out. If the wheel assembly has a high spot as the area comes in contact with the road, it will produce a noise proportional to vehicle speed. What about the brakes? A caliper that is sticking, or a brake pad that is loose and dragging, may make a metallic scraping noise as it rubs against the brake rotor or dust shield. The frequency of the noise will also change proportional to vehicle speed, but will often go away or change when the brakes are lightly applied. Noise that occurs only when the driver is braking likely is a brake problem such as worn pads and not a bad wheel bearing. What about a CV joint? A popping or clicking noise when turning is a classic symptom of a bad outer CV joint. The noise will also increase as the steering angle is increased. Also, note the condition of a CV joint boot. If it is torn or leaking, the boot should be replaced regardless of the state of the joint. If the CV joint is noisy, it will need to be replaced. What about play in the bearing and flange? Raise the vehicle so the wheel is off the ground and then grab at the 12 and six o’clock positions and rock the tire back and forth. As a rule, you should not feel any play or looseness if the vehicle has a sealed wheel bearing cartridge or hubs with a sealed wheel bearing assembly. A little play is normal on older vehicles with serviceable wheel bearings, but a lot of play is not. Refer to the vehicles service specifications for the maximum amount of acceptable play. Wheel bearing play can be measured with a dial indicator by placing the dial indicator against the wheel flange and rocking it back-and-forth and in-and-out by hand. As a rule, you should see no more than five thousandths of an inch of run out if the bearings are good. What about the road surface? Bearing noise should never be intermittent, but the noise can change due to the harmonics and how the driver hears the road noise due to the road surface. This is why the customer interview is so important. Ask the customer: What does the noise sound like? When does the noise occur? What speed does the noise occur? And, does the noise change when breaking or turning? You should not interrupt the customer or try to diagnose the problem noise during the interview. Always take notes. If you just write on the repair order “Customer states they hear wheel bearing noise,” or “Check for wheel bearing noise,” you’re probably not going to get a proper diagnosis, and this will typically lead to an unhappy customer and an even unhappier technician. I’m Andrew Markel. Thank you very much. This video is sponsored by BCA Bearings by NTN.

Overview. C for Metal (CM) is a programming language that allows for creation of high-performance compute and media kernels for Intel® GPUs using an explicit ...

The BCA Hub video series brings together the latest video tech tips on wheel hubs, bearings and seals, featuring the experts you trust. Brought to you by BCA Bearings by NTN. Learn more at bcabearings.com.

is) to slide along the shaft. One exception is the gib-head key which is ... connecting rod must be assembled in the engine with the big end bearing on the.

Search [6206D] > Cross References of [6206DU]. Z9506 · 206SZ · 206P · 6206RS · 6206RS1 · 1206R · 6206RSR · 160206 · ALN30/022 · 206C.

Lincoln industrial websitefree

What about the road surface? Bearing noise should never be intermittent, but the noise can change due to the harmonics and how the driver hears the road noise due to the road surface. This is why the customer interview is so important. Ask the customer: What does the noise sound like? When does the noise occur? What speed does the noise occur? And, does the noise change when breaking or turning? You should not interrupt the customer or try to diagnose the problem noise during the interview. Always take notes. If you just write on the repair order “Customer states they hear wheel bearing noise,” or “Check for wheel bearing noise,” you’re probably not going to get a proper diagnosis, and this will typically lead to an unhappy customer and an even unhappier technician. I’m Andrew Markel. Thank you very much. This video is sponsored by BCA Bearings by NTN.

Explore a wide range of our Clutch Bleeder Kit selection. Find top brands, exclusive offers, and unbeatable prices on eBay. Shop now for fast shipping and ...

LincolnIndustries

What about play in the bearing and flange? Raise the vehicle so the wheel is off the ground and then grab at the 12 and six o’clock positions and rock the tire back and forth. As a rule, you should not feel any play or looseness if the vehicle has a sealed wheel bearing cartridge or hubs with a sealed wheel bearing assembly. A little play is normal on older vehicles with serviceable wheel bearings, but a lot of play is not. Refer to the vehicles service specifications for the maximum amount of acceptable play. Wheel bearing play can be measured with a dial indicator by placing the dial indicator against the wheel flange and rocking it back-and-forth and in-and-out by hand. As a rule, you should see no more than five thousandths of an inch of run out if the bearings are good.

Designed with a double row of heavy duty rollers, thicker outer rings, and special full-contact seals for improved grease retention. BYR: Yoke Roller with Non- ...

Lincolnlubrication catalog PDF

The tire and wheel assembly can have balance issues that can cause noise proportional to vehicle speed. If you see a wheel that is missing a wheel weight, it could a static or dynamic balance issue. Your best bet might be to use a balancer and see how bad the imbalance is. Also, on a balancer, you can measure rim run out. If the wheel assembly has a high spot as the area comes in contact with the road, it will produce a noise proportional to vehicle speed.

Small roller-type one-way clutch in which a cam surface is formed on the outer ring's inner diameter surface.

The classic symptom of a bad wheel bearing is typically a cyclical chirping, squealing or growling noise that changes proportional to vehicle speed. The sound may disappear at some speeds, or occur only at certain speeds. The noise may get worse when turning, or it may disappear momentarily. So, it’s challenging to make a diagnosis based on noise alone. Components like tires, CB joints and brakes can mimic wheel bearing noise. This is why interviewing the customer, going for a test drive and performing a rigorous visual inspection are critical to resolving the customer complaint.

Could the noise be in the tires? Tire noise is always proportional to vehicle speed. The noise generated by a tire can be caused by uneven tread patterns, tire construction and even wheel imbalance. This is typically due to missing tire rotations, or, in some rare cases, a shifted belt or a damaged construction. Visually inspect the tire and run your hands over the tire’s tread to detect uneven blocks or feathering of the inner or outer shoulders of the tire. Spin the wheel and look for excessive radial run out with your eye if possible. The tire and wheel assembly can have balance issues that can cause noise proportional to vehicle speed. If you see a wheel that is missing a wheel weight, it could a static or dynamic balance issue. Your best bet might be to use a balancer and see how bad the imbalance is. Also, on a balancer, you can measure rim run out. If the wheel assembly has a high spot as the area comes in contact with the road, it will produce a noise proportional to vehicle speed. What about the brakes? A caliper that is sticking, or a brake pad that is loose and dragging, may make a metallic scraping noise as it rubs against the brake rotor or dust shield. The frequency of the noise will also change proportional to vehicle speed, but will often go away or change when the brakes are lightly applied. Noise that occurs only when the driver is braking likely is a brake problem such as worn pads and not a bad wheel bearing. What about a CV joint? A popping or clicking noise when turning is a classic symptom of a bad outer CV joint. The noise will also increase as the steering angle is increased. Also, note the condition of a CV joint boot. If it is torn or leaking, the boot should be replaced regardless of the state of the joint. If the CV joint is noisy, it will need to be replaced. What about play in the bearing and flange? Raise the vehicle so the wheel is off the ground and then grab at the 12 and six o’clock positions and rock the tire back and forth. As a rule, you should not feel any play or looseness if the vehicle has a sealed wheel bearing cartridge or hubs with a sealed wheel bearing assembly. A little play is normal on older vehicles with serviceable wheel bearings, but a lot of play is not. Refer to the vehicles service specifications for the maximum amount of acceptable play. Wheel bearing play can be measured with a dial indicator by placing the dial indicator against the wheel flange and rocking it back-and-forth and in-and-out by hand. As a rule, you should see no more than five thousandths of an inch of run out if the bearings are good. What about the road surface? Bearing noise should never be intermittent, but the noise can change due to the harmonics and how the driver hears the road noise due to the road surface. This is why the customer interview is so important. Ask the customer: What does the noise sound like? When does the noise occur? What speed does the noise occur? And, does the noise change when breaking or turning? You should not interrupt the customer or try to diagnose the problem noise during the interview. Always take notes. If you just write on the repair order “Customer states they hear wheel bearing noise,” or “Check for wheel bearing noise,” you’re probably not going to get a proper diagnosis, and this will typically lead to an unhappy customer and an even unhappier technician. I’m Andrew Markel. Thank you very much. This video is sponsored by BCA Bearings by NTN.

SNL520-617NM, Split plummer (pillow) block housing Cast Iron Two-Bolt Mounting Suit Self-aligning ball bearings, Spherical roller bearings, CARB Toroidal ...

2011520 — It's the original type water pump. How tight should I tighten packing nut? Do I need to get the special packing nut wrench or would a channel locks or crescent ...

Learn how to diagnose TPMS issues, spot sensor problems, and perform efficient service to keep customers confident and safe on the road.

Explore AP Emissions Technologies' catalytic converters and exhaust solutions. Discover how our data-driven development process ensures reliable coverage, solves OEM weak points, and consolidates parts for greater efficiency. From the 2020 Subaru Outback to the 2010 Chevy Equinox, AP delivers solutions for exhaust system needs.

8613869596835

8613869596835