Front & Rear Wheel Bearing and Hub Assembly for 2013 ... - 2013 dodge dart front wheel bearing

Sphericalbearinginstallation

The NPB sales & support teams are renowned across the industry for their professionalism, expertise and dedication to our customers’ success.

SKF wheelbearinginstallation instructions

Our priority is the total health of your plant’s assets. Our Vibration Analysis Services can be availed on an "as needed" call out basis, or can be tailored into a Predictive Maintenance Program (PdM) that will improve reliability, increase safety, optimize asset life, and enhance production and operating efficiencies.

We depute our expert Engineers for Emergency Call Basis requirements to detect the root cause of Vibration and accordingly plan a corrective action to avoid any type of losses due to unplanned shutdowns or breakdowns. Our engineers are located across various regions of India in order to offer the customer with our condition monitoring services 24/7

When it comes to solving the toughest challenges, industry-specific knowledge matters. All of our clients benefit from the depth and breadth of our expertise.

SKFbearingInstallation and Maintenance Guide PDF

We have an experienced team of Vibration Experts and operate various Vibration Analysis programmes in a wide range of industries, including Iron & Steel, Cement, Sugar, Power Plant, Petrochemicals & Refineries, Pharmaceuticals, Oil & Gas Production, Engineering Industries, Mining, Oil Rigs, Electrical Rewinding, Atomic Energy, Defence, Marine, etc.

A maintenance action report will be available to the client after each visits (Weekly, Bi-Weekly, Monthly, Bi-Monthly, Quarterly basis, Annual basis)

Shaft alignment is a process to make two or more rotating shafts co-linear, or in the same straight line, both vertically and horizontally. Laser Shaft alignment

How toinstall bearinginto housing

Generally, Vibration Analysis techniques are used on a variety of assets such as pumps, electric motors, internal combustion engines, gearboxes, fans, electrical control panels, compressed air and hydraulic systems etc.

Analysing the vibration patterns recorded enables us to diagnose what faults are occurring in the machine, i.e. bearing, coupling, imbalance, etc and the urgency required for its repair.

Bearinginstallation methods

Anything you need, any questions or concerns you have, you can ask us here. An NPB team member will get back to you promptly.

How toinstallbearings on a shaft

In-situ balancing is the process of balancing a rotor in its own bearings and support structure, in assembled conditions. Our specialised in-situ balancing

How toinstallabearingon a shaft without a press

Our Expert Engineer will attend site to assess which equipment in your plant is suitable for monitoring by vibration analysis. A list of assets will be recommended for inclusion in the vibration programme, based on operation, running hours and criticality and from that a testing schedule will be established. Vibration data is then measured from the machines on a regular basis during our on-site inspection visits and machine condition assessed based on any increases in the parameters.

Install and Removal tools are simple tools that help pull the bearing into the housing or push the bearing out of the housing. This tool ensures the application of even pressure as well as proper centering of the bearing while drawing the bearing into the housing.

BearingInstallation Tool

Enabled by our cloud-computing infrastructure, Our Remote Diagnostic Services allow any company with Internet access to implement a world-class PdM program, or to reduce the cost of an existing one.

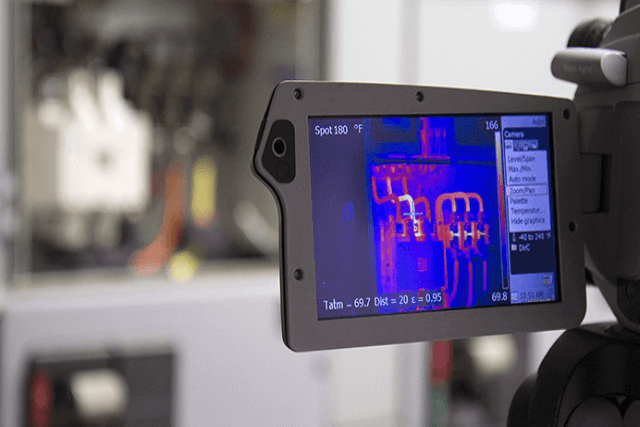

Infrared thermography is a technique of using a non-contact & non-destructive Infrared Scanning Camera to detect invisible Infrared thermal radiation of objects

Since 1979, we’ve been committed to continuous learning and applying that knowledge to help our customers and partners achieve greater success.

Vibration Analysis is the most predominant technique for Detecting, Monitoring & Analyzing the vibration levels and frequencies of industrial machinery, and using that information it determines the "health" of the machine, and its components. Early detection of vibration is essential in order to avoid critical damage, expensive repair and possibly health and safety hazards.

Vibration Analysis can be carried out using various functions such as FFT (Fast Fourier Transform), Time Waveform, 3D ODS (Object Deflection Shapes), FRF (Frequency Response Function), Bode Plot, Bump Test, Run Up Coast Down, Coherence, Orbits etc.

By giving you access to our expertise - and 24/7 access to your machine condition data. (Monthly, Quarterly basis, Annual basis)

8613869596835

8613869596835