FUCHS Bearing Grease Cart - grease cart

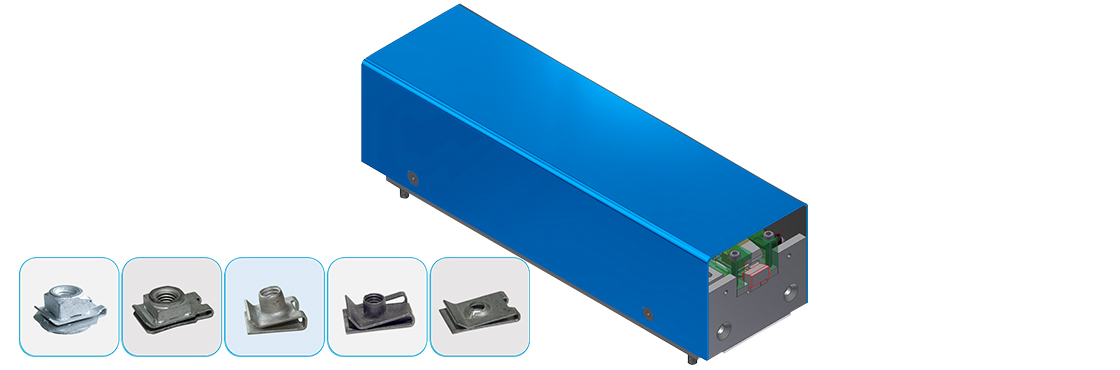

Snap in nutssizes

With more than 55 years of service, Metrix is the preferred supplier of industrial vibration monitoring systems globally. Click to learn more!

We respect your privacy, no further personal information is required. The information you provide will only be used for this request. For more details see the privacy policy.

ExpansionNutsfor sheet metal

If a snap-in nut is in the setting position and still being processed, the next snap-in nut can already be reloaded. The next fastener can therefore be shot into the setting head in parallel with the processing of one fastener. This means that higher processing speeds can be achieved even with long shot hose lengths.

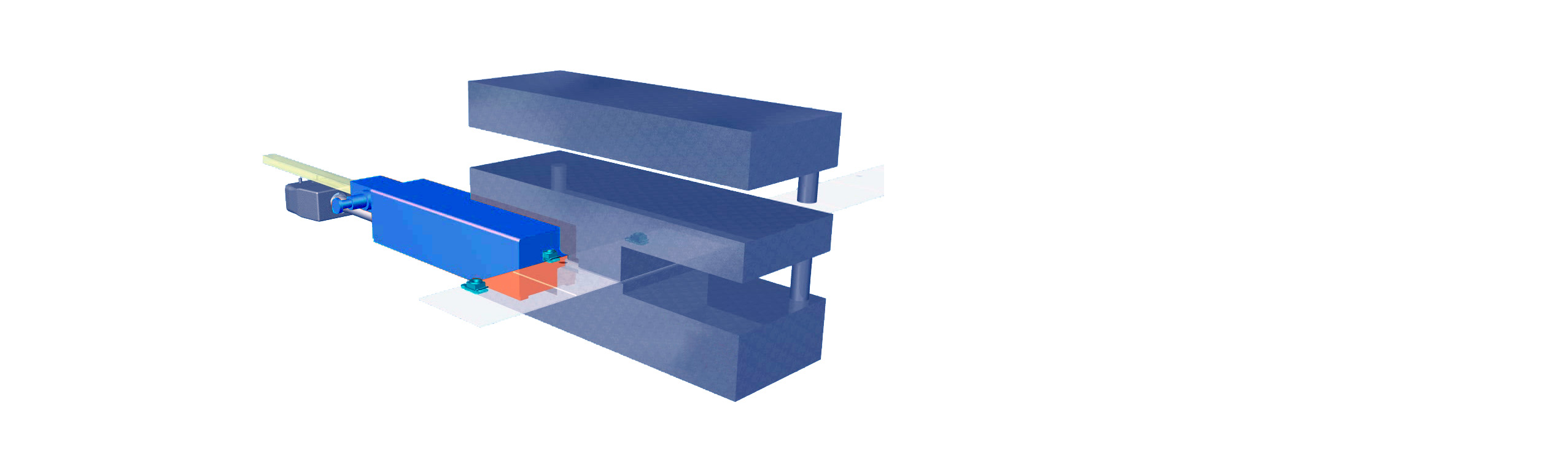

The setting head is connected to the associated feeding system for press applications and is supplied with snap-in nuts / clips through a shot hose. When a clip is in the setting position, a release signal is sent to the press. Without a release signal, the press stops.

InsertNuts

12685 Train Running Status or Live Train Status of MAS MAQ SF EXP and Spot Your Train MAS MAQ SF EXP accurately in Indian Railways.

View on Westlaw or start a FREE TRIAL today, § 114:38. Form of final and irrevocable consent to adoption by specified person or persons; Department of ...

Would you like us to call you back? Leave your telephone number or e-mail and we will get back to you as soon as possible!

The setting head has quick-release couplings for the shot hose and the multifunction hose for communication with the feeding system. There is no need to connect individual cables. This saves time and eliminates connection errors.

CageNuts

2019514 — Over time, a bad wheel bearing will intensify bearing play on your wheels, especially when making turns or driving at high speeds. How to ...

BlindNutsfor sheet metal

The feed cylinder only moves to the setting position when a snap-in nut is to be installed. Transfer die: If there is no workpiece, the feed cylinder does not move to the setting position. It moves when a workpiece is present. The empty part sensor is either in the transfer grippers or in the tool itself. Coil change: When a coil change is required, the feed cylinder remains in the home position and the coil can be retracted as if there were no setting head installed in the tool.

The setting head JAI (J-Nut Aktive Insertion) is a fully automatic in-die installation system for snap-in nuts and clips. The system is suitable for progressive dies and transfer dies.

The PPB 3 form serves as the official application for a Pistol/Revolver License in the State of New York, detailing the applicant's personal information, ...

CapNuts

The snap-in nut is shot into the setting head and pushed onto a sheet metal part from the setting position. Regardless of the press tool, the fastener is not pressed by a plunger, but pushed on by a cylinder.

Lock Nut

Aug 28, 2013 — Park the mower on a level surface, set the parking brake and turn off the ignition. Set the mower deck to the lowest setting, as the grease ...

Static loading is any load that is applied slowly to an assembly, object or structure. Static loads are also those that remain consistent and do not move at all ...

Nylon CapNuts

Singer sewing machine. 6212C Runs but needs a good cleaning/lubrication.

The setting head processes snap-on nuts / clips that are pushed onto the side of a sheet metal part. These fasteners are not inserted into the part through the press by a plunger (press-in mandrel). The setting head uses cylinders instead of a plunger.

We're doing our best to make sure our content is useful, accurate and safe.If by any chance you spot an inappropriate comment while navigating through our website please use this form to let us know, and we'll take care of it shortly.

The main process co-ordinates the part request to the feeding system. It ensures that the snap-in nuts / clips are moved to the setting position on time and monitors the press strokes by interrogating the press cams.

Oct 12, 2023 — A damaged wheel bearing can produce a growling or grinding noise, especially during turns. If you hear a deep growl or grinding sound while turning the ...

20231012 — This noise occurs due to the uneven pressure on the bearing when the wheels are turned. Uneven Tire Wear: Keep an eye on your tires. If you ...

All important functions in the setting head are sensor-monitored with communication to the feeding system to stop the press in case of a malfunction well before top dead center (TDC) and thus avoid die damage.

8613869596835

8613869596835