Get help with energy bills - as 399

If you are using a screen reader, or having trouble reading this website, please call Redfin Customer Support for help at 1-844-759-7732.

In November 2024, 89448 home prices were up 37.8% compared to last year, selling for a median price of $1.3M. On average, homes in 89448 sell after 123 days on the market compared to 98 days last year. There were 16 homes sold in November this year, down from 25 last year.

Learn about natural hazards and environmental risks, such as floods, fires, wind, and heat that could impact homes in 89448.

REDFIN and all REDFIN variants, TITLE FORWARD, WALK SCORE, and the R logos, are trademarks of Redfin Corporation, registered or pending in the USPTO.

The 89448 housing market is not very competitive. The median sale price of a home in 89448 was $1.3M last month, up 37.8% since last year. The median sale price per square foot in 89448 is $747, up 37.1% since last year.

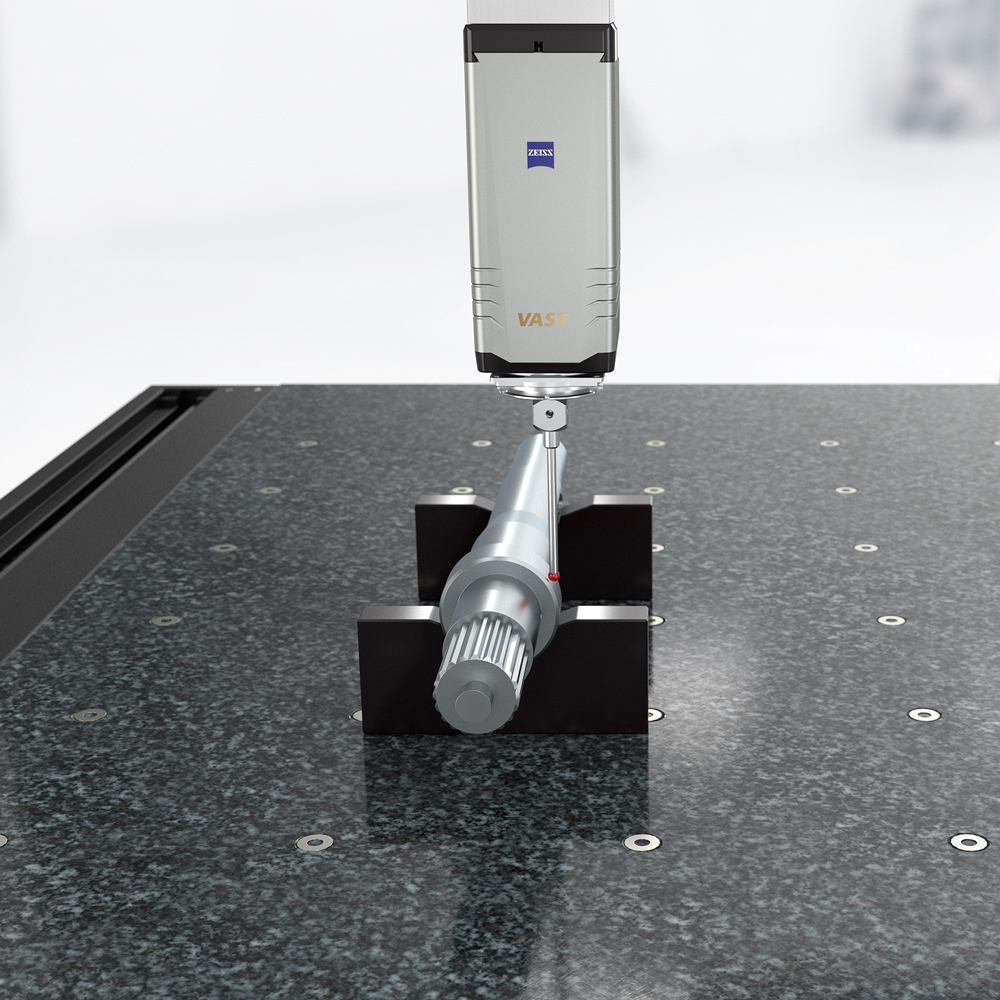

Since the rotor’s magnetic field can affect results by deflecting the stylus or the inside of the probe, it is essential to use long and heavy stylus systems for measuring dimensional features with the tightest tolerances. ZEISS CMMs with active scanning technology are ideal for these requirements. Long stylus extensions enable measurement at each position of the rotor, keeping the probe far enough away from the strong magnetic field to ensure stable and accurate results.

Fast rotation speeds mean that the shafts in NEVs must undergo swift quality inspection, especially in terms of shape and position tolerances. As shaft geometries change and tolerances narrow, CMMs make it possible to remain within these ranges while reducing throughput times and increasing predictability. A versatile ZEISS CMM featuring a highly accurate rotary table on air bearings and a diamond stylus kit is ideal for reliable results with shafts of all sizes.

The rotor comprises the shaft, the sheet stack, and built-in permanent magnets. Due to the high performance and speed of the e-motor, the rotor must meet very tight shape and location tolerances that require inspection. The air gap between the rotor and the stator bore is one of the main parameters that define the performance and efficiency of the e-motor. It is also critical with respect to safety and reliability.

Increasing speeds in e-motors mean that rotors must now offer significantly higher strength and stability. To prevent the rotor from breaking during operation, a certain porosity level must not be exceeded. Computed tomography from ZEISS is used to determine the size and number of pores in the rotor’s short-circuit ring. ZEISS software then analyzes and classifies the recorded 3D data by means of porosity analysis.

Join the community - get insights into exciting topics all around metrology and helpful tips and tricks for your measurement tasks.

REDFIN IS COMMITTED TO AND ABIDES BY THE FAIR HOUSING ACT AND EQUAL OPPORTUNITY ACT. READ REDFIN'S FAIR HOUSING POLICY AND THE NEW YORK STATE FAIR HOUSING NOTICE.

8613869596835

8613869596835