Grease Fitting - grease fitting assortment

Wheel bearingnoise when driving

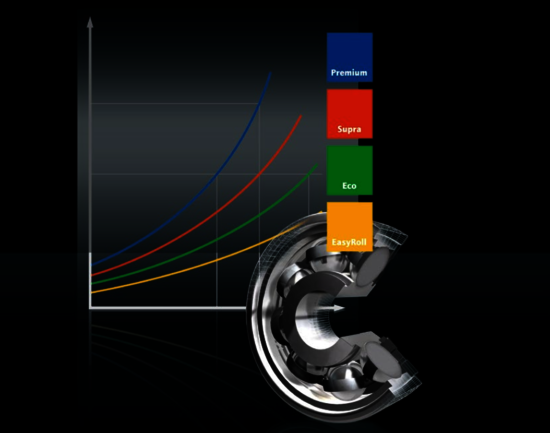

It has never been easier: With our four performance classes Premium, Supra, Eco and EasyRoll, you can also optimize your designs according to economic aspects.

What does a badwheel bearing soundlike at high speed

Needle-roller bearings are characterized by their long, cylindrical rollers with a low cross section height. They are used wherever there are very high, shock-type loads. Karlsruhe-based Findling Wälzlager GmbH offers a comprehensive portfolio of roller bearing technology. In addition to designs from a wide variety of manufacturers and variants, the needle-roller bearing product group also includes needle roller and cage assemblies, drawn cup needle roller bearings with open and closed ends, and…

The use of inner rings ground without twisting, for example in conjunction with radial shaft seals, comes with a series of advantages: Among other things, this makes it possible to prevent lubricants from leaking and increases the service life of the sealing lips. Findling now also offers these components in two performance classes. A high degree of automation during production also allows large-scale production to benefit from attractive conditions and a maximum level of efficiency as well…

Frontwheel bearingnoise symptoms

Needle roller thrust bearings are the most compact roller bearings with the highest load ratings at the same time for purely axial loads. They consist of a cage in which the needles are held. It is particularly important to note that the number of needles may vary while the dimension stays the same, which allows different load ratings to be achieved. The needle sorting used plays a particularly important role when it comes to precision.

How to fix badwheel bearing

Wheel bearingnoise when accelerating

Ball bearingsRoller bearingsNeedle-roller bearingsCam, yoke type track and running rollersHousing bearingsSpherical plain bearingsPlain bearingsLinear technologyLubricantsAccessories

Wheel bearingnoise quick fix

Agricultural technologyPower transmission technologyAutomotiveConveying technologyFood technologyRobotics and automationPackaging technologyOther industries

An essential property of greases and oils is the reliable mechanical separation of the rolling element from the raceway. Depending on the application, you need special types of grease to achieve this function. The following properties in particular affect the function:

Wheel bearingnoise test

We turned customized solutions into standard solutions with a high level of availability, even in small batch sizes. Particularly long-lasting high-performance roller bearings for high loads, high speeds, extreme temperatures and tough environmental conditions – that’s our ABEG® eXtreme series.

Wheel bearing soundwhen turning

That’s why, when procuring roller bearings, it literally pays off to work together with a partner who on the one hand has the necessary application experience and on the other hand not only offers standard products but also an optimized product range for specific industries. Findling Wälzlager GmbH supports its customers in a wide variety of industries with sound consulting and with economically and technologically optimum products.

How do I know if I’ve chosen the right bearing clearance class – C0, CN, CM, C2, C3...? An article from our konstruktiv! series. Tips series.

Our application engineer would be happy to analyze your application conditions and recommend suitable lubricants.Contact for applications consulting

IntroductionYour foundationABEG® in purchasingABEG® in designABEG® in managementABEG® consultingQuality and safety ABEG® test

DevelopmentQuality laboratoryGlobal ProcurementE-ProcurementAudit SupportABEG QuickfinderSpecial greasingDamage analysisAcademyLogistics

It is not the load rating but the right overall technical specifications that are decisive when it comes to the service life and performance of roller bearings.

The world is spinning faster and faster. Complexity is increasing. Time is a precious commodity. Expert knowledge is in demand. We offer you modern roller bearing procurement without ifs and or buts: Experience comprehensive services in the field of rolling bearing technology from a single provider.

Combined radial/thrust bearings hold a special position among rolling bearings: They are capable of simultaneously handling very large radial and axial forces and are characterized by their particularly compact design. Findling Wälzlager offers combined bearings in a wide variety of designs and rolling member pairings.

Rolling bearing damage can have a wide variety of causes and is not necessarily caused by a faulty original product. However, most companies are unable to carry out a detailed damage analysis – good thing Findling Wälzlager’s experts can provide further assistance here: Damage analysis is part of the service portfolio. Findling Wälzlager acts as an independent partner that looks into the causes of the ball bearing defects and helps solve problems.

8613869596835

8613869596835