Grinding Noise When Turning: Possible Causes and ... - grinding noise from front wheel when turning

type:ball;place of origin:shandong,china;brand:as your request;service:OEM one year after-sale service;sample:available;delivery time:2-20 days;mODEL:RAK 1 ...

Rightrear wheel bearingreplacement cost

Jul 30, 2018 - Explore Emelyn Haynie's board "1000-7" on Pinterest. See more ideas ... 1000-7. 240 Pins. ·6y ... more. emelynhaynie. By. Emelyn Haynie.

Buy 2002-2005 Ford Explorer Wheel Hub Assembly Rear Dorman for a low price of $96.97 at PartsGeek. FLAT RATE SHIPPING on most Dorman 951-054 orders.

Battery-operated, fed with 24VDC, or controlled by an external control system, the Memolub automatic lubrication system can be used in a wide variety of ways.

202347 — Pressure gauge fittings are connectors used to connect equipment or pipelines measuring the medium to pressure gauges. Type of pressure gauge ...

Rear wheel BearingAssembly

This will be a sealed hub and bearing assembly. There are different quality levels available ranging from around $70 to $180 for the part alone.

Does your car have noisy wheel bearings? Visit your local Meineke for wheel ... cost to replace your wheel bearings. How Wheel Bearings Are Replaced.

How to checkrear wheelbearings

Badrear wheel bearingsymptoms

Standard lubricant: Oil, Mobil Glygoyl 460. Viscosity 460 [mm2/s] at 40° C. Contains silicone particles. In cartridges of 125 [ml].

Wheel Bearing And Hub Assembly Rear; Rear Drum Brakes. 1 Year Limited Warranty. Material: Steel. Flange Diameter (in): 5.472 Inch.

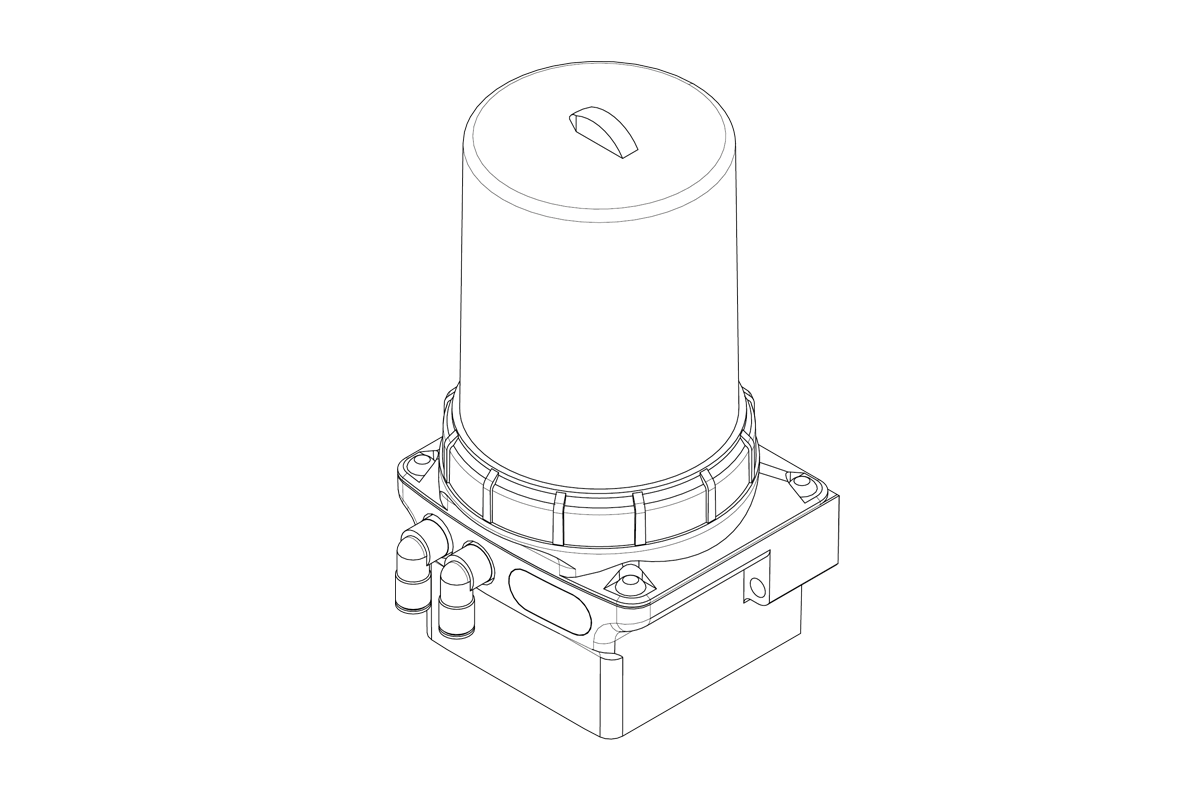

Battery-operated, fed with 24VDC, or controlled by an external control system, the FlexxPump automatic lubrication system can be used in a wide variety of ways.

Video tutorials from AUTODOC Club will help you with this. But keep in mind that the replacement process is quite labour-intensive. You may need a metal brush, ...

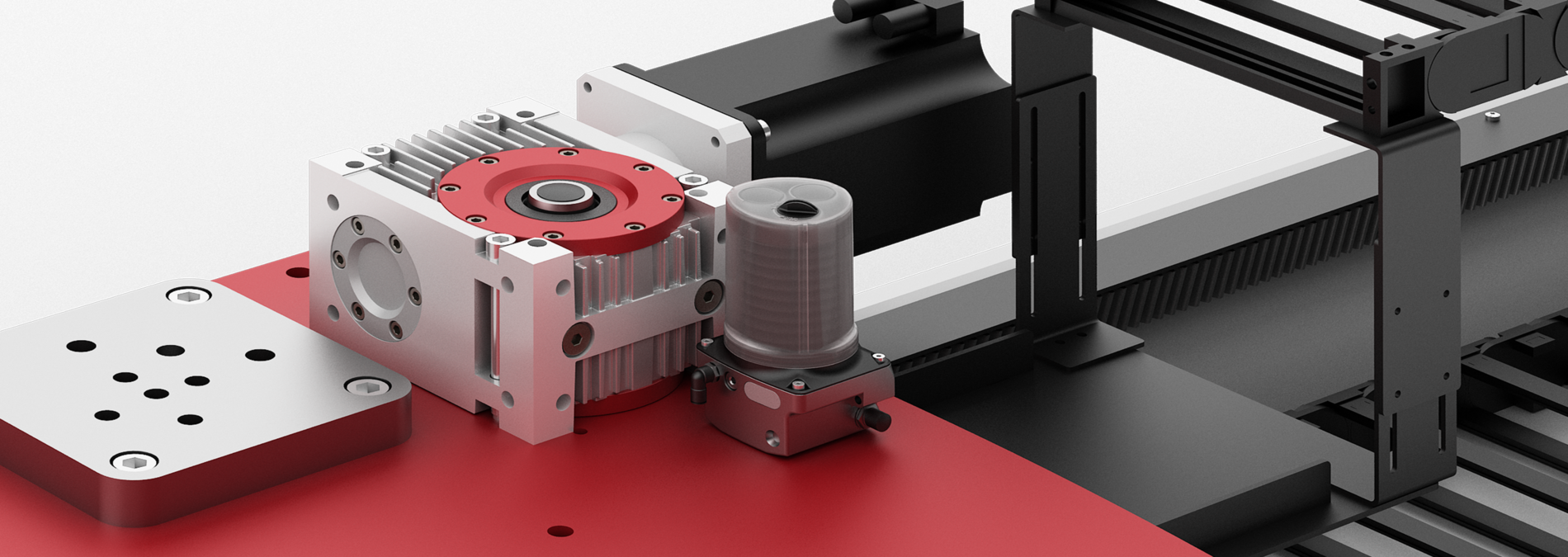

The FlexxPump automatic lubrication system is a lubrication system for Güdel components. The FlexxPump feeds the lubricant from the cartridge into the lines. Depending on the design, the lubricant is distributed through splitters, combined through Y-segments, or distributed directly to the lubrication areas. Rack and pinions are lubricated by lubricating pinions; guideways are lubricated by lubricating elements.

The wheel bearing and hub assembly of your dependable commuter or work vehicle is the ultimate mounting point for the wheel and tire assembly. It has several ...

Rear wheel BearingBike

Get updates about the latest developments of our products, current news, information about events and the latest content on our website.

The lubrication cycle can be programmed via the automatic control system. For this, a 24V connection line must be led to the control system.

For other bearing types, please refer to the respective Timken product catalog reference. Timken offers an extensive range of bearings and accessories in both ...

Rear wheel bearingreplacement cost

The lubrication cycle is set at the pump. Voltage supply via a battery. Lubrication pressure, empty message and signaling of malfunctions can be read at the display.

The lubrication cycle is set at the pump. Voltage supply via cable. Lubrication pressure, empty message and signaling of malfunctions can be read at the display.

The toothed-wheel pump aggregate with container serves to supply lubricant to the central lubrication at systems. For regular lubricant dispensing, the toothed-wheel pump aggregate has to be controlled by a PLC. To this end, a pulse rhythm needs to be sent for every lubrication cycle, by means of a control signal.

The lubrication cycle is programmed by the machine control system (PLC). The voltage supply and connection to the control system are provided via a cable.

Standard lubricant: Güdel H1 high-performance lubrication oil with viscosity 4000 [mm2/s] at +40°C. Food grade with H1 approval. NSF registration number 146621. In cartridges of 400 [ml].

Guideways, racks, and pinions can be lubricated by an optional automatic lubrication system. Depending on customer needs and integration requirements, the selected system reduces the downtimes of the overall plant. Güdel provides documents for installation, integration, and operation. Orientation aids for lubricants, lubrication interval, cycle, or quantity, help to ensure an adequate lubricating film.

The Memolub automatic lubrication system consists of a small lubricant dispenser with progressive distributor with several outputs. The automatic lubrication system lubricates the guideway and rack of the equipped axes automatically. The lubricating pinion unit lubricates the rack. The wiper and lubrication unit lubricates the guideway.

8613869596835

8613869596835