Gut bacteria identified in colorectal cancer patients ... - 25965

Roller bearing vsneedlebearing

Angular contact ball bearings can support a radial load and a one-directional axial load at the same time. When axial loads coming from both directions are to be supported, two or more angular contact ball bearings are combined together.

There are various types of bearings, and we must select the type of bearing most suited to a particular machine's structure and use.

Deep groove ball bearings are the most widely used among all bearings. They can support both a radial load and a certain amount of axial load coming from both directions at the same time. If a bearing to support a very large axial load is needed, the "angular contact ball bearings" explained below are used.

Ball bearing vs roller bearingapplication

As can be seen in Table 1, bearings can be categorized into four groups based on the direction of the force supported and the shape of the rolling elements. For more details, please take a look back at Part 3!

Ball bearing vssphericalroller bearing

Radial roller bearings are roller bearings that can support a force perpendicular to the shaft. They can support an even greater load than radial ball bearings, and there are bearing types that are made to suit the type of roller.

To know if the wheel bearings in your car are going bad, listen for snapping, popping, or clicking sounds when you turn. These sounds are all signs that the joint connecting your wheel to your axel is starting to wear out. Notice if the sound coming from your wheel is changing as you change your speed, and notice if you feel your steering wheel vibrating when you drive. If you feel your wheels wobbling while you drive, you should stop driving immediately, since this is a sign of severe bearing damage. To find out how to evaluate your bearing damage, keep reading! Did this summary help you?YesNo

The contact angle is the angle formed by the direction of the load applied to the bearing rings (races) and rolling elements, and a plain perpendicular to the shaft, when a "radial load" and "axial load" are both applied to a bearing.

Ballandroller bearingapplication

Bearings support forces applied from various directions, and so they can be categorized based on the "direction of the force". Firstly, we will explain about the forces applied to bearings.

Doballbearings have line contact

Wheel bearings are metal balls held by a ring and allow the wheel on your vehicle to spin with as little friction as possible. Over time, bearings can break down due to a lack of lubrication and typical wear and tear. Driving on a bad wheel bearing can be dangerous, and could cause severe damage to your vehicle if you continue to drive on it. Luckily, diagnosing a failing wheel bearing is relatively easy and you can usually determine if there's a problem by listening to your wheels and evaluating any changes in your car's handling.

These use cylindrical rollers as their rolling elements. Cylindrical roller bearings can support an even greater radial load than deep groove ball bearings, and are used in machinery where they will experience strong impacts.

These use needle rollers as their rolling elements. Needle rollers have a smaller diameter than cylindrical rollers, and so (as can be seen in Figure 5) the bearings have a smaller cross-sectional height and contributed to the down-sizing of machinery.

Ball bearing vsjournalbearingturbo

Roller bearing vs ball bearingfriction

In this way, bearings at all times have forces applied from various directions. The bearings are categorized based on which direction the force is coming from and how much force can be applied.

Figure 1 shows the forces applied to the bearing used in a car's wheel with a tire on it. The force generated by the weight of the vehicle (the blue arrow in Figure 1) is applied perpendicular to the axle. Conversely, the centrifugal force generated when the car turns(the red arrow in Figure 1) is applied in the same direction as the axle.

As shown in Figure 8, spherical roller bearings can support a large load, and are used in machines where the shaft is easily bent.

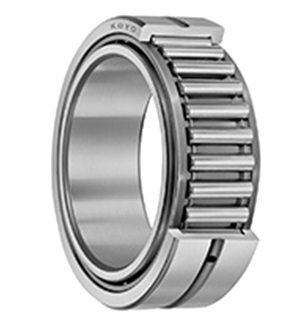

These use tapered rollers in the shape of tapered trapezoids as their rolling elements. Tapered roller bearings are the most widely used among all roller bearings, and can support a radial load and a one-directional axial load at the same time. When axial loads coming from both directions are to be supported, two or more tapered roller bearings are combined together.

These use barrel-shaped convex rollers as their rolling elements. As shown in Figure 7, they are inserted between a spherical outer ring raceway surface and an inner ring raceway surface. This is why the inner ring, rolling elements and cage in a spherical roller bearing are able to rotate while inclined toward the outer ring.

Of the four types of bearings listed in Table 1, radial ball bearings and radial roller bearings are used most often. We will explain a bit about those two types of bearings.

BallandRoller BearingCompany

The force applied to a bearing is called the "load". The force applied perpendicularly to the shaft is called the "radial load", and that applied in the same direction as the shaft is called the "axial load".

There are various types of bearings categorized by the direction and magnitude of the force they can support, and the optimal bearing type is selected, taking the machine's structure into consideration.There are many other types of bearings we didn't introduce in this article. For those who wish to learn more, please click on the Koyo Bearing product-type pages or the catalog below. You can also contact JTEKT directly.

This article was co-authored by Hovig Manouchekian. Hovig Manouchekian is an Auto Repair and Design Specialist and the Manager of Funk Brothers Auto, a family-owned business operated since 1925. With over 30 years of experience in the automotive industry, Hovig specializes in the process of auto repair and maintenance. He is also very knowledgeable in common automotive issues and needs including engine repair, battery replacement, and windshield accessory and maintenance. Hovig's knowledge and hard work have contributed to Funk Brothers Auto winning Angie's List Super Service Award for five consecutive years. There are 7 references cited in this article, which can be found at the bottom of the page. This article has been fact-checked, ensuring the accuracy of any cited facts and confirming the authority of its sources. This article has been viewed 177,285 times.

In this part, we will divide the types of bearings into broad categories, and then explain the main features of bearings.

8613869596835

8613869596835