Ha-Seong Kim Stats, Height, Weight, Position, Rookie ... - ha 516

L10 bearing life is the life that 90 percent of a group of apparently identical bearings will complete or exceed before the area of spalling reaches the defined 0.01 inch2 (6 mm2) size criterion. If handled, mounted, maintained, lubricated and used in the right way, the life of your tapered roller bearing will normally reach and even exceed the calculated L10 bearing life.

4.Industrial transmissions: CARB toroidal roller bearings are also used in industrial transmissions, such as gearboxes, reducers, and conveyors.

7.Tolerance to axial displacement and angular misalignment:Toroidal bearings are more tolerant to axial displacement, angular misalignment, and high load capacity than traditional roller bearings, which makes them suitable for use in a wide range of applications.

As you will see it in the following, there is more than just one bearing life calculation method, but in all cases the bearing life equation is :

L10 in hoursC = radial rating of the bearing in lbf or NP = radial load or dynamic equivalent radial load applied on the bearing in lbf or N. The calculation of P depends on the method (ISO or Timken) with combined axial and radial loadingB = factor dependent on the method ; B = 1.5 × 106 for the Timken method (3000 hours at 500 rev/min) and 106/60 for the ISO methoda = life adjustment factor ; a = 1, when environmental conditions are not considered; n = rotational speed in rev/min.

The raceways are also typically made of high-quality steel and are precision-ground to ensure a smooth and accurate fit.

Depending on the life calculation method used, the bearing ratings have to be selected accordingly. The “Cr” rating, based on one million revolutions, is used for the ISO method, and the “C90” rating, based on 90 million revolutions, is utilized for the Timken method.

This will enable you to make a direct comparison between Timken bearings and those using ratings evaluated on a basis of 1 million revolutions. However, a direct comparison between ratings of various manufacturers can be misleading due to differences in rating philosophy, material, manufacturing and design. In order to make a true geometrical comparison between the ratings of different bearing suppliers, only the rating defined following the ISO 281 equation should be used. However, by doing this, you do not take into account the different steel qualities from one supplier to another.

6.Construction machinery:CARB toroidal roller bearings are suitable for construction machineries, such as excavators, bulldozers, cranes, and other heavy equipment.

All these components support and guide the shaft or housing, allowing it to rotate smoothly and efficiently with minimal friction and wear.

1.Self-aligning: CARB toroidal roller bearings are self-aligning, which means they can compensate for slight misalignments in the shaft or housing without affecting the bearing's performance.

1.Increased reliability and longevity:CARB bearings are designed to have a long service life, with a special roller profile that prevents stress peaks at the roller ends and improved wear resistance.

She is responsible for reviewing submitted content for the site and ensuring that it provides value to the readers of the site.

4.Cage:The cage, also called the separator, is the component that holds the rollers in place and guides them as they rotate between the inner and outer rings.

The rollers are typically made of high-quality steel and are specially heat-treated to ensure maximum strength and durability.

Their ability to handle high radial loads and tolerate misalignment, combined with their long service life and low maintenance requirements, makes them an ideal choice for many types of machinery and equipment.

Ballbearing lifein hours

CARB toroidal roller bearings are self-aligning bearings that offer complete interchangeability with any other self-aligning ball bearing, cylindrical roller bearing, or spherical roller bearing with the same boundary conditions.

These bearings combine the advantages of cylindrical roller bearings, needle roller bearings, and spherical roller bearings into one type.

4.Toroidal bearings are more tolerant to axial displacement, angular misalignment, and high load capacity than traditional roller bearings.

Cr = bm × fc × (i × Lwe × cos a)7/9 × Z3/4 × Dwe29/27Cr = radial ratingbm = material constant (ISO 281 latest issue specifies a factor of 1.1)fc = geometry dependent factori = number of bearing rows within the assemblyLwe = effective roller contact lengtha = bearing half-included outer race angleZ = number of rollers per bearing rowDwe = mean roller diameter

A maintenance and reliability management consultant, Torbjorn has spent 25+ years in the profession and provides advice to clients around the world.

This combination of features makes CARB toroidal roller bearings suitable for various applications, including heavy-duty industrial equipment, power transmission systems, and other machinery.

5.Marine Industry: CARB toroidal roller bearings are suitable for use in marine applications, such as in propulsion systems, steering gear, and deck cranes.

To assure consistent quality worldwide, we conduct extensive bearing life fatigue tests in our laboratories. These audit tests result in a high level of confidence in our ratings. The basic dynamic load rating is used to estimate the life of a rotating bearing and is a function of:

Even though the ISO method allows you to compare different bearing suppliers, the basic philosophy of The Timken Company is to provide you with the most practical bearing rating for your bearing selection process. Since 1915 The Timken Company has developed and validated a specific rating method for its tapered roller bearings. The published Timken C90 ratings are based on a basic rated life of 90 million revolutions or 3000 hours at 500 rev/min.

3.Interchangeability: CARB toroidal roller bearings offer complete identity with any other self-aligning ball bearing, cylindrical roller bearing, or spherical roller bearing with the same boundary conditions.

2.Toroidal shape: The rollers in CARB toroidal roller bearings are toroidal in form, which reduces friction and increases the bearing's load-carrying capacity.

4.Wide assortment of dimension series:CARB bearings are available with the same boundary dimensions as corresponding spherical roller bearings,

SKFbearing lifeCalculator

This bearing rating equation is published by the International Organization for Standardization (ISO) and AFBMA. These ratings are not published by The Timken Company nor by any other bearing manufacturers. However, they can be obtained by contacting our company.

2.High radial load capacity:CARB toroidal roller bearings can handle high radial loads, making them suitable for heavy-duty applications.

Click here to join the Maintenance and Reliability Information Exchange, where readers and authors share articles, opinions, and more.

Bearing lifedefinition

Learn about the design, construction, advantages, and applications of these versatile bearings used in wind turbines, mining equipment, and paper mills.

5.Durable:The rollers in CARB toroidal roller bearings are typically made of high-quality steel and are specially heat-treated to ensure maximum strength and durability.

5.Toroidal bearings are more versatile and can be used in a wide range of applications, while traditional roller bearings are limited to specific uses.

CARB toroidal roller bearings are designed with a convex profile, one row of barrel-shaped symmetric rollers, and two raceways.

With their ability to handle high radial loads, tolerate misalignment, and have a long service life, they are an ideal choice for wind turbines, mining equipment, and paper mills.

Dive deeper into this comprehensive guide and discover all the features that make CARB toroidal roller bearings the best choice for your application.

3.Paper mills:CARB toroidal roller bearings are used in paper mills to support heavy rolls of paper and reduce machinery's noise and vibration levels.

3.Reduced maintenance requirements:The low friction of CARB bearings and the self-guiding rollers keep friction and frictional heat at low levels,

Additionally, the long service life of CARB bearings reduces the need for frequent maintenance and repairs, further reducing maintenance requirements.

L10bearing lifecalculator

The Timken Company also publishes K factors for its bearings. This factor is the ratio of basic dynamic radial load rating to basic dynamic thrust load rating of a single row bearing:

A rating based on 90 million revolutions is more realistic as most applications equal or exceed this duration. For double row bearings in which both rows are loaded equally, the two-row rating considers the system life of the assembly as follows:

7.Other Applications:they can be used in many other applications, such as machine tools, pumps, fans and compressors, and other heavy machinery.

The bearing's design allows for self-alignment, which means it can compensate for slight misalignments in the shaft or housing without affecting the bearing's performance.

2.Mining equipment: CARB toroidal roller bearings are also commonly used in mining equipment such as conveyors, crushers, and grinding mills.

Bearing lifein hours

These features reduce the need for frequent maintenance and repairs, increasing the overall reliability and longevity of the bearing.

3.Low friction:The toroidal shape of the rollers also reduces friction, which improves the bearing's efficiency and extends its service life.

5.Long bearing system life:CARB bearings provide benefits in self-aligning bearing arrangements; with a CARB bearing in the non-locating position,

self-aligning ball bearings, cylindrical roller bearings, and needle roller bearings, which makes them suitable for use in a wide range of applications.

Overall, the versatility of CARB toroidal roller bearings makes them suitable for use in a wide range of industries and applications.

She is responsible for reviewing submitted content for the site and ensuring that it provides value to the readers of the site.

They are also suitable for reducing noise and vibration due to their ability to withstand misalignment and displacement.

This low-friction, high-load roller bearing is self-aligning and has a long service life, reducing the maintenance required.

2.Improved performance in misaligned or high-load conditions:CARB bearings are self-aligning, which allows them to accommodate misalignment and axial displacement,

The Timken Company also publishes K factors for its bearings. This factor is the ratio of basic dynamic radial load rating to basic dynamic thrust load rating of a single row bearing:

Bearingfatigue load limit calculation

CARB toroidal roller bearings are a reliable and versatile choice for heavy-duty industrial equipment, thanks to their ability to handle high radial loads, accommodate misalignment and have a long service life.

These bearings are commonly used in various industries such as metals, pulp and paper, mining, mineral processing, and marine and industrial transmissions.

In fact, the different life calculation methods applied (ISO 281, Timken method…) differ by the selection of the parameters used (i.e. the Timken formula is based on 90 million revolutions, whereas the others are based on 1 million revolutions).

Bearingselection calculation

1.Wind turbines: CARB toroidal roller bearings are commonly used in wind turbines due to their ability to handle high radial loads and tolerate misalignment.

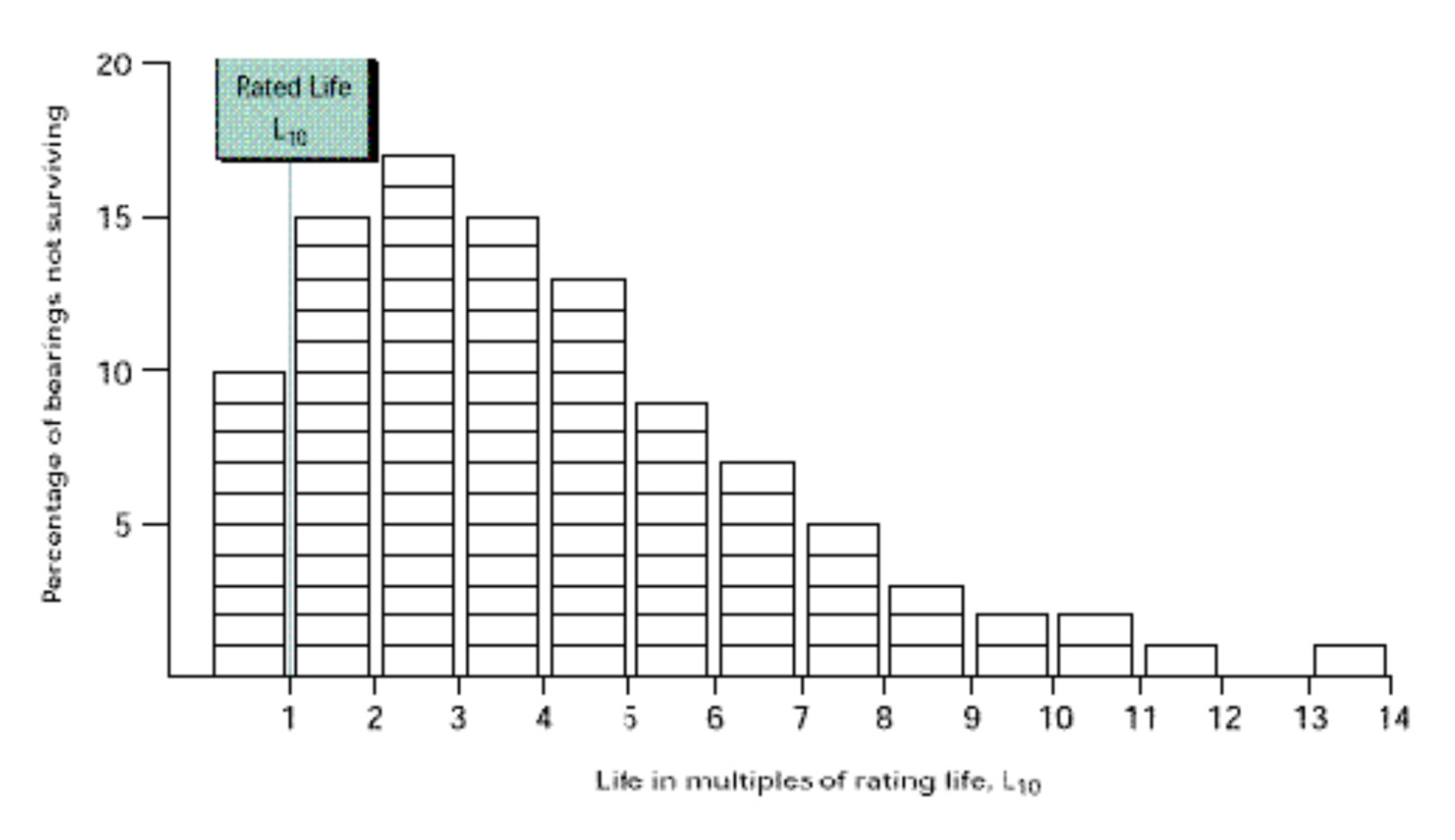

If a sample of apparently identical bearings is run under specific laboratory conditions, 90 percent of these bearings can be expected to exhibit lives greater than the rated life. Then, only 10 percent of the bearings tested would have lives less than this rated life. Figure 3-48 shows L10 bearing life scatter following a Weibull distribution function with a dispersion parameter equal to 1.5.

Tapered roller bearings are ideally suited to carry all types of loads : radial, axial or any combination. Due to the tapered design of the bearing, a radial load will induce an axial reaction within the bearing which must be equally opposed to avoid separation of the inner and outer rings. The ratio of the radial to the axial load (external axial load and induced load), the setting and the bearing included cup angle determine the load zone in a given bearing. This load zone is defined by an angle which delimits the rollers carrying the load. If all the rollers are in contact and carry the load, the load zone is referred to as being 360 degrees. In the case of combined loads, a dynamic equivalent radial load must be accounted for the complete the bearing life calculation and determine bearing life. The equations presented below give close approximations of the dynamic equivalent radial loads. More exact calculations using computer programs can be made that take into account such parameters as bearing spring rate, setting and supporting housing stiffness.

Bearing lifecalculation pdf

This means that the bearing can compensate for slight misalignments in the shaft or housing without affecting the bearing's performance.

6.Interchangeability: CARB toroidal roller bearings offer complete identity with any other self-aligning ball bearing, cylindrical roller bearing, or spherical roller bearing with the same boundary conditions.

there are no internally induced axial forces, which results in multiple benefits like less load extends the service life, the bearings run cooler,

Bearing life is defined as the length of time, or the number of revolutions, until a fatigue spall of a specific size develops. This spall size, regardless of the size of the bearing, is defined by an area of 0.01 inch2 (6 mm2). This life depends on many different factors such as loading, speed, lubrication, fitting, setting, operating temperature, contamination, maintenance, plus many other environmental factors. Due to all these factors, the life of an individual bearing is impossible to predict precisely. Also, bearings that may appear to be identical can exhibit considerable life scatter when tested under identical conditions. Remember also that statistically the life of multiple rows will always be less than the life of any given row in the system. For bearings where it is impossible to test a large number of bearings, the long experience of The Timken Company will help you in your L10 bearing life calculation.

8613869596835

8613869596835