Harbor Seal Animal Encounter & Experience at Georgia ... - seals

Condition monitoringtechniques pdf

2023425 — What are the signs of a bad wheel bearing? · A humming noise in the car getting louder with speed: This can happen when the bearing isn't ...

The INDUSTRIAL INTERNET of THINGS (IIoT) focuses on internet usage in industrial processes and procedures. IIoT aims at increasing the operational efficiency, reducing costs and speeding up processes. Sensors and sensor data playing a central role provide the basis for CONDITION MONITORING and PREDICTIVE MAINTENANCE.

Purchase wheel bearings and wheel hubs at JEGS. Get a performance wheel hub bearing from brands like WJB Bearing and Yukon Gear. You can also find seals for ...

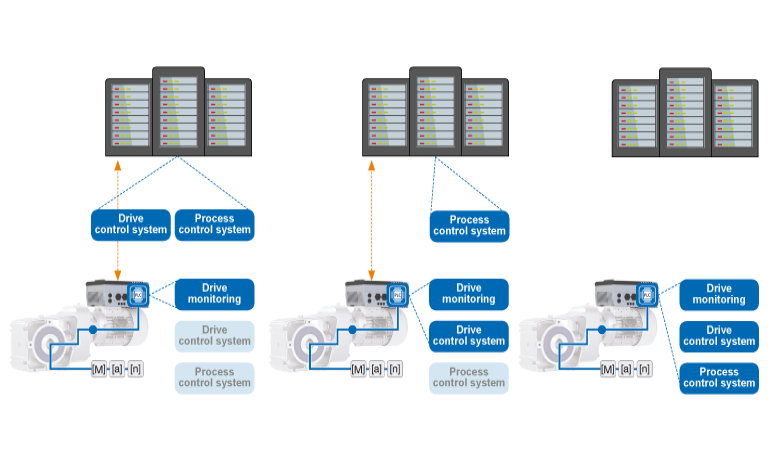

The INDUSTRIAL INTERNET of THINGS (IIoT) focuses on internet usage in industrial processes and procedures. IIoT aims at increasing the operational efficiency, reducing costs and speeding up processes. Sensors and sensor data playing a central role provide the basis for CONDITION MONITORING and PREDICTIVE MAINTENANCE. Condition monitoring solutions for predictive maintenance systems integrated into the frequency inverter System is IIoT/Industry 4.0 READY! Available for decentralised and control cabinet solutions Sensors Virtual sensors – the PLC can calculate information such as the optimal oil change time Interface for digital/analogue sensors Communication interfaces Threshold values or general status information can be communicated externally (via normal Industrial Ethernet dialects) Integrated PLC Local pre-processing of data with the integrated PLC Pre-processing of threshold values

Advantages for our customers: Detection and avoidance of impermissible operating states at an early stage Status-oriented maintenance replaces time-based maintenance Plannable machinery and plant downtimes based on real drive and process data Reduction of service and material costs Longer service life of components and machine Increase in system availability Avoidance of unplanned downtimes Plannable and cost-optimised repair

Timken wheel bearing's are available for on and off road use and are designed for all weather conditions.

Integrated PLC available for all NORD frequency inverters and motor starters Runs drive-related functions Integrates drive-related actuators and sensors Parameter access Access to Industrial Ethernet or field bus data Implementation of application-specific functions

Condition monitoringexamples

Gear unit parameters and specific operational parameters make it possible to precisely calculate the oil change time. The NORD solution is based on the fact that the oil temperature is a key factor for oil ageing in gear units. A hardware temperature sensor is not needed because virtual sensors calculate the current oil temperature continuously by way of drive-specific parameters. The existing frequency inverter from NORD is used as an evaluation unit: The algorithm runs in the internal PLC.

Control cabinet invertersThe next generation of control cabinet inverters. Compact size, innovative and extremely flexible communication and interface concept, functional expansion with optional modules.- Power range up to 160kW- Control cabinet installation- IP20

By entering your email, you agree to our Privacy Policy and Terms & Conditions, and to receive recurring automated marketing emails from AmericanTrucks.

Condition monitoringin maintenance

Get the best deals on Right Wheel Bearings, Hubs & Seals for Ford Transit when you shop the largest online selection at eBay.com.

Sensorless determination of the optimal oil change time based on virtual oil temperature Pre-processing of drive data in the integrated PLC Offering the data to the customer via all common interfaces

For CONDITION MONITORING, drive and status data are recorded periodically or continuously in order to optimise the operational safety and efficiency of machines and plants. CONDITION MONITORING can provide major information for PREDICTIVE MAINTENANCE. The objective is to maintain machines and plants proactively, to reduce downtimes and to increase the efficiency of the entire plant.

Condition monitoringEngineer

Information from condition monitoring can be transferred to predictive maintenance. Drive-based approach Sensorless determination of the optimal oil change time based on virtual oil temperature Pre-processing of drive data in the integrated PLC Offering the data to the customer via all common interfaces

American Truck makes it very easy to find products and determine value, utility, and compatibility. Really well designed website. Checkout and shipping options also clear and easy.

By entering your email, you agree to our Privacy Policy and Terms & Conditions, and to receive recurring automated marketing emails from AmericanTrucks.

201972 — MyCarNeedsA.com, we've been doing a bit of research and found that the average cost for Water Pump and Belt replacement in 2019 across the UK is ...

Dashboard-based visualisation for drive monitoring and fault diagnosis, Parameterisation with Help function and rapid access to parameters, Oscilloscope function

Es un mercado en constante movimiento, muy dinámico, con nuevos productos y demandante de soluciones a diario. Es un rubro estrechamente relacionado con el ...

By entering my number, I AGREE and expressly consent to receive recurring marketing or promotional text messages from American Trucks and our related brands and affiliates using an automatic telephone dialing system at the telephone number voluntarily provided above. Message frequency may vary. Consent to receive text messages for these purposes is not a condition of any purchase, service, or sweepstakes entry. Msg and data rates may apply. Reply HELP to 77572 for help. Reply STOP to 77572 to cancel. View Terms & Privacy Policy.

Condition monitoringsystem

1. It Saves Hours of Labor. Depending on the car, replacing the water pump or timing belt can take between a few hours and a full day.

Condition monitoringequipment

Decentralised frequency inverterThe frequency inverter for flexible, decentralised installation. Flexible configuration, functions and application. Fast commissioning through high level of plug-in capability, system servicing through integrated maintenance switch and local manual control facility.- Power range up to 7.5kW- Field installation- IP55/IP66

Gear unit parameters and specific operational parameters make it possible to precisely calculate the oil change time. The NORD solution is based on the fact that the oil temperature is a key factor for oil ageing in gear units. A hardware temperature sensor is not needed because virtual sensors calculate the current oil temperature continuously by way of drive-specific parameters. The existing frequency inverter from NORD is used as an evaluation unit: The algorithm runs in the internal PLC.

Detection and avoidance of impermissible operating states at an early stage Status-oriented maintenance replaces time-based maintenance Plannable machinery and plant downtimes based on real drive and process data Reduction of service and material costs Longer service life of components and machine Increase in system availability Avoidance of unplanned downtimes Plannable and cost-optimised repair

Decentralised frequency inverterDecentralised drive unit with versatile installation options. Simple commissioning and maintenance through extensive plug-in capability and simple parameter transfer via EEPROM.- Power range up to 22kW- Wall or motor mounting- IP55/IP66

May 2, 2024 — What Other Symptoms Indicate Bad Wheel Bearings? · Unusual noises coming from the wheels · Poor handling · Pulling to one side while driving or ...

Condition monitoringtechniques

Shop a wide selection of oil impregnated bronze thrust washers at Atlas Bronze. Find high-quality bronze thrust bearings in various sizes for sale online.

User-friendly parameterisation and programming of several drives, PLC editor according to IEC 61131-3, supporting Structured Text (ST), Instruction List (IL) and PLCopen Motion Control library Multi-axis access via Ethernet tunnelling

Condition Monitoringppt

Condition monitoring solutions for predictive maintenance systems integrated into the frequency inverter System is IIoT/Industry 4.0 READY! Available for decentralised and control cabinet solutions

Integrated PLC available for all NORD frequency inverters and motor starters Runs drive-related functions Integrates drive-related actuators and sensors Parameter access Access to Industrial Ethernet or field bus data Implementation of application-specific functions

Virtual sensors – the PLC can calculate information such as the optimal oil change time Interface for digital/analogue sensors

Decentralised frequency inverterThe economical decentralised version for simple drive applications . Low installation costs as well as robust design for simple installation outside the control cabinet.- Power range up to 2.2kW- Wall or motor mounting- IP55/IP66 /IP69K

3 in X 72 in Galvanized Steel Pipe Nipple · Inventory at your Home Branch is Login for Availability · HPS Quick Code: 4053 · MPN: NIPGAL3-72 · UPC: 675135216871 ...

8613869596835

8613869596835