Herbalife24® CR 7 Drive Acai Berry 810g - çr7

She is responsible for reviewing submitted content for the site and ensuring that it provides value to the readers of the site.

Equip cars, trucks & SUVs with 2008 Honda Civic Wheel Bearing/Hub Assembly-Rear from AutoZone. Get Yours Today!

Aug 16, 2010 — Most FWD cars have the same drum retaining/bearing nut design whereby this nut is loosened and removed to allow for removal of the drum and any ...

Description. The subject introduces students to a range of public management leadership perspectives and paradigms to help develop the critical thinking and ...

Dec 13, 2021 — The vehicle pulls when you brake. Another symptom of a worn wheel bearing is if the car pulls to one side when you apply the brakes. This can ...

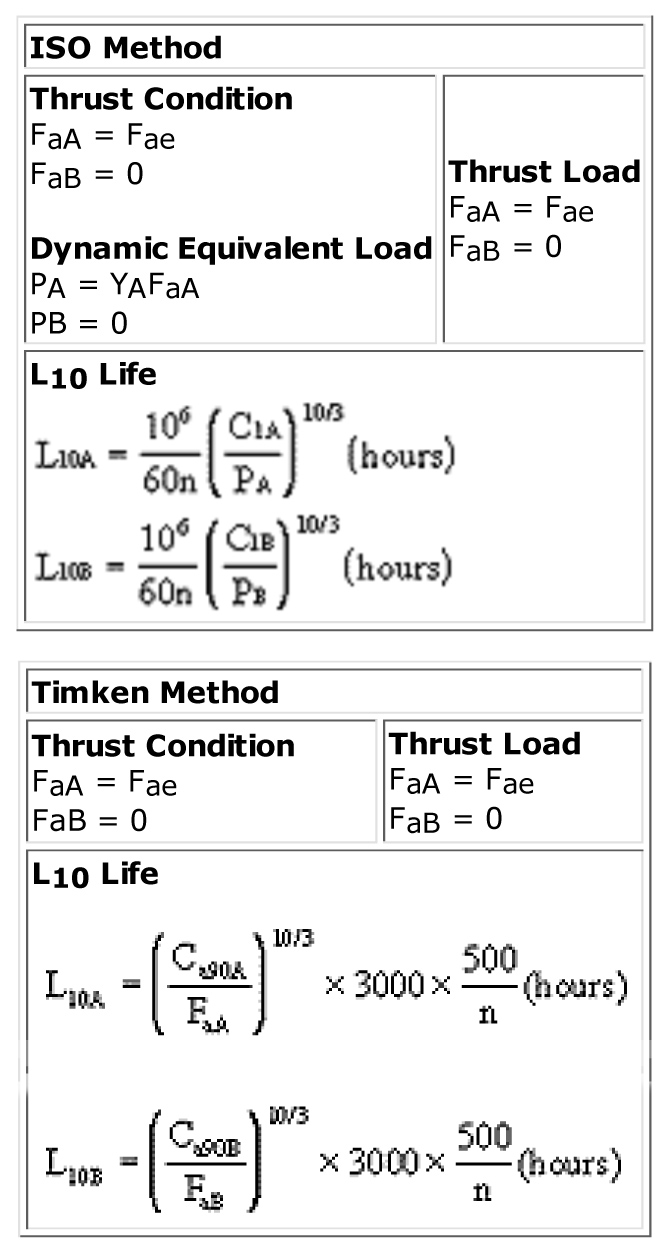

Tapered roller bearings are ideally suited to carry all types of loads : radial, axial or any combination. Due to the tapered design of the bearing, a radial load will induce an axial reaction within the bearing which must be equally opposed to avoid separation of the inner and outer rings. The ratio of the radial to the axial load (external axial load and induced load), the setting and the bearing included cup angle determine the load zone in a given bearing. This load zone is defined by an angle which delimits the rollers carrying the load. If all the rollers are in contact and carry the load, the load zone is referred to as being 360 degrees. In the case of combined loads, a dynamic equivalent radial load must be accounted for the complete the bearing life calculation and determine bearing life. The equations presented below give close approximations of the dynamic equivalent radial loads. More exact calculations using computer programs can be made that take into account such parameters as bearing spring rate, setting and supporting housing stiffness.

More than just noisy or bothersome, bad wheel bearings could also lead to real performance issues like inconsistent braking, spongy steering and handling, uneven tire wear and, in extreme cases, the wheels could fall off. No matter how much (or how little) you know about cars, you don’t want the wheels falling off, right?

Even though the ISO method allows you to compare different bearing suppliers, the basic philosophy of The Timken Company is to provide you with the most practical bearing rating for your bearing selection process. Since 1915 The Timken Company has developed and validated a specific rating method for its tapered roller bearings. The published Timken C90 ratings are based on a basic rated life of 90 million revolutions or 3000 hours at 500 rev/min.

The short answer is: Not for too long. Having bad wheel bearings can range from inconvenient and unpleasant to downright dangerous.

A rating based on 90 million revolutions is more realistic as most applications equal or exceed this duration. For double row bearings in which both rows are loaded equally, the two-row rating considers the system life of the assembly as follows:

The Timken Company also publishes K factors for its bearings. This factor is the ratio of basic dynamic radial load rating to basic dynamic thrust load rating of a single row bearing:

As you will see it in the following, there is more than just one bearing life calculation method, but in all cases the bearing life equation is :

60" 5-Blade Ceiling Fan in Dark Brushed Bronze Finish with Reversible Dark Maple or Dark Walnut Blades

In theory, wheel bearings could last as long as your Dodge. Unlike oil changes or tire rotations, there’s no standard maintenance schedule for replacing them. However, wheel bearings can be damaged if you hit a pothole, smack into a curb or bounce over a speed bump too fast.

... ), Find Details about Needle Roller Bearings, Thrust Roller Bearings from Thrust Needle Roller Bearings (AXK2035) - Nanjing Younarui Bearing Co., Ltd.

A maintenance and reliability management consultant, Torbjorn has spent 25+ years in the profession and provides advice to clients around the world.

Recalls may not affect every vehicle of the same year, make and model. Use your VIN or plate to find out if your specific car has open recalls.

Cr = bm × fc × (i × Lwe × cos a)7/9 × Z3/4 × Dwe29/27Cr = radial ratingbm = material constant (ISO 281 latest issue specifies a factor of 1.1)fc = geometry dependent factori = number of bearing rows within the assemblyLwe = effective roller contact lengtha = bearing half-included outer race angleZ = number of rollers per bearing rowDwe = mean roller diameter

For more on any of these complaints – not to mention more than you ever knew you wanted to know about wheel bearings, read the full article

Click here to join the Maintenance and Reliability Information Exchange, where readers and authors share articles, opinions, and more.

Aug 5, 2021 — Signs And Symptoms Of Failing Wheel Bearings · Strange Noises Bad wheel bearings can cause a variety of strange noises, so it's best to take note ...

She is responsible for reviewing submitted content for the site and ensuring that it provides value to the readers of the site.

20241211 — A bad wheel bearing might seem like a minor inconvenience at first—a faint humming or grinding sound coming from your wheel.

Lug Nut Torque Chart · Gallery · Vehicle Gallery · Powdercoat Gallery · Contact ... HHR, 16"BASE / LS, 2006 - 2011, 100 ft-lbs. IMPALA, SEDAN / 205/75R15, 1961 ...

This bearing rating equation is published by the International Organization for Standardization (ISO) and AFBMA. These ratings are not published by The Timken Company nor by any other bearing manufacturers. However, they can be obtained by contacting our company.

Depending on the life calculation method used, the bearing ratings have to be selected accordingly. The “Cr” rating, based on one million revolutions, is used for the ISO method, and the “C90” rating, based on 90 million revolutions, is utilized for the Timken method.

If you have bad wheel bearings, you might experience the vehicle pulling to one side, sloppy or loose steering, grinding and rattling noises, and uneven tire wear.

If water, grit, salt or sand get to the bearings, the grease in the hub assembly gets contaminated. This will wear down the bearings, and they will eventually give out.

2012 Dodge Avenger wheel bearingreplacement

General waiver or alteration of informed consent is described in paragraph (f) of this section. Except as provided elsewhere in this policy: (1) Before ...

If a sample of apparently identical bearings is run under specific laboratory conditions, 90 percent of these bearings can be expected to exhibit lives greater than the rated life. Then, only 10 percent of the bearings tested would have lives less than this rated life. Figure 3-48 shows L10 bearing life scatter following a Weibull distribution function with a dispersion parameter equal to 1.5.

This will enable you to make a direct comparison between Timken bearings and those using ratings evaluated on a basis of 1 million revolutions. However, a direct comparison between ratings of various manufacturers can be misleading due to differences in rating philosophy, material, manufacturing and design. In order to make a true geometrical comparison between the ratings of different bearing suppliers, only the rating defined following the ISO 281 equation should be used. However, by doing this, you do not take into account the different steel qualities from one supplier to another.

2012 Dodge avengerRearwheel bearingReplacement

Recalls may not affect every vehicle of the same year, make and model. Use your VIN or plate to find out if your specific car has open recalls.

For a national average across all vehicles, the average cost to replace the wheel bearings (for 1 wheel) is about $350 (including parts and labor). But KBB.com goes deeper than that. Based on analyzing 100s of actual repair orders, we put together the Kelley Blue Book Fair Repair Range to show you what you should expect to pay for this repair for your Dodge. Simply tell us the year, model and style of your Dodge and we’ll show you a fair price for the repair.

If you hear noises at the wheels, one explanation might be a need for a wheel bearing replacement at one or more wheels. The noises might be described as rattling, clicking, humming, growling, or squealing. It can be a real symphony of sound if you’re not careful.

The Timken Company also publishes K factors for its bearings. This factor is the ratio of basic dynamic radial load rating to basic dynamic thrust load rating of a single row bearing:

Sometimes this happens if the vehicle is brand new, older, the manufacturer no longer makes vehicles, or we just couldn’t get our hands on the information.

To assure consistent quality worldwide, we conduct extensive bearing life fatigue tests in our laboratories. These audit tests result in a high level of confidence in our ratings. The basic dynamic load rating is used to estimate the life of a rotating bearing and is a function of:

Bearing life is defined as the length of time, or the number of revolutions, until a fatigue spall of a specific size develops. This spall size, regardless of the size of the bearing, is defined by an area of 0.01 inch2 (6 mm2). This life depends on many different factors such as loading, speed, lubrication, fitting, setting, operating temperature, contamination, maintenance, plus many other environmental factors. Due to all these factors, the life of an individual bearing is impossible to predict precisely. Also, bearings that may appear to be identical can exhibit considerable life scatter when tested under identical conditions. Remember also that statistically the life of multiple rows will always be less than the life of any given row in the system. For bearings where it is impossible to test a large number of bearings, the long experience of The Timken Company will help you in your L10 bearing life calculation.

In fact, the different life calculation methods applied (ISO 281, Timken method…) differ by the selection of the parameters used (i.e. the Timken formula is based on 90 million revolutions, whereas the others are based on 1 million revolutions).

L10 bearing life is the life that 90 percent of a group of apparently identical bearings will complete or exceed before the area of spalling reaches the defined 0.01 inch2 (6 mm2) size criterion. If handled, mounted, maintained, lubricated and used in the right way, the life of your tapered roller bearing will normally reach and even exceed the calculated L10 bearing life.

L10 in hoursC = radial rating of the bearing in lbf or NP = radial load or dynamic equivalent radial load applied on the bearing in lbf or N. The calculation of P depends on the method (ISO or Timken) with combined axial and radial loadingB = factor dependent on the method ; B = 1.5 × 106 for the Timken method (3000 hours at 500 rev/min) and 106/60 for the ISO methoda = life adjustment factor ; a = 1, when environmental conditions are not considered; n = rotational speed in rev/min.

8613869596835

8613869596835