High viscosity grease | ABS Lubricants - viscous grease

A wheel bearing is a set of steel balls or tapers that we call "ball bearings" or "tapered bearings." These bearings are held together by a metal ring called a "race." In the center of the wheel, there is a hollow piece of metal called a "hub," and the wheel bearings fit inside the hub to help rotate your wheels.

(4) Installation of open bearings with stamped cages. For bearings with stamped cages, place the inner ring E-Ce flat on the support (end E facing down), then place the components one by one in the correct order, and use the lifting device to install the complete bearing assembly into the bearing housing to ensure the load Region I is correctly aligned. For pin-type cage bearings, put the inner ring E-Ce (E end facing down), inner spacer C (positioning rib down), double-row outer ring B-D and outer spacer B into the bearing housing and pin-type retaining For frame bearings, install the inner ring A-Ca and the single row outer ring A-B into the housing to ensure that the load zone I is properly aligned. Bearings with pin cages can be installed using a lifting device like a bearing with a stamped cage.

How to installbearinginto housing

(7) Install the seal. Loosen the bolts of the end cover and remove the end cover, insert the seal with the required thickness into the end cover, apply grease to the hole of the inner ring, and complete the installation.

2. When installing the bearing, the force should be even and not hammered. If the fit interference is large, put the bearing in mineral oil and heat it to 90°-100°, then install it immediately. the

5. When using bearings, there should be good sealing and dust-proof devices, and the working conditions should be checked frequently. the

The types of bearings we commonly use are: deep groove ball bearings, angular contact ball bearings, self-aligning roller bearings, thrust self-aligning roller bearings, cylindrical roller bearings and thrust self-aligning roller bearings. The use of mounting bearings.

We are back with another market announcement! If you have been following Wrench from the start, you will know that 2021 is a year of growth for us. We are opening new markets

Although wheel bearings are engineered to last the entire lifespan of your vehicle, they can break and get worn out. Most wheel bearings last about 85,000 to 100,000 miles before they need to be replaced. Some vehicles have wheel bearings that last a lot longer, and some vehicles need them replaced fairly quickly. It all depends on the quality of your wheel bearings and your usual driving conditions.

1. When installing the bearing, the bearing seal should be removed, washed and then coated with clean high-quality lubricating oil. the

Your car's exhaust system, and all of the various parts, including the exhaust manifold, are important to keeping your car on the road. Without a properly functioning exhaust system, you could

(1) Configuration of the bearing assembly. Open the bearing package, do not wash off the anti-rust oil, check the bearing components to ensure that the bearing components are complete, the production year is consistent, and the production serial number and installation sequence are indicated by letters. Bearing mating surfaces are marked with 4 load-bearing areas at 90° intervals from I to IV, and the load-bearing areas are marked on the outer diameter of the outer ring of the axially etched line. the

Bearing installationmethods

Your car's wheels are very important as you won't be able to drive anywhere without them. Unless you are a mechanic or you are an avid car enthusiast yourself, you might not know how many parts go into a wheel. There is a tire, rotor, bearing, stator, and capacitor ring, just to name a few. The average car owner doesn't even know the purpose of parts such as wheel bearings, let alone know when they are failing!

Log into our mobile app or website to book a wheel bearing replacement service today! You can book an appointment as a guest if you don't have an account with us just yet. Whether you have an account with us or not, we will need to gather a little information about your type of vehicle and its needs.

Luckily for you, a wheel bearing replacement service isn't a super complicated job, especially for professional technicians. This means it won't be as expensive or time-intensive as a more severe issue. However, if you ignore this issue for too long, other parts might be affected by the bad wheel bearings, adding more repairs and costs to your final bill.

2. Bearings equipped with nylon cages can work continuously and stably for a long time at -40°-120°, and should not work for more than 4 hours at 150°, and the short-term temperature peak can reach 180°.

3. It is advisable not to hammer the inner and outer ring end faces and rollers directly during installation, so as not to crack the inner ring or the middle and small ribs. Usually the user should put the bearing into the mineral oil and heat it to 90°-100° and install the spindle immediately. Do not use local spraying and burning method for bearings, and users should install them with special sleeves when it is difficult to "hot install".

1. When installing the bearing, the bearing oil seal should be cleaned and then coated with clean high-quality lubricating oil.

If you ignore bad wheel bearings, your wheel could stop working while driving, or you could have issues steering your car.

Looking for a mobile mechanic to replace your wheel bearings? Look no further because Wrench is here to help! We have hundreds of ASE-certified mobile technicians all over the country that have the skills to replace your wheel bearings or perform any requested auto repair or maintenance service.

4. Bearings in stock should be cleaned and oiled every other year, and the oil seal package should be kept in good condition. the

3. The warehouse where the bearings are stored should be clean, dry and not allowed to be stored in the same warehouse as chemical products, the relative humidity should not exceed 65%, and the bearings are not allowed to be stored on the ground.

SKFbearing Installationand Maintenance Guide PDF

To keep our customers educated about their car and its various parts, we will go over everything you need to know about wheel bearings and why they are important for your vehicle. Then you will be able to quickly identify wheel bearing problems in the future, or at least know when it is time to visit a mechanic.

Taper lockbearing Installation

The basic requirements for installation are: specially trained installers, check the shape and position tolerance of the bearing mating surface, keep the installation place clean, open the bearing package after the installation preparation is completed, and do not wash off the anti-rust oil of the bearing.

5. The bearing warehouse should be clean and dry without environmental pollution, the bearings should not be stacked on the ground, and the packaging should not be damaged. Bearings in stock for more than 1 year must be re-cleaned and re-oiled.

Once we know which services your car needs and what kind of car you have, we will calculate an auto repair quote for you. This quote will be personalized just for you, so you can know exactly what to expect. We will include everything from the cost of the parts and labor to the estimated time it will take to complete the services. After you have had the chance to look over our auto repair quote, you will pick a date, time, and location for your wheel bearing replacement appointment.

How to install abearingon a shaft without a press

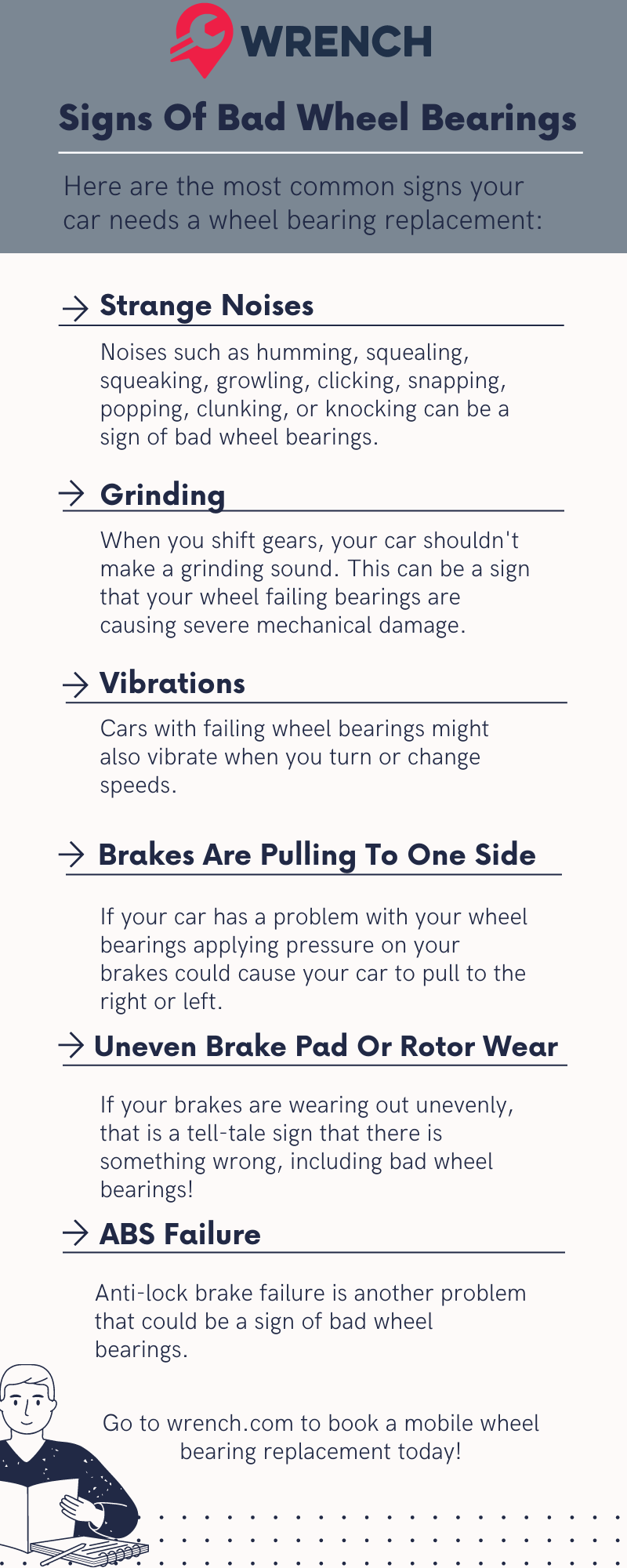

There are many signs you should look out for if you are concerned about your wheel bearings. If you notice any of the signs listed below, you might need a wheel bearing replacement. Keep your eyes and ears alert if you suspect your wheel bearings are going bad, and let your mechanic know which signs you've noticed.

(2) The mating surface of the bearing. In order to prevent the friction and corrosion of the matching surface of the roll neck and the bearing seat, it must be coated with a thin layer of installation paste, and the end cover at the end of the roll body is fixed on the bearing seat with bolts, and the opening of the bearing seat is placed on the plane support .

4. The bearings should have good sealing and dust-proof devices and lubrication during use, and the oil cannot be cut off.

4. Bearings in stock should be cleaned and oiled every other year, and the oil seal package should be kept in good condition.

When changing the load zone for the first time, rotate the outer ring 180° to load zone III; the second time rotate 90° to load zone IV; the third time rotate 180° to II. For tapered roller bearings with seals, after the bearings have been operated for 300h, 600h and 900h respectively, follow the steps below for supplementary inspection: remove the bearing housing and remove the end cover, check the amount and state of grease in the bearing and labyrinth seal. If the grease is discolored or contaminated, fill the bearings and labyrinth seals with new grease. Check the bearing seals carefully, and replace the seals even if they are slightly damaged, and record all maintenance and inspection work on the bearings on the rolling bearing inspection card.

2. Bearings equipped with nylon cages can work continuously and stably for a long time at -40°-120°, and should not work for more than 4 hours at 150°, and the short-term peak temperature should not exceed 180°.

Sphericalbearing installation

Since your wheel bearings are located on your wheel, they need to be able to withstand harsh driving and weather conditions such as potholes, speed bumps, rain, dust, and more. All these harsh conditions can reduce their lifespan, so you should keep an eye out for the symptoms of a failing wheel bearing rather than relying on a timeline.

(8) Heat the labyrinth seal ring in an oil bath, and push the labyrinth seal ring together with the O-ring onto the roll neck. During the cooling process of the labyrinth seal ring, it must be tightly pressed against the end face of the roll .

2. When installing the bearing, the force should be even and not hammered. If the fit interference is large, put the bearing in mineral oil and heat it to 90°-100°, then install it immediately.

How to install bearings on a shaft

(3) Open bearings. First, end E facing down, lift the outer ring D-E and outer spacer D, and put them into the bearing seat, and then lift the parts in the given order and put them into the bearing seat. Pay attention to the alignment of the bearing area, the components installed at the rear must be in full contact with the components at the front, and there must be no inclination or skew.

2. Before the bearing is installed, if it is necessary to add grease to the bearing, the grease must be clean and appropriate.

1. When installing the bearing, the force should be uniform, and it should not be hammered directly. For example, if the fit interference is large, the bearing should be heated in an air heating furnace or an oil furnace with automatic temperature control, and the heating temperature should be strictly controlled below 100°.

Some of these symptoms of bad wheel bearings are very serious and need immediate attention. Before hopping back on the road, make sure to get your car checked out by a qualified mechanic!

1. When installing the bearing, the force should be uniform, and it should not be hammered directly. For example, if the fit interference is large, the bearing should be heated in an air heating furnace or an oil furnace with automatic temperature control, and the heating temperature should be strictly controlled below 120°.

3. The warehouse where the bearings are stored should be clean, dry and not allowed to be stored in the same warehouse as chemical products, the relative humidity should not exceed 65%, and the bearings are not allowed to be stored on the ground.

4. The place where the bearings are stored should be clean and ventilated to avoid moisture. Bearings that need to be stored for a long time should be regularly rust-proofed.

1. The user should select the appropriate fit and axial clearance of the bearing according to the requirements of use. Please check the bearing code after unpacking.

5. When using bearings, there should be good sealing and dust-proof devices, and the working conditions should be checked frequently.

3. The warehouse where the bearings are stored should be clean and clean, and the relative humidity should not exceed 65%.

(6) Swivel bearings. Gently install the second end cover on the bearing seat with 4 bolts at a symmetrical position on the circumference (do not lock the bolts), rotate the bearing seat to a horizontal position, fix the clamp on the end face of the inner ring with a pull rod, and start When it is lighter, the fixture can only touch the end face of the inner ring. For sealed bearings, the lifting device doubles as a clamp. Gradually tighten the tie rods and end cap bolts, and rotate the inner ring slowly and evenly until the inner ring fully fits the inner spacer ring C without gaps. Use a feeler gauge to measure the gap S between the end cover and the bearing housing to determine the seal thickness B. Rigid seal B=S-(0.05~0.1)mm; elastic seal B=1.2Smm.

(9) Push the assembled bearing seat onto the roll neck, regularly check the effectiveness of the seal of the bearing seat and the temperature of the bearing, and change the bearing area of the bearing after the bearing has been working for 1000-1200 hours. Record all maintenance and inspection work of the bearings on the rolling bearing inspection card. Change the load-bearing area of the bearing, disassemble the bearing in the reverse order of installation, clean the bearing parts carefully, then apply oil immediately, visually inspect the raceways and rollers for damage, check the axial play, pack the bearing with new grease, follow the installation instructions Install the bearings and move on to the next load zone.

The first thing we will need to know is what kind of vehicle you have. You should provide us with the year, make, and model, as well as the VIN and license plate number. This information will help us properly prepare for your wheel bearing replacement and any other services you may have requested. If your car requires a specific part, we will make sure we come with the correct tools and parts to perform all of your necessary repairs and services.

(5) Installation of sealed bearings. Sealed tapered roller bearings are mounted with the aid of a special lifting device. Completely assemble the bearing assembly on the lifting gear in the order given. First install the sealing ring E. When installing the grease lubricated bearing, the combination of the roller and the cage must be manually lubricated. Make sure that the load zone I is properly aligned and place the assembled complete bearing in the housing.

Then the rest is up to us! Our mobile technician will arrive on time and completely prepared to get your car up and running again. Go ahead and book a mobile wheel bearing replacement with Wrench today!

3. When installing the bearing, the bearing should be pressed into the component, and knocking is strictly prohibited. the

Bearing InstallationTool

In addition to the danger, it can put a lot of strain on other parts of your vehicle, such as the hub, CV joint, and transmission. If you don't repair your failing wheel bearings soon enough, you might have to spend even more money on auto repair services. You might also notice that your tires wear out faster, which will mean you will need to purchase new tires more often. Overall, all of these potential side effects of bad wheel bearings can end up being more expensive than the original problem.

3. The warehouse where the bearings are stored should be clean and clean, and the relative humidity should not exceed 65%.

No. We don't recommend driving without a properly functioning wheel bearing. Not only is it extremely dangerous for you, but you can also end up injuring or killing other drivers on the road.

Then we will need to know what auto repair or maintenance service you need. If you know your wheel bearings have gone bad, book a wheel bearing replacement appointment! If you suspect that your wheel bearings are the cause of your automotive issues, but you aren't sure, book a diagnostic appointment and our mobile technician will take a look at your car and figure out what's going on.

8613869596835

8613869596835