How Much Does It Cost to Fix an Alternator - alternator bearing replacement cost

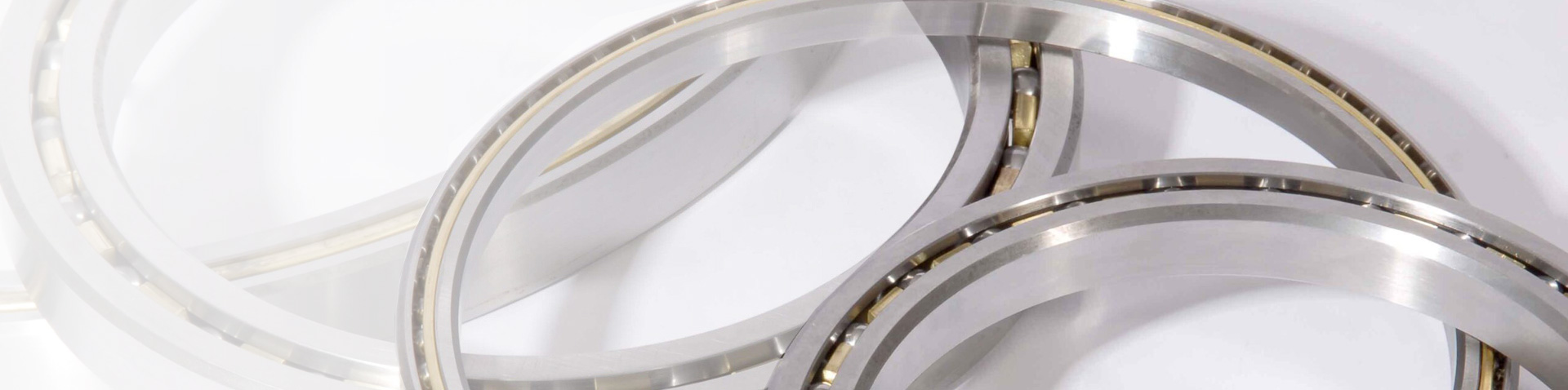

Thin sectionangular contactbearings

Crafted with precision and ingenuity, our Silverthin bearings redefine excellence in engineering. Deviating from the conventional, these extraordinary components embrace a spectrum of benefits that transform design possibilities. With a fundamental commitment to weight reduction, space optimization, and friction minimization, Silverthin bearings establish new benchmarks in efficiency. Their formidable versatility is matched only by their impeccable accuracy in operation.

The C-Type, radial contact ball bearing is designed with deep ball grooves to withstand high loads. Although this bearing is used primarily in applications with radial loads, it can withstand moderate axial loads, reversing axial loads, and moment loads.

The B-Type thin section bearings are a back-to-back pair matched set using two A-Type angular contact bearings that are arranged back-to-back with load lines diverging from the bearing axis. Because the A-Type alone can only take the axial (thrust) load in one direction, they are typically used in a pair matched arrangement. When they are pair matched, they can accommodate axial loading in both directions. One of the two types of arrangements is a back-to-back matched set, also called a duplex pair.

NSK Thin-Sectionbearings

A seal is typically made of rubber or other materials. Sealed bearings are more suitable for applications where the primary concern is preventing contaminates such as dust, dirt, and moisture from entering the bearing.

When specifying this type of bearing for use with axial or moment loads combined with radial loads application speed (rpm) is a real concern. Please contact Silverthin engineering for information on combined load and limiting speeds.

Thin section ball bearingsprice

The T-Type thin section bearings are a tandem mounted pair matched set using two A-Type angular contact bearings that can accept a very high axial load in one direction only. This is different from the back-to-back and face-to-face pair matched bearings, that can accommodate axial loading in both directions.

Thin sectionbearing sizes

Thin section ball bearingssizes

In applications with axial loads in one direction the A-Type, angular contact ball bearing should be used. This bearing also works well in radial or combined radial-thrust applications. The A-Type bearing should never be used alone to support moment loads or reversing axial loading.

Two A-Type bearings are often used as a duplex pairs. Multiple configurations are available for duplex and superduplex. See Type B, Type F, Type T, Type M and Type W below to reference. Contact Silverthin engineering for additional standard and custom configuration options for angular contact Type A thin section bearings.

The X-Type, or 4-point contact, ball bearing is ideal for moment loading. X-Type bearings are designed with gothic arch raceways creating 4 contact points between the balls and the raceways. This design is excellent for moment loading and reversing axial loading. The X-Type bearing can be used for other light loading conditions, but is not recommended in place of the C- or A-Type bearing for pure radial loads.

Thin section ball bearingsfor sale

The Sealed or Shielded C-Type contact ball bearing has radial contact, meaning it primarily supports loads that acts perpendicular to the axis of rotation. Additionally, they are equipped with either seals or shields to provide some level of protection against contaminants, while allowing for smooth rotation.

Our diverse range of Silverthin bearings extends across materials, cage configurations, cross-sectional profiles, internal clearances, and preload options. Lubricants, corrosion-resistant options, contact angles, and tolerance classes are equally at your disposal, accentuating the customizable approach of Silverthin.

The F-Type thin section bearings are a face-to-face pair matched set using two A-Type angular contact bearings that are arranged face-to-face with the load lines converging towards the bearing axis. Because the A-Type alone can only take the axial (thrust) load in one direction, they are typically used in a pair matched arrangement. When they are pair matched, they can accommodate axial loading in both directions. One of these two types of arrangements is a face-to-face matched set, also called a duplex pair.

Thin section bearingsCatalog

A shield is typically made of metal. Shielded bearings are more suitable for applications where the primary concern is larger debris or particles rather than fine contaminants.

The Sealed or Shielded X-Type contact ball bearing or 4-point contact ball bearing is ideal for moment loading. X-Type bearings are designed with gothic arch raceways creating 4 contact points between the balls and the raceways. Additionally, they are equipped with either seals or shields to provide some level of protection against contaminants, while allowing for smooth rotation. This design is excellent for moment loading and reversing axial loading. The X-Type bearing can be used for other light loading conditions, but is not recommended in place of the C- or A-Type bearing for pure radial loads.

Born to thrive under the most rigorous conditions, our Silverthin bearings excel in the face of daunting challenges, consistently outperforming industry expectations. Earning their stripes in aerospace, medical systems, robotics, astronomy instrumentation, and machine tools, they stand as testament to engineering marvels in motion. The cascading benefits of our design ethos extend beyond function, culminating in substantial savings – whether it’s in space utilization, weight considerations, or cost-effective solutions – all realized without compromise.

SKFthin section bearings

Please contact Silverthin for radial bearing use with combined radial loads with axial or moment loading and for limiting speeds and separator selection.

A shield is typically made of metal. Shielded bearings are more suitable for applications where the primary concern is larger debris or particles rather than fine contaminants.

When specifying this type of bearing for use with axial or moment loads combined with radial loads application speed (rpm) is a real concern. Please contact Silverthin engineering for information on combined load and limiting speeds.

Purchase Order Terms and Conditions • Quality Requirements • Return Materials Authorization Sales Order Terms and Conditions • Privacy Policy • Legal Notices

Mechatronics is a privately held marketing, distribution, and manufacturing company that was founded in 1979. Today, the corporation comprises four operating groups that serve diverse markets.

A seal is typically made of rubber or other materials. Sealed bearings are more suitable for applications where the primary concern is preventing contaminates such as dust, dirt, and moisture from entering the bearing.

8613869596835

8613869596835