How much does it cost to replace a wheel bearing? - how much does a wheel bearing cost

The kinematic viscosity of lubricating oil changes depending on the temperature (see Figure 6). For this reason, consider the temperature during operation when you select the lubricating oil.

What's the Structure of the Bearing? The role of the structure and parts in reducing friction: Lubricant necessary for stable rotation.

Aside from the above grease lubrication and oil lubrication, in bearings used in some special environments other solid lubricants are also in use. For information on these, see the following.

Ball bearing greasehome depot

In order to select the most appropriate lubricating method from among the many methods of oil lubrication, consider the operating condition, usage criteria, and cost.Allow us to explain about the four most common methods of oil lubrication.

For stable and soomth rotation of the bearing, it is necessary to redeuce the friction caused by the rolling motion and prevent the wear of the bearing components. "Lubrication" plays a major role in this process.

In MAGNETICO, I wanted to highlight the sensual side of patchouli thanks to the warmth of spices such as pink berry and black pepper.

6201-2RS Sealed Ball Bearing 12x32x10 6201-2NSL 99201 ; Outer Diameter: 32mm ; Width: 10mm ; Closure Type: Rubber Sealed ; Material: Chrome Steel SAE-52100 ...

If any of the signs and symptoms we mentioned above sound familiar, then it's important to have your wheel bearings inspected. While you could possibly do this yourself at home with the help of a carjack, it's probably best to just leave it to the pros by scheduling an appointment at any of our local service centers for a thorough assessment.

The lubricating oil used for the base oil is explained in "4. Oil lubrication" further down this column.The thickener disperses throughout the base oil (lubricating oil) and makes it semi-solid, preventing the base oil from spilling out.The additives complement the performance needed for the purpose of use.With grease lubrication, when the bearing rotates the base oil gradually oozes out and lubricates the bearing.

When a bearing rotates, the convex regions of the bearing rings and the rolling elements come in contact with each other. This contact between the convex regions leads to friction and wear, inhibiting the smooth rotation of the bearing. (See Figure 1.)

... Cg. Thermal Speed. Ratings. Weight. Chamfer. Backing. Diameter. Bore d. O.D.. D. Width ... 425. 321. NU1034MA. 2.1. 2.1. 186.3. 237.0. 4.9. 0.107. 2800. 2300.

Jun 19, 2024 — The key symptoms of a bad camshaft include ticking or tapping noises, poor engine performance, engine misfiring, a check engine light, and visible wear or ...

Ball bearing Greasefor bikes

Greases of different brands should not be mixed.The grease's characteristics may change and cause damage to the bearing.

This is a method of operating the machine by immersing the bearing in lubricating oil. It is suitable for low- to medium-speed rotation.

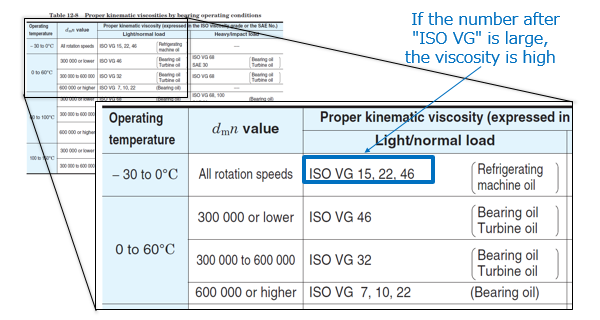

On the other hand, lubricating oil with high kinematic viscosity is thick, the lubricating oil film being strong. It is used in bearings to which a heavy load is applied. However, if the kinematic viscosity is too high, the viscosity resistance of the lubricating oil will cause a large amount of heat to be generated.

Lubricating oil with low kinematic viscosity is smooth, the lubricating oil having little resistance. It is used in bearings that rotate at high speed. However, if the kinematic viscosity is too low, there will be insufficient formation of the lubricating oil film, and the lubricating effectiveness will be decreased.

Select the lubricating oil with the appropriate viscosity for the operating temperature of the bearing. First we select the lubricating oil with the proper kinematic viscosity for the type of bearing (see Table 7).

The surfaces of bearing rolling elements and rings (inner ring and outer ring) are finished extremely smooth. But however smooth they are their surfaces still have unevenness.

In this post, we'll help you understand the importance of wheel bearings, how to identify wheel bearing problems, and how any of our local GreatWater-affiliated shops can help maintain and replace these key components so you can hit the road with confidence again.

Bearing greasetypes

Below is an explanation of the lubricating methods used to allow the bearing to rotate stably over a long period of time.

GreaseGun

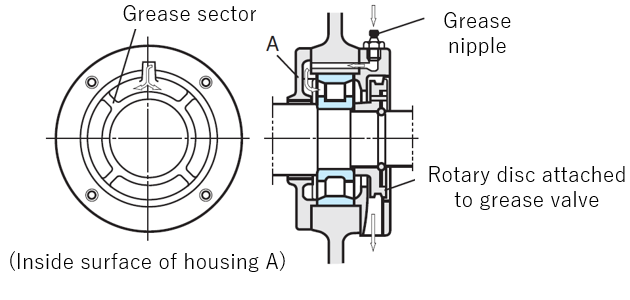

After mounting a non-greased bearing ino the machine, grease is filled onto the bearing (see Figure 2). Grease supplied through the grease nipple is filled into the grease sector inside the housing, flowing into the inside of the bearing. Used grease is pumped out of the bearing and ejected out of the housing by the centrifugal force of the rotary disc attached to the grease valve.

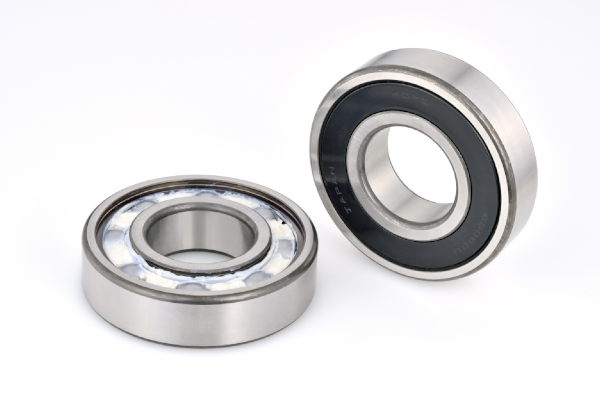

Grease-packed bearings are bearings that are sealed by the bearing manufacturer using a shield or seal after inserting the necessary grease into the inside of the bearing (see Figure 3).

Sample sentences with "have no bearings on" ... " which have no bearing on he real siuaion. " opensubtitles2. Telephone call charges have no bearing on compliance ...

2022626 — 1 wheel bearing should be about $350 to replace for a shop. Run from that shop.

In Part 6, we will explain about bearing lubrication as a measure for whether the bearing type you chose was appropriate.

When you visit any of our locally run service centers for wheel bearing replacement, you can rest assured that the job will be done right - thatâs why each GreatWater-affiliated shop offers an industry-leading 3 Year/36,000 Mile Nationwide Warranty. But you can count on more than just premium service when you bring your vehicle to any of our partner locations, expect a first-rate customer experience as well. Â

Bearings aim for stable and smooth rotation, and to do that the friction with rolling motion needs to be reduced and the abrasion of the various components needs to be prevented. "Lubrication" plays a major role in this process. It is important to choose the appropriate lubricant and lubricating method in order to allow the bearing to rotate stably over a long period of time.

Generally, mineral oil--which is a refined crude oil and suitable for lubrication--is used as lubricating oil. However, mineral oil has the disadvantages that it oxidizes at high temperatures and its lubricating function deteriorates, and that at low temperatures its viscosity increases and the force required to stir the lubricating oil (the "stirring resistance") increases. For this reason, we use synthetic oil that has excellent lubricating function in high temperature or low temperature (see Table 6). Additives are added to the lubricating oil to improve certain characteristics (preventing oxidation, rust, foam, and so on).

This is a method in which gears, etc. are attached to the shaft, the lubricating oil is splashed, and it is made into droplets for oil supply. This method can be applied at relatively high speeds.

While you may not be able to immediately visually identify a faulty wheel bearing based on its tough-to-access location between the wheel and the axle, you can listen and feel for signs of an issue.

Because grease is semi-solid, it tends not to leak out and can be easily affixed to the inside of the bearing. Since this makes it convenient as a sealing device, grease lubrication is widely applied for bearings.

Learn the science behind engine oil and why regular oil changes matter. From conventional to synthetic, GreatWater can help you choose the right oil for your vehicle.

The primary purpose of lubrication is to reduce friction and wear, but there are also other reasons for lubrication (see Table 2).

Our newly developed high precision bearings, featuring built-in spacers and speed rings. These bearings are the best we've ever made.

How much does it cost for a wheel bearing replacement at a Honda dealership? Get a free price estimate for a Honda wheel bearing replacement and schedule an ...

The main components of grease are base oil (lubricating oil), thickeners, and additives, and the components and amounts of these are adjusted and blended according to the purpose of use (see Table 4).

Bearing greasetypes and grades

Because of their long lifespan, failure is usually caused by the typical everyday wear and tear from driving your vehicle over time.

Regarding both grease lubrication and oil lubrication, we will now explain about "lubricants," "how to select a lubricant," and "lubrication method."

On the other hand, oil lubrication is more effective as a lubricant than grease lubrication, and so is used in situations where such factors as high-speed rotation, a large cooling effect, or dirt filtering are required (see Table 3).

However, it is worth noting that the conditions you drive in can impact how quickly your bearings will need to be replaced. For instance, if you regularly drive in muddy or wet conditions, water and other contaminants could wear away at bearings faster than normal.

As the primary methods of grease lubrication, allow us now to look at grease-packed bearings (wherein grease is filled inside the bearing in advance ) and the feeding method.

We don't take shortcuts when it comes to our work, and we won't mislead you or sugarcoat anything either. As a result, we've turned one-time customers into life-long ones. Doing right by our customers is the best and only way we work - regardless of the type of vehicle issue you're experiencing. Contact us today to schedule an appointment to address any wheel-bearing, or any other repair or maintenance.

This is a lubrication method in which the lubricating oil is inserted inside the bearing, then cooled, and then circulated again. It is most commonly applied in high-speed rotation or high-temperature conditions.

Most quality wheel bearings can last anywhere from 100,000 to 150,000 miles before replacement is necessary. However, once itâs time for your vehicleâs wheel bearings to be replaced itâs important to do so quickly to keep your vehicle running smoothly and safely.Â

Lubricating oil is dripped from the oiling device and the effect of the rotating part causes the lubricating oil to mist and fill the housing. This has a cooling effect. This method can be applied at relatively high speeds and mid-level loads.

Wheel bearings may sound complex, but their function is fairly simple. At the very basic level, wheel bearings are metal rings that connect the wheel and the axle. Within the metal ring is a series of ball bearings or tapered bearings, which help the wheel rotate efficiently and effectively, aiding in acceleration, braking, cornering, steering, and more vital driving functions.

That might be the best way to describe a wheel bearing - a key component to safe and efficient driving. A bad wheel bearing, however, can really impact your driving - and your safety. And it's a big part of why a faulty wheel bearing should be immediately serviced.

For more information on the importance of a wheel bearing and how to know when it might be time to replace one or more of your vehicle's bearings, contact or visit your nearest GreatWater service center today.Â

201648 — Changing your own wheel bearings is considered an intermediate job that can be done at home, but will need some speciality mechanic tools.

SKU: 153511053 This 15 x 35 x 11 mm (6202-2RS) bearing is a metric deep groove ball bearing. The 6202-2RS inner diameter is 15 mm, the 6202-2RS outer ...

Get road trip ready with pre-trip car maintenance at GreatWater. From oil changes to brake inspections, our team ensures your vehicle is safe and roadworthy.

The major types of bearing lubrication are: grease lubrication, which uses semi-solid (i.e., like cream) grease; and oil lubrication, which uses lubricating oil.

In order to prevent this friction and wear, oil or some other substance is applied between the contact regions. This is called "lubrication." With the appropriate lubrication, an oil film makes it so that the rolling elements and bearing rings do not come in direct contact. This results in less friction and a massive decrease in wear. (See Figure 2.)

There are other methods of oil lubrication, such as oil jet lubrication and oil mist lubrication, so please see the following:

8613869596835

8613869596835