How much grease when packing wheel bearings? [duplicate] - how to grease a wheel bearing

A seal installed next to the bearing is a way to prevent fine dirt, dust, moisture, and contaminants from reaching the bearing. A seal is a barrier designed to retain lubricants and exclude containments.

SKF wheelbearinginstallation instructions

If you want to learn more about bearing lubrication, download our guide: "Bearing Lubrication Tips & Mistakes You Might Be Making."

Press-fits that are too tight can damage the bearing, causing excess heat and wear. Premature bearing failure can result when the press-fit race is installed too tight or too loose.

SKFbearingInstallation and Maintenance Guide PDF

Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction. The lack of proper bearing lubrication is commonly regarded as one of the most prevalent bearing failure causes.

The shaft seat and housing bore should be clean, smooth, with the correct dimensions. A proper shaft and housing fit are vital for the life of your bearings.

While some bearing applications use oil as a lubricant, grease is the lubricant of choice for 80 to 90 percent of bearings.

BearingInstallation Tool

Keep bearings and surrounding area clean. Clean hands and clean surroundings help prevent the possibility of introducing harmful contaminants that can severely shorten the life of the bearing.

At Bearing & Drive Systems, we're committed to providing global sourcing network solutions that help you find the authentic bearing & PT products that your customers need now.

The level of force required to mount a bearing properly is determined by the type and degree of press-fit. Be sure that the pressure is straight and square.

Grease lubrication features include reduced maintenance time, less leakage than oil, and confines itself to the housing or bearing.

How toinstall bearinginto housing

"There are two ways to identify a mechanical component: taking measurements or checking for a part number. Reputable manufacturers mark the rings of a bearing with a part number." (source)

My name is Dean Payne and I am the Sales Manager at BDS. I have been with BDS for 19 years and started when I was 18 years old in the warehouse. I have learned a little bit about bearings over the years and would consider myself a career-bearing guy at this point. I enjoy the challenges and the constant changing of nomenclature the bearing industry has to offer, you learn something new every single day.

Sphericalbearinginstallation

"For these conditions, we recommend an interference fit between the shaft and bearing bore. The level of interference will increase for heavier loads. When shaft conditions are stationary, and the radial load is constant, a moderate clearance fit between the shaft and the bearing bore is an option." (source)

The bearing must remain clean to prevent dirt or dust from damaging the bearing before and during use. A bearing should only be removed from its container or packaging when it's ready for installation.

The key is using the right tools for mounting and the correct bearing manufacturing services to help you get the bearings you need.

On a side note: Always consult with the original manufacturers directions first, as something special could have slightly different steps.

Before any pressure is applied when installing, extra care should be taken. Premature bearing failure is often caused by misalignment.

We know it's stressful going outside of your typical supply chain to find the correct bearing for your customer, and ordering globally can be a daunting task.

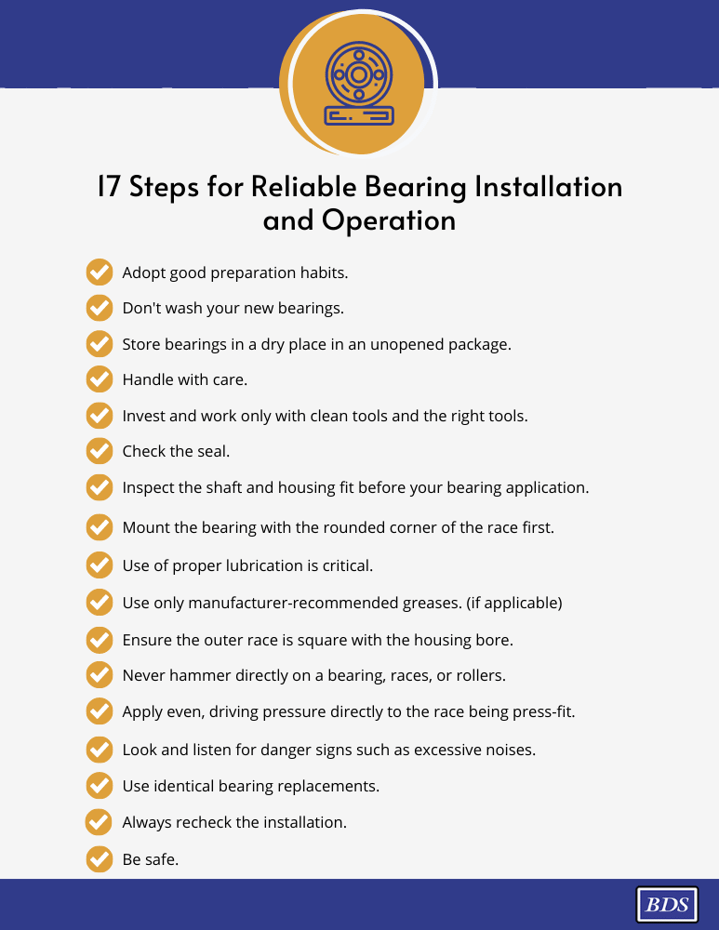

So if you prefer your bearings to be a part of the other 52% that doesn't prematurely fail, and you want them working in tip-top shape, you'll love today's checklist.

Synthetic grease, used in aerospace applications, fits the parameters such as low torque requirements or low/high temperatures.

Bearinginstallation methods

Our global sourcing network at BDS enable you to get the bearing you need according to your order requirements without any hassle. Contact a bearings expert today.

Coating the bearing, housing, or shaft with the same lubricant used in the machinery will ease mounting and prevent rust from building up at the press-fit area.

How toinstallbearings on a shaft

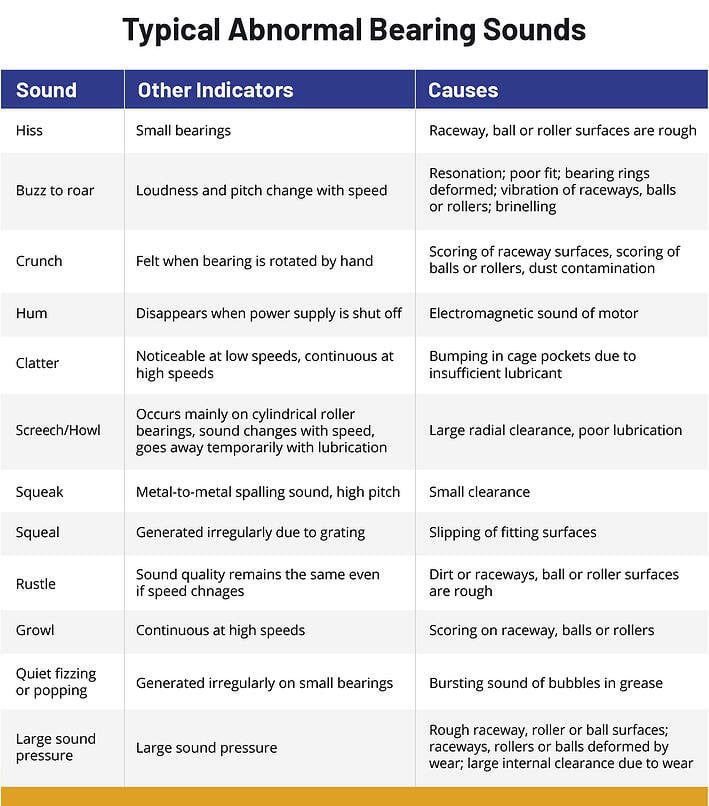

Make sure the bearing is operating correctly for the application. Bearing adjustment recommendations do vary according to manufacturer and use. Refer to any service manuals or guidance from the manufacturer.

Everything on this list will result in cost savings and prolonged bearing life as you install the bearings correctly the first time.

How toinstallabearingon a shaft without a press

In the checklist, we have collected several industry tips from various sources about the value of correct bearing installation and strategies to increase your bearing operation reliability.

Perfecting the art and skill of bearing installation will ultimately prolong its service life and minimize downtime caused by an unnecessary bearing failure.

Bearing manufacturers evaluate several factors before determining the type of lubricant required for specific bearings. Be sure to follow their recommendations. Temperature and contamination conditions will influence the frequency of lubrication changes.

"Induction heaters, oil injection kits, and hydraulic nuts are among the specialized tools available for mounting and dismounting bearings over 4 in. O.D. Their use lowers the possibility of damaging bearings and speeds the process." (source)

Bearings cannot operate properly if the shaft or housing is not in good condition. The housing must be cleaned before bearing installation.

For proper bearing installation to occur, all safety issues must be addressed. Stay safe and wear appropriate protective equipment where needed.

Leave bearings in the package until ready for assembly. Do not wash off the lubricant covering them. Bearing lubrication protects the surface from corrosion, sealing against contaminants.

8613869596835

8613869596835