How much more can I drive with these bad wheel bearings? - what happens if you drive on a bad wheel bearing

What is the lifetime L10h when radial load 150 N is applied to 688ZZ, and oscillates 1,000 time per minute at an oscillating angle of 30º?

Xtrackers company

* Our one or two year plans come with the advantage of no upfront GPS hardware costs, allowing you to get started without a large initial expense. First and last month payment required. Eligibility criteria apply. Early termination may result in penalties. Additional services may have separate charges. We reserve the right to modify or discontinue the offer at any time.

The relationships between the basic dynamic load rating, dynamic equivalent load, and the basic rating life of ball bearings are as follows.

Use geofences to monitor when a vehicle gets to an area (office, job site, home, etc) and how long they stay there. Geofence reports make hourly job billing quick and easy.

In the operating conditions of a bearing, the modification factors which originate in the conditions of the lubrication, temperature and load, etc. is called âthe life modification factor for operating conditions a3. In the case of favorable lubrication conditions, where there is no metal contact due to a lubricating film applied between the raceway surface and balls, and dynamic viscosity of lubricant is above 13 mm2/sï¼13cSt), then a3=1 is used for the effect of the lubrication on the life. When the operating conditions are not favorable (dmn ⦠10,000, deterioration of lubricant, large inclination of inner/outer rings), a3ï¼1 is used. If the operating temperature exceeds 120 ºC, the life becomes shorter because the dimensional change becomes larger, and also the hardness deteriorates. The operating temperature and the life modification factor in such a case are based on the following table.

Xtrackers Wikipedia

Generally, the life can be calculated by the above equation, however, it is insufficient when a high reliability of 90% or more is required depending on the application. Since the fatigue life of bearings has been prolonged due to improved bearing steel in recent years, and the relationship between the lubricant and the bearing life has also been clarified, the following modified life equation is used in ISO281.

Receive notifications about your vehicles, drivers and devices while you are on the go. Work on your business while Trackem keeps an eye on your fleet.

What is the system life when the following radial rotational load and radial static load are applied to 6000HZZ, 6202HZZ and 6304HZZ?

Xtrackeretf

For 6706H 2RU: Cr = 969 N, and Cor = 757 N Ball used: Dw = 1.588 mm, Z = 24 balls According to the table of Dynamic Equivalent Load (Radial Bearings - factors X and Y of deep groove ball bearings) in this section, it becomes:

Xtrackers ETF list

We have a wide range of reports to help you analyze your data and make better business decisions. Reports can be viewed online, or scheduled to come right to your inbox.

The basic rating life of each bearing has a probability of 90%. The system life of multiple bearings becomes even shorter than the shortest basic rating life of each bearing. Considering all the bearings being used as one bearing system, the system life can be obtained by the following equation.

The loads applied to the bearings include drive loads, such as belts and gears, loads that occur in a machine during operation, and the self-weight of equipment supported by bearings. When a bearing is used, it is difficult to obtain the entire load accurately as the bearing load, because different levels of vibration and impact loads are applied. Normally, the load is obtained by multiplying the various factors based on the experience acquired conventionally with the calculated load value obtained theoretically.

We have a wide range of reports to help you analyze your data and make better business decisions. Reports can be viewed online, or scheduled to come right to your inbox.

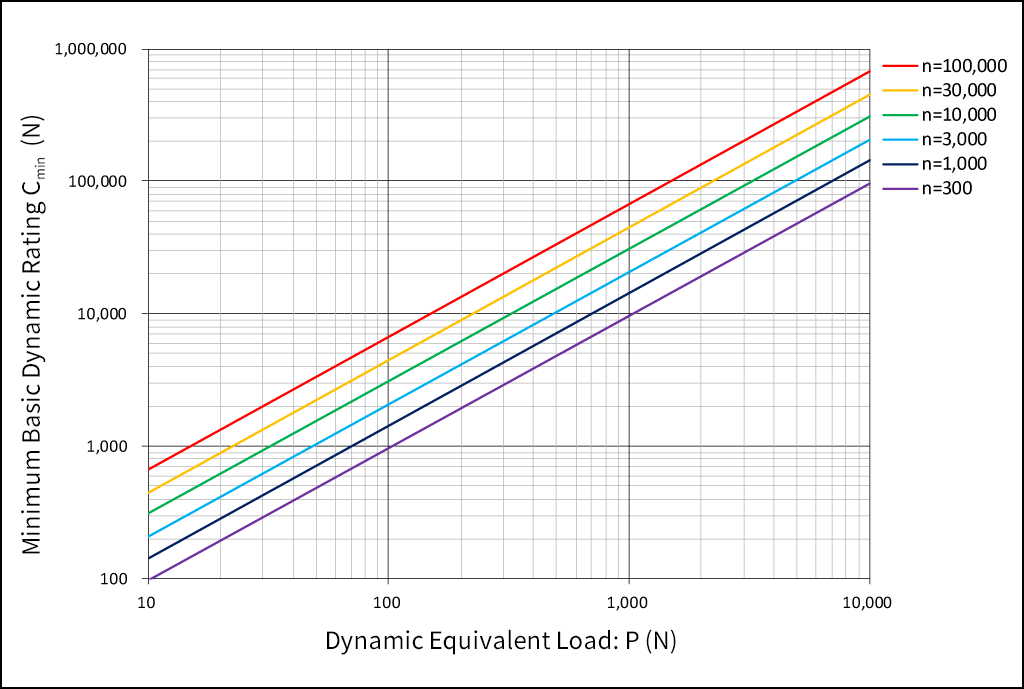

When a large dynamic equivalent load P close to the basic dynamic load rating C is applied to a bearing, the bearing life is reduced in a very short time. However, when a bearing rotates at a high speed with high acceleration, or beyond the limiting speed x 0.5, it is necessary to set to P/C ⥠1% in general, in order to prevent the occurrence of damage due to the sliding of the balls and the raceway surface. A suitable bearing type must be selected based on Cmin = PÃ(L10hÃn/16667)1/3 by clarifying the operating conditions of the machine (dynamic equivalent load P, rotating speed n) and the required lifetime L10h in advance.

The virtual load of the combination of the radial load and axial load that is received when the bearing is static (including very low speed rotations) which is calculated to ensure that the direction and scale become constant is called static equivalent load P0 and is expressed as P0r for radial bearings and P0a for thrust bearings.

Since this is smaller than any "e" value in the table, the following equation can be considered: Pr=Fr=150N. Obtain Cmin (the minimum basic dynamic load rating for operating conditions) as follows:

The radial load and axial load applied to a bearing can be obtained by a theoretical calculation. However, the actually applied load becomes larger than the calculated value due to the vibration and impact of the equipment, therefore the load is obtained by multiplying the factors as follows.

Thus, from, the equation is derived, which indicates that the temporary dynamic equivalent radial load obtained first is correct.

The bearing number with the smallest bore diameter whose Cr is 2163N or higher and the material is SUJ2 in the 60 series will be 606. Calculate the value of Pr (dynamic equivalent radial load of 606), and check that the Pr obtained first (temporary dynamic equivalent radial load) is correct. The axial load ratio of 606 is as follows:

Use geofences to monitor when a vehicle gets to an area (office, job site, home, etc) and how long they stay there. Geofence reports make hourly job billing quick and easy.

XtrackerRoblox

The higher value of static equivalent radial load P0r of a radial bearing is used among the values calculated by the following two equations.

Although the load condition is not constant when a bearing is actually used, there are many cases where the load is a combination of the radial load and axial load. In such a case, it is necessary to calculate the load so that the direction and scale become constant. The calculated virtual load is called dynamic equivalent load P, and is expressed as Pr for radial bearings and Pa for thrust bearings.

What is the life time L10h, L1h where a stainless steel deep groove ball bearing 6706H 2RU is continuously operated at Radial load Fr = 100 N, Axial load Fa = 40 N, Speed n = 1800 min-1? Also, what is the grease life when 6706H 2RU is continuously operated at a bearing temperature of 80 ° C under the same conditions?

Lna: Modified rating life [life when the level of reliability is based (100-n) %] L10: Basic rating life (rev) a1: Life modification factor for reliability a2: Life modification factor for bearing characteristics a3: Life modification factor for operating conditions

The XTracker Solar features a Large 10 Ah battery lasts up to 4 years in standby mode (1 report each day). This GPS tracker has an integrated solar panel for trickle charging or has optional Hard-wired trickle charging options available. Perfect for trailers left on remote job sites, vehicles, RVs, equipment or containers. Attach it to different surfaces using the optional mounting cradle or magnetic cradle.

Xtrackerholdings

The basic dynamic load rating is the constant load applied in a direction under which the basic rating life of the bearing reaches 1 million revolutions. This is the centric radial load in radial bearings, and the centric axial load in thrust bearings. Also, for duplex bearings that consist of two single-row radial bearings with adjusted standouts, the basic dynamic load rating is converted by about 1.62 times that of a single-row bearing.

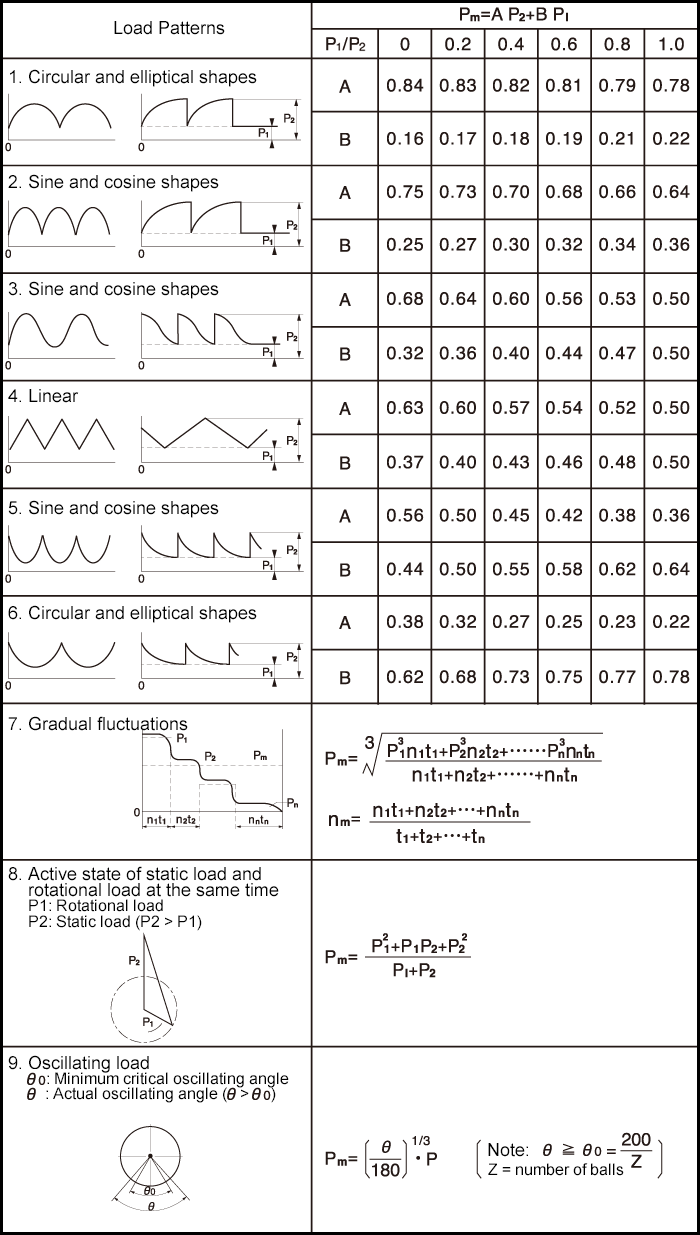

Obtain Pm from Eq. (3) 8 of "Active state of static load and rotational load at the same time," and L10 from the equation for "Life equation (operating hours)":

Select the bearing that has the smallest bore diameter, when selection conditions for the bearing are as follows: Material: SUJ2, Deep groove ball bearing: 60 series, Required life time: 10,000 hours or more, Radial load Fr=150N, Axial load Fa=20N, Rotating speed n = 5000 min-1.

The dimensional change of a bearing with normal heat treatment applied becomes larger at temperatures exceeding 120 ºC. Although a reduction in the basic dynamic load rating due to the deterioration of the hardness is unavoidable, the dimensional change can be suppressed even at high temperatures by performing a dimensional stabilization treatment.

As shown in the figure, when radial loads F1 and F2 are applied, the load distributed on Bearing I and Bearing II can be obtained by the following equation.

View the travel route for today or for any day in the past. Gain visibility on time and distance driven, how many stops were made and for how long.

When a certain static load is applied to a bearing, a local permanent deformation of an indent shape occurs in the contact portion between the balls and raceway surface. This permanent deformation causes a poor rotating condition that also increases noise and vibrations, therefore, the basic static load rating Co is defined as follows as a reference of the acceptable static load. The basic static load rating of a ball bearing is the static load where the calculated contact stress becomes 4200 MPaï¼429kgf/mm2ï¼ in the contact portion between the balls and raceway, and the sum of the permanent deformation produced between the balls and raceway becomes about 1/10000 of the ball diameter. The value of the basic static load rating Co is expressed as Cor for radial bearings and Coa for thrust bearings. In addition, the Co of duplex bearings that consist of two single-row radial bearings with adjusted standouts is converted by twice that of a single-row bearing.

Receive notifications about your vehicles, drivers and devices while you are on the go. Work on your business while Trackem keeps an eye on your fleet.

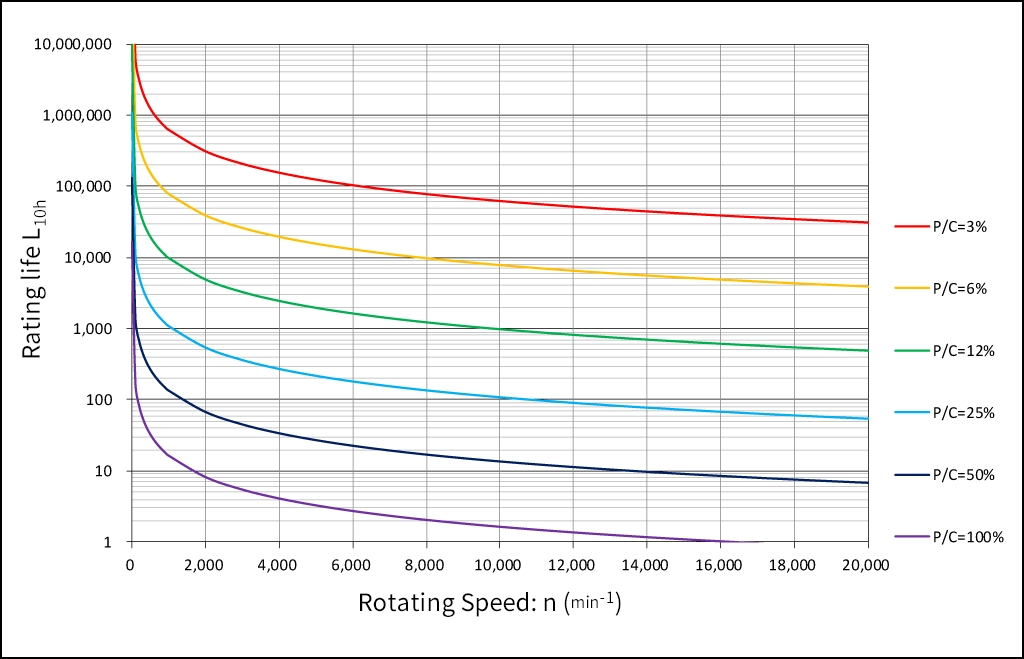

As shown in the following table and graph, generally, it is necessary to consider selection of a bearing using [dynamic equivalent load] / [dynamic load rating] = P/C = [normal load ratio: 6 to 12%] as a guide.

Xtrackers owner

Assuming that the bearing bore diameter ⦠10mm, outside diameter ⦠20mm, and width ⦠5mm are for the space to assemble a bearing, and the load condition is Fr (radial load) = 120 N and rotating speed n = 1200 min-1, select the type of single-row deep groove ball bearing with a life factor fhâ§4.

Xtrackerreview

If P and n are known based on L10h= 50,000 hours as a reference, the minimum basic dynamic load rating: Cmin can be obtained easily using the following graph. It is recommended to select a bearing type with a basic dynamic load rating: C higher than this Cmin. However, rotating speed: n must not exceed the limiting speed of the selected bearing type.

View the travel route for today or for any day in the past. Gain visibility on time and distance driven, how many stops were made and for how long.

When the scale and direction of the load applied to a bearing fluctuates, it is necessary to obtain the average load so that it becomes equal to the bearing life under its loading condition.

When the fatigue life is prolonged due to improvements in the manufacturing method and heat treatment condition, etc. of the bearing material, modify the value according to the life modification factor for bearing characteristics a2. In the case of the standard bearing material of our company, modify the value to a2=1.

The acceptable static equivalent load of a bearing is determined by the basic static load rating, however, the usage limitations of a bearing differ by the operating conditions and required performance. Therefore, in order to examine the safety integrity, the value can be calculated by the following equation using an experiential safety factor.

8613869596835

8613869596835