How Much Oil To Use For Wet Compression Test - compression wet test

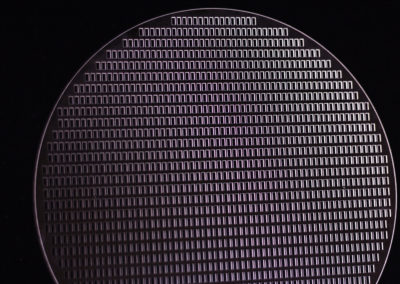

Diamond Tool Machining: Diamonds are the preferred tooling choice for the CNC machining of ceramics. Diamond-coated tools provide unparalleled hardness and resistance to wear, enabling precise cuts and finishes. Advanced techniques allow for customization of the tool’s geometry and coating, optimizing performance for specific ceramic types and delivering smoother finishes and extended tool life. Bullen has ground thousands of ceramic parts utilizing the cutting edge (pun intended) in diamond tooling, let our experience save you time on your next project

Precision ceramic machiningcompanies

PrecisionCeramics UK

So, whether you’re in search of flawless ceramic components for aerospace applications or intricate pieces for cutting-edge electronics, be assured that with Bullen, you have a partner who not only understands the science of ceramic machining but is also deeply passionate about delivering unparalleled precision and quality.

In this journey, challenges serve as opportunities to showcase our expertise. With unwavering dedication and a commitment to excellence, we navigate the complex terrain of ceramics, transforming raw materials into finely engineered components.

Ceramic machining is a precise blend of engineering acumen, innovation, and problem-solving. As a committed machining solutions provider, Bullen takes immense pride in mastering the intricacies of ceramic materials and techniques. From precision diamond tooling to state-of-the-art laser technology, we have the experience to help your technical team bring their design to life.

Precision ceramic machiningnear me

PrecisionCeramics USA

Ultrasonic Machining: This method capitalizes on ultrasonic vibrations to create controlled abrasions on ceramic surfaces. By inducing micro-scale fractures as the tool contacts the ceramic, ultrasonic machining enhances cutting precision and is particularly useful for intricate designs and delicate ceramics. Our ultrasonic drilling process is non-chemical, non-thermal, has no heat affected zone and therefore almost no depth of damage ensuring a clean and reliable surface for your application.

Ceramic materials have been recognized for their outstanding attributes, including high-temperature stability, superb electrical insulation, and exceptional hardness. However, their unique properties also present distinct challenges due to their brittleness and high hardness. This is where Bullen’s experience in ceramic machining comes into play.

As a seasoned industry expert and your trusted source for machining solutions, Bullen is excited to take you on a deep dive into the world of ceramic machining. In this blog post, we’ll delve into the details of working with ceramics, explore cutting-edge machining techniques, and dissect the challenges and effective solutions that define ceramic machining as a specialized discipline.

Honeywell Wind Turbine has an increased operating span over traditional turbines with a start-up speed as low as 0.5 mph (0.2 m/s), with an auto shut off at 38 mph (17.0 m/s), traditional gearbox turbines require minimum wind speeds of 7.5 mph (3.5 m/s) to cut in and start generating power. The Honeywell Wind Turbine is designed to be installed by a licensed electrician wherever energy is consumed, turning homes and businesses from points of total consumption to distributed energy sources, in a cost effective and efficient manner.Additional Prep Fees May Apply

8613869596835

8613869596835