How much should I expect to pay in labor for a wheel ... - how much is a bearing replacement

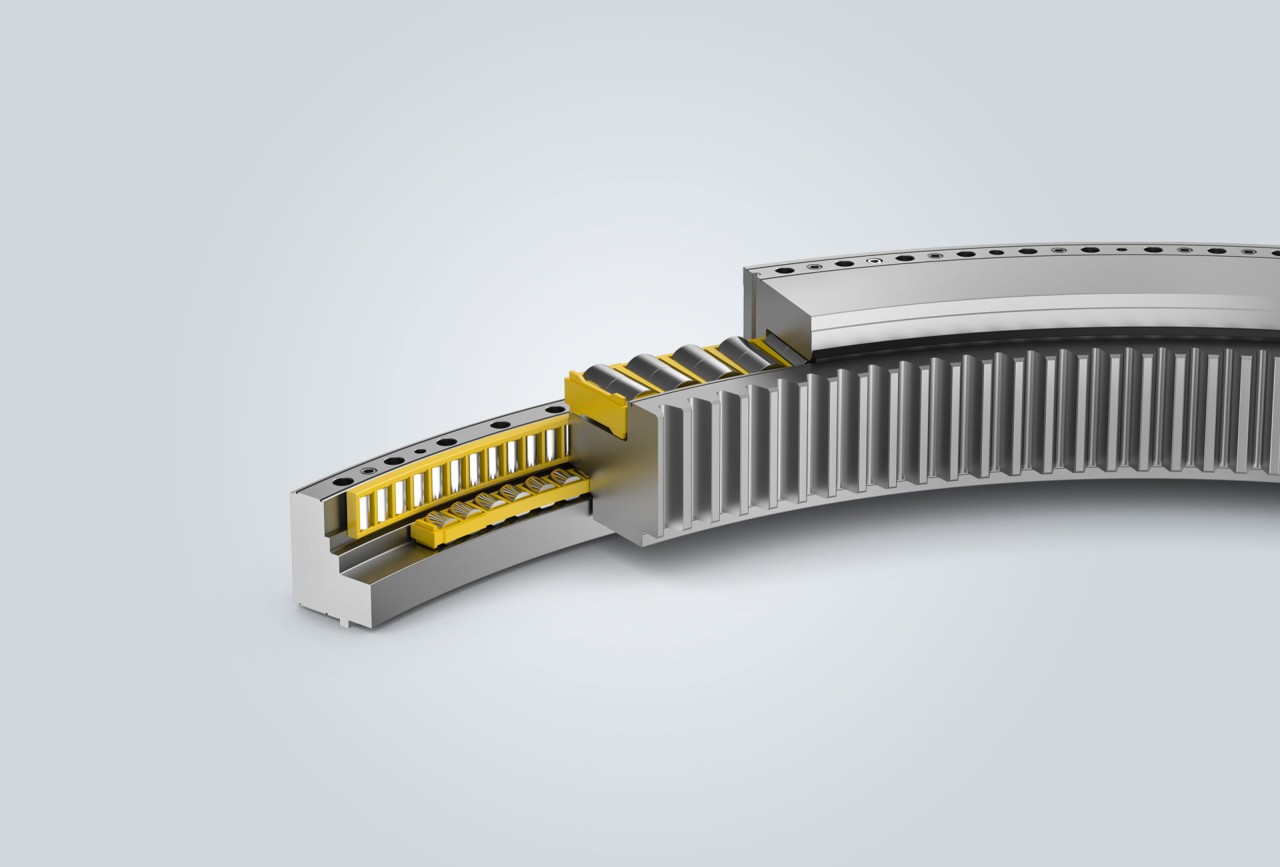

Roller bearing slewing rings for tunnel boring machines are fitted with a preloaded retaining raceway. The cup springs for preloading the raceway ensure that the rolling elements never lose contact with the raceway, thereby guaranteeing optimised wear characteristics.

Lubrication technologies, Automatic Lube Systems Autolube, Auto lube, autolube systems, automatic lube systems, auto greaser

Rothe Erdeslewing bearing

Liebherr roller bearings are suitable for medium to high loads. They are designed as standard in triple-row configurations with two axial and one radial roller raceway. Depending on the case of use, other designs and variants are however also available.

Double-row ball bearing slewing rings are distinguished by their high cost-effectiveness and their robust design. They are used, for example, in crane technology.

Optimum rolling characteristics and ideal power distribution are guaranteed by the layout and design of the tapered rollers. This design is used, for example, as the main bearing in wind turbines or in tunnel boring machines.

Rollingbearing

Bearing designs with bolt connections are used when in the presence of a special adjacent construction. This is often the case with cranes.

Here's the concept: Using a centralized grease pump, a reservoir full of lubricant supplies an electric grease pump which moves grease to a primary distribution block. The grease is then pumped to secondary distribution valves which meter it to specific lubrication points. The auto greasing pump delivers the precise amount of clean lubricant in metered intervals exactly when required.

In addition to customised projects, our portfolio contains a comprehensive standard programme of one-piece Liebherr ball bearing slewing rings.

A lot of companies out there can sell you auto lube, but not everyone can install it and back it up the way we do. Every run of tubing and each stud placement is carefully thought out. Each individual grease point is designed to get the precise amount of grease through metered valves at the nPR+ distribution blocks.

RotekBearing

The combination of roller and ball bearing offers a cost-effective alternative to traditional roller bearing slewing rings. This bearing type is mainly designed for axial loads, and is frequently used in conveyor technology, for example with bucket excavators.

Ball bearings are particularly suitable for applications exerting low to medium loads on the bearings. Usually, polymer spacers are installed between the rolling elements, although bearing designs with steel or brass cages are also available.

The single row tapered roller bearings are mainly used for the main bearing arrangement in wind turbines. Optimum rolling characteristics and ideal force distribution are ensured by the layout and design of the tapered roller bearing.

Tapered roller bearings can be subjected to radial and axial loads. They are suited to high load conditions. The tapered form of the rolling elements ensures optimum rolling characteristics. The play-free bearing mounting makes the tapered roller bearing particularly suitable for the highest precision and accuracy requirements

BRAVO is an electric piston pump with the pumping element operated from a camshaft connected to a reducing gearbox. It can be fitting with up to 3 pumping elements (1 standard) which are available with or without an integrate pre-set bypass (pressure safety valve). The Bravo also has a modular build reservoir that can be supplied in 2, 5, 8-litre capacity. Additionally, a minimum level sensing device is fitted as standard at the base of the unit. As an optional accessory, a remote button with light is available. Bravo is available as both with an integrated automatic control board that controls and monitors the pump and lubrication cycle or a manual version where the pump motor is controlled externally by applying and removing power. The main body of the pump is made from high-performance robust plastic and is compact in size designed to withstand tough environments. The grease version of the Bravo includes a stirrer device with a reservoir wiper that helps to eliminate air present in the grease and facilitate pumping even at lower temperatures.

Rollixbearing

Automatic Lube Systems, Inc takes into consideration your specific application, the way that your equipment moves, and the operating conditions that your machine will see to design a system and custom installation for longevity and durability.

Single-row four-point bearings are used, for example, for the slewing of excavators, the boom movement of tower cranes and as drive elements for large rope winches.

Slewing bearingmanufacturer

Liebherr has developed its own gear cutting machines for the milling of the gear rings. These ensure the best possible gearing results and guarantee optimum precision.

Triple-row roller bearing slewing rings can be fitted according to need with specially-developed seal systems. These can protect the bearing in thrusters, for example, against the penetration of seawater while at the same time preventing the leakage of lubricants.

In addition to customised projects, our portfolio contains a comprehensive standard programme of one-piece Liebherr combined roller and ball bearings.

Bearing designs with bayonet joints are used in the presence of a special adjacent construction. This is often the case with cranes.

On account of their play-free mounting, cross roller bearings offer greater precision than traditional roller bearings. They are used above all in tunnel boring machines and in conveyor technology.

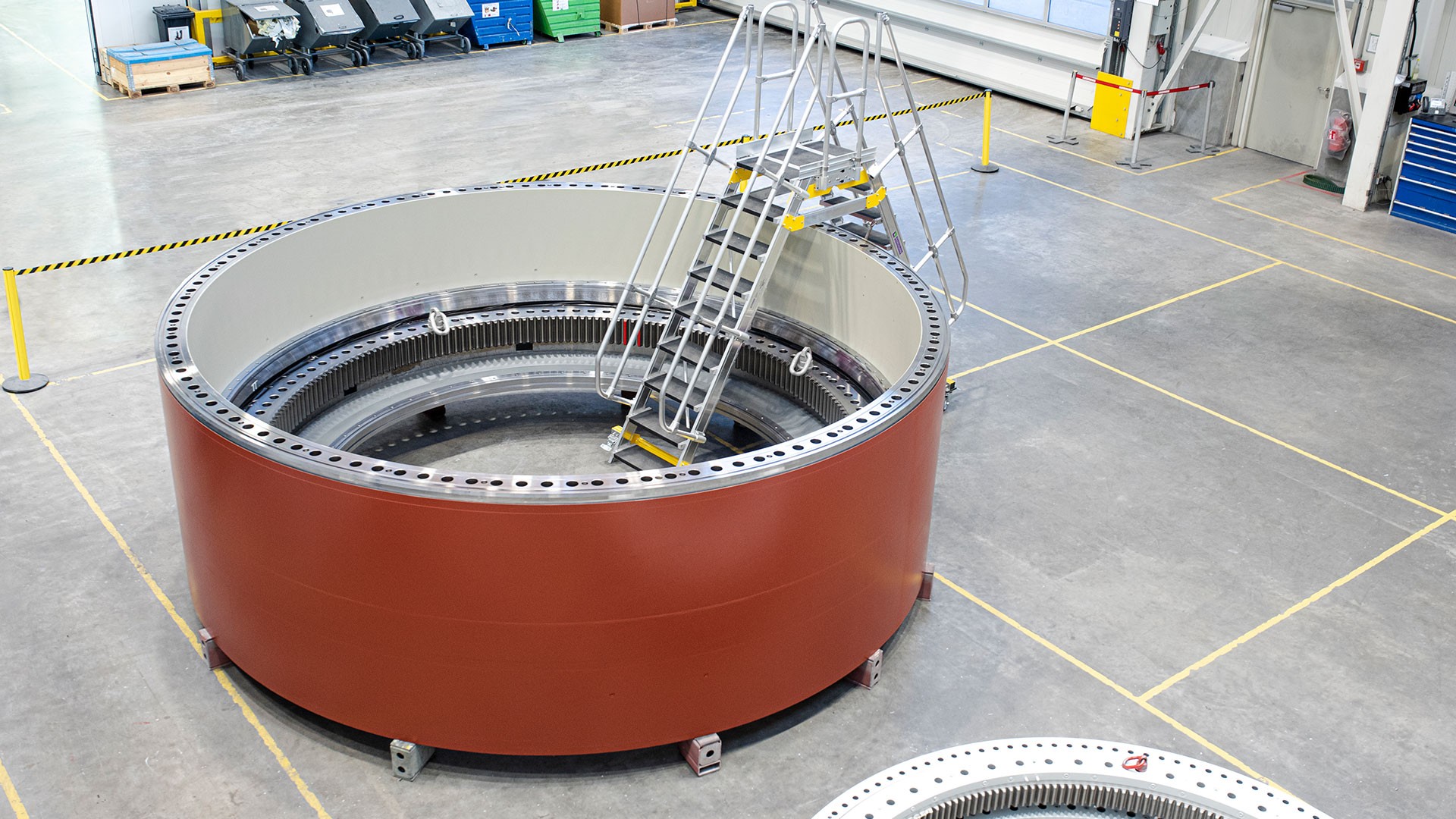

In heavy machines, such as mining excavators, roller bearing slewing rings tend to be used mainly on account of the high loads.

Thrustbearing

In addition to customised projects, our portfolio contains a comprehensive standard programme of one-piece Liebherr roller bearing slewing rings.

Rolling elementbearing

Automatic Lube Systems, Inc uses the best techniques in the business to safeguard our systems. Yes, we use spiral wrap and snakeskin to protect our feed and to-point lines but we also custom fabricate steel guarding when necessary for long system life.

Special forms of seals are always used whenever bearings are exposed to particularly harsh environmental conditions, and protect the slewing bearing, for example, from seawater penetration.

All of our slewing bearings can be manufactured with internal gears, external gears or without gearing. Special gearing, such as helical and worm gears, are also available upon request. The seal concept is also configured for each individual case of use, and takes account of particular environmental conditions, such as particularly saline or dusty air. The bearings can also be coated for extra corrosion protection.

DropsA’s nano-Progressive Replaceable (nPR+) dividers are the ideal solution for grease lubrication applications that require a small and accurately dispensed quantity of lubricant in a compact and solid footprint. Thanks to a patented RigidLock novel interlocking mechanism between the elementsit has the rigidity of a mono-block divider but the flexibility of a modular segmented unit. The nPR+ uses the progressive movement of pistons to allow precise quantities of lubricant to be accurately dispensed to multiple points. The lubrication cycle can be controlled by a single sensor including the DropsA solid state Ultrasensor product. nPR+ uses an innovative rail & lock concept to allow the element to be replaced or reorganized without the need to completely dismantle the assembly. This is an industry first for segmented progressive dividers allowing quick easy modification or replacement of an assembly element without the cost of a separate base porting module. The compactness makes them particularly suitable for use in confined spaces. These metering elements may be used in a variety of system configurations and have different working configurations that make them flexible for use in multiple applications.

Centralized lubrication systems are designed to provide grease for lubricating friction points on industrial and mobile machinery. Such systems considerably reduce the cost of maintaining machinery on which they are installed, eliminating machinery downtime caused by poor lubrication as well as prolonging the life of the machinery in general. Additionally, a centralized lubrication system allows difficult to reach lubrication points to be lubricated at frequent intervals that would otherwise be hard to access under normal conditions.

Liebherr also manufactures gear rings, used for example in rope winch drives or for the yaw adjustment of wind turbines. The gear rings can also be configured in segments according to customer requirements.

Slewing bearingskf

Our goal is to protect our system from any harm. However, should you have an operator damage the system, we make it relativity quick and simple to restore.

Double-row four-point bearings can support significantly higher loads than single-row four-point bearings, for an equivalent diameter. They are used in applications with high loads and restricted installation space, such as for rotor blade adjustments on wind turbines.

Combined roller and ball bearings are designed as standard with a roller raceway (supporting raceway) and a ball raceway (retaining raceway). This makes this type of design particularly suitable for high axial loads and harsh environmental conditions.

Liebherr is one of the world's leading producers of slewing bearings. Our portfolio comprises many different types, manufactured in a wide range of dimensions and designs.

8613869596835

8613869596835