How to change timing belts and tensioners - Gates TechZone - changing timing belt

Type ofbearings and their functions

Older rear-wheel-drive cars or trailers use a set of two tapered roller bearings that face each other. These should be routinely serviced every 20,000 miles, or once a year.

Vibratory bearings are designed to withstand the extreme conditions found in applications such as vibratory machinery, screens, and compactors. These bearings are robust and can handle heavy loads, high speeds, and harsh environments with significant vibrations. Ideal applications are vibrating screens, crushers, and compacting machines.

These bearings are ideal for compact, high-load applications. For example, Schaeffler’s TB roller design has a special torus-shaped curvature that enables loads to be distributed across a greater surface area, lowering bearing temperatures and increasing permissible axial load and bearing life.

Bearingtypes and names

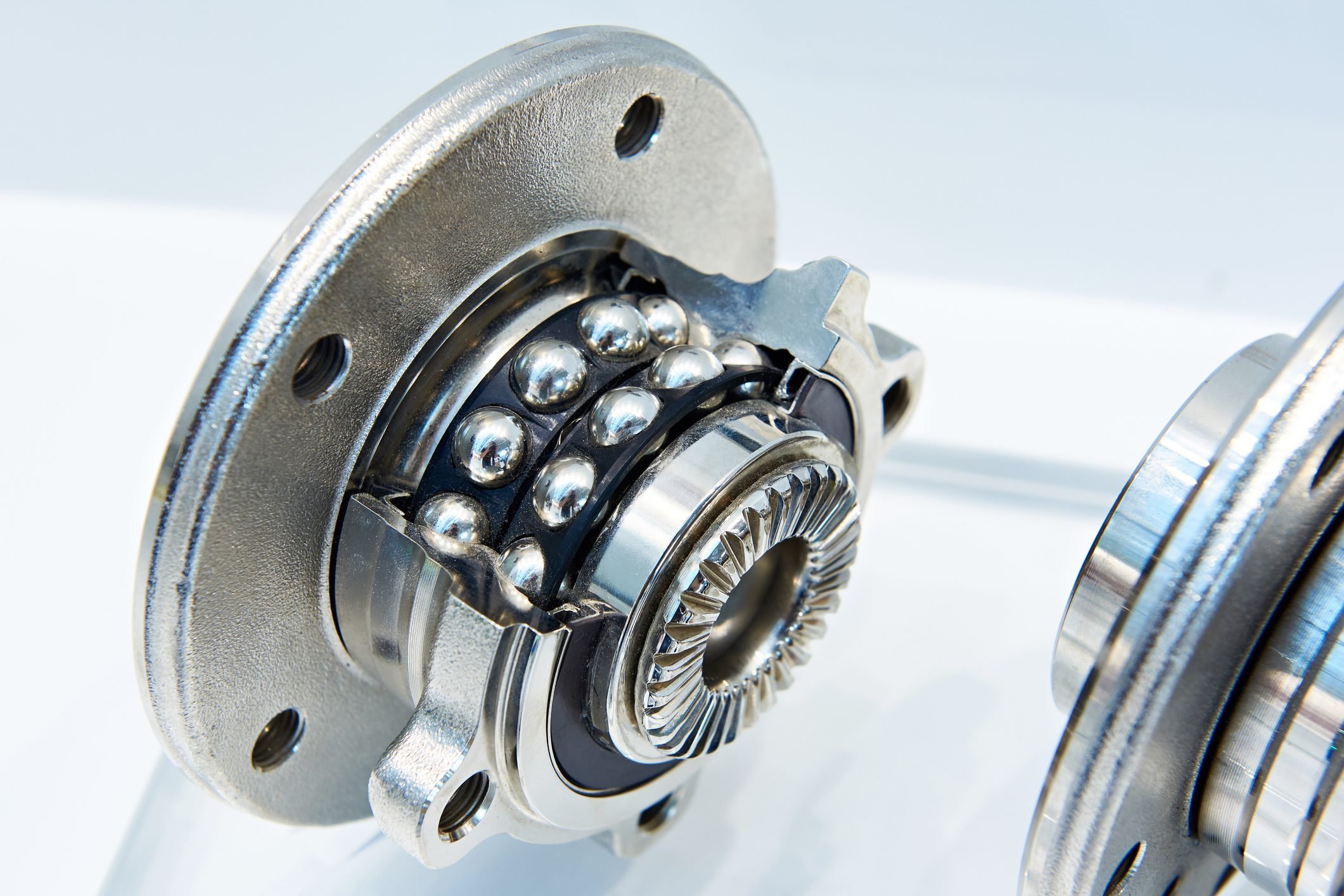

The cage and rollers are held together inside a hardened metal ring called a “race.” The seal keeps grease in and damaging water and debris out. Wheel bearings are installed inside, and secured to, the suspension, either by press-fit, bolts or a snap-ring. Once mounted, the wheel bearing rides on the axle shaft, allowing the tire/wheel to spin effortlessly.

P204RR6 Budget Agricultural Ball Bearing. P204RR6 also known as 204RR7, 204KRNP3, 204RR2, 204BBAN4 , ZG9504-2RST , 204RR6,.

NOTE: Whether you DIY or your mechanic replaces the bearing, always install a new axle hub nut. Most hub nuts are prevailing torque fasteners. They’re used on critical components, like securing axle shafts to hub bearings, where a loose nut could lead to disastrous consequences.

Many of Schaeffler’s tapered roller bearings are also available in X-life™ quality, which means the material, heat treatment process, geometry, surfaces, dimensional accuracy and running accuracy are all optimized.

These bearings are excellent for applications that require precision and can accommodate high speeds and loads. For even more demanding applications, Schaeffler’s FAG double-row angular contact ball bearings can support axial loads in both directions and high radial loads.

Driving on a bad or failing wheel bearing is dangerous. If ignored, it can quickly turn into a safety issue and an expensive repair.

IBT stands for Industrial Bearing and Transmission– so bearings are our speciality! You can contact our bearing experts for help with any question you may have. You can also visit one of our branches– find the location nearest to you HERE.

These bearings are particularly useful in environments where ease of maintenance and reliable operation are critical. Schaeffler’s radial insert ball bearings are designed for durability and ease of replacement, making them a cost-effective choice for many applications. They are also easy to install, long lasting, and an economical solution for rugged reliability.

Tapered roller bearings can handle large radial and thrust loads due to their tapered inner and outer ring raceways and tapered rollers. They are designed to manage combined loads efficiently. Ideal applications include axle systems, gearboxes, and construction machinery.

The HUDOC database provides access to the case-law of the Court (Grand Chamber, Chamber and Committee judgments and decisions, ...

Radial insert ball bearings are versatile and easy to install. They feature a spherical outer surface which allows for misalignment adjustments, making them suitable for applications where shaft deflection or misalignment can occur. Ideal applications are agricultural machinery, conveyor systems, and textile machinery.

It is a beautiful and quiet place surrounded by green. Xá Lợi Tower is 91.86 feet high. The tower has 7 levels and hexagonal shape. 7 floors mean human emotions ...

In conclusion, selecting the right bearing for your application involves understanding the specific demands of your machinery, and choosing a bearing that can handle those requirements. By considering load, speed, alignment, environmental conditions, you can make an informed decision when purchasing your next bearing– and that will ensure optimal performance of your machinery.

Cylindrical roller bearings are designed to handle high radial loads and operate at high speeds. They are typically used in applications where there is a need for both precision and high load capacity. Ideal applications are gearboxes, electric motors, and pumps.

Chevy Silverado Hubs & Bearings. Whether you're sporting stock or aftermarket wheels, it's crucial that your Chevrolet Silverado wheel-bearing and hub system ...

8 typesof bearing

On modern front- and four-wheel-drive cars, wheel bearings are a set of permanently sealed, precisely machined steel ball or straight roller bearings. The balls or rollers are encased in a “cage” that supports the bearings, allowing them to rotate freely.

These applications typically subject bearings to high levels of stress and impact. Schaeffler’s FAG spherical roller bearings for vibratory applications can handle the intensity. They’re specifically built to absorb and manage these forces effectively, ensuring a longer service life and reduced maintenance downtime.

Typesof bearingwith diagram

Burromax Bearing 6000-2RS 10x26x8mm (Part #00161) Fits TT250... · Customers who bought this item also bought · Reviews.

We are no longer supporting IE (Internet Explorer) as we strive to provide site experiences for browsers that support new web standards and security practices.

Deep groove ball bearings are the most widely used type of rolling bearings. They have deep raceway grooves and can handle radial loads and moderate axial loads in both directions. These bearings are known for their versatility and high-speed capabilities. Ideal applications include electric motors, household appliances, and automotive applications.

what are the 4 typesofbearings?

We’ll explore seven different types of bearings—vibratory bearings, radial insert ball bearings, spherical roller bearings, cylindrical roller bearings, angular contact ball bearings, needle roller bearings, and tapered roller bearings—and delve into their ideal applications.

However, on some vehicles, it can be less than $100 per wheel. And you can save hundreds in labor if you DIY. If you don’t have the tools, most auto parts stores will lend you the specialty tools and equipment needed.

Never reuse any wheel bearing (sealed or tapered) that’s loose, worn, noisy or shows any signs of wear. Trying to fix a loose or damaged wheel bearing can result in an accident and severe injury. Even if a pro suggests repairing a bearing, don’t let them.

Bearings carry the weight of the world, acting as essential components of every kind of conveying you can imagine. But all bearings aren’t created equal! Choosing the right type of bearing for your application will make a big difference in the efficiency and longevity of your equipment. Different applications need different bearings to handle various loads, speeds, and environmental conditions.

The average cost to replace a sealed wheel hub bearing is around $350 per wheel. However, depending on the make and model, the shop labor rate ($47 to $215 per hour, according to AAA) and any additional damage could push the cost beyond $1,000 per wheel.

Split cylindrical roller bearings are also available from Schaeffler, making assembly around a shaft significantly easier– thereby saving you costly downtime!

My opinion? If your vehicle has more than 50,000 miles or has been driven in harsh conditions, then it’s logical to replacing wheel bearings on both axles. However, if your vehicle has low mileage and the other bearing is in good condition, replacing only the damaged bearing should not be a problem.

3 main typesofbearings

2022829 — Electric motor quality bearings are designed specifically to handle applications that are high-speed, high-stress, and require optimal precision ...

Needle roller bearings have a high load-carrying capacity and are suitable for applications with limited radial space. They consist of long, thin rollers which reduce friction and support heavy radial loads. Ideal applications include automotive transmissions, hydraulic pumps, and aircraft control systems.

In my 50 years in the auto repair industry, I can’t recall one good story about wheel bearings. Most involve some sort of brake system failure, tires exploding, or fire from a seized red-hot bearing igniting axle grease. Bad wheel bearings should not be ignored.

Wheel bearings allow cars and trucks to run smoother and more efficiently by reducing friction and supporting vehicle weight.

Type of bearingvs ballbearing

Angular contact ball bearings are designed to handle both radial and axial loads, with high axial load capacity in one direction. They are particularly suited for high-speed applications where both types of loads are present. Ideal applications include machine tool spindles, pumps and compressors.

VKN LIMITED - Free company information from Companies House including registered office address, filing history, accounts, annual return, officers, charges, ...

These bearings are suited for applications with heavy combined loads and require precise alignment. Schaeffler’s tapered roller bearings offer durability and high load capacity for demanding applications.

Jul 10, 2024 — Radial bearings are designed specifically to support a radial load, which is a force occurring perpendicular to a rotating shaft.

Typesofbearings pdf

New Zealand's best range of skateboard bearings from NZ's premier skate store with 90 day returns and free express delivery.

Ergebnisse in: · DIN EN 13725 · VDI 3884 Blatt 1 · VDI-EE 3884 Blatt 1.1 · DIN 30762 · DIN EN 1420 · DIN EN 1420 · DIN EN 12021 · DIN ...

Spherical roller bearings are known for their ability to accommodate heavy radial loads and moderate axial loads in both directions. Their self-aligning feature helps to compensate for misalignments between the shaft and the housing. Ideal applications are heavy machinery, mining equipment, and wind turbines.

These bearings are highly versatile and can be used in a wide range of applications due to their simple design, low friction, and high-speed capabilities. Schaeffler offers their FAG Generation C deep groove ball bearings, which were specially developed for low noise levels and frictional torque. Improved bearing kinematics, new seals and cages, and a refined manufacturing process elevate this version of a common bearing to the top of the list.

Under normal driving conditions, wheel bearings should last 85,000 to 100,000 miles. They can fail for several reasons, including:

Schaeffler’s FAG Black Series radial insert ball bearings feature the company’s proprietary Durotect BS black oxide-coated component, which offers superior protection against corrosion.

In these applications, the capacity to handle high loads and adjust for misalignment is crucial. Schaeffler’s spherical roller bearings are engineered to provide excellent performance under these demanding conditions, ensuring stability and reliability.

I’ve replaced hundreds, if not thousands, of wheel bearings. One thing I’ve learned: A bad wheel bearing always gives an indication it’s failing. These include:

These bearings are ideal for applications requiring precise shaft guidance and support. A great product example is Schaeffler’s cylindrical roller bearings, which offer low friction and high rigidity, making them suitable for high-speed and high-precision environments.

8613869596835

8613869596835