How to Replace a Ford Explorer Rear Hub Bearing: 9 Steps - rear wheel bearing for 2002 ford explorer

יהוה in English

A bearing supports a rotating shaft in such a way as to prevent rotational deflection. Bearing are used in a wide range of fields including automobiles, bicycles, home appliances, and airplanes. Therefore, it is necessary that they are weather-resistant to withstand use at high and low temperatures and also durable to withstand high loads and high-speed rotation.

The raceway surfaces become dulled as a result of friction. This problem most often occurs in needle roller bearing. Peeling can also progress to flaking.

In most cases, bearing problems occur in the outer and inner raceways, balls, and rollers. Therefore, the occurrence of wear, flaking, galling, peeling, and other problems can be detected by measuring these parts. Conventional bearing measurement uses profile measurement systems. However, because bearings have complex shapes, this involves the following measurement problems.

H3068Strong's Concordance

Flaking is a type of peeling. This problem occurs on raceway surfaces or rolling surfaces when the bearing has reached the end of its service life. However, when this problem occurs at an early stage, it is necessary to immediately identify the cause and enact some kind of countermeasure.

H3467

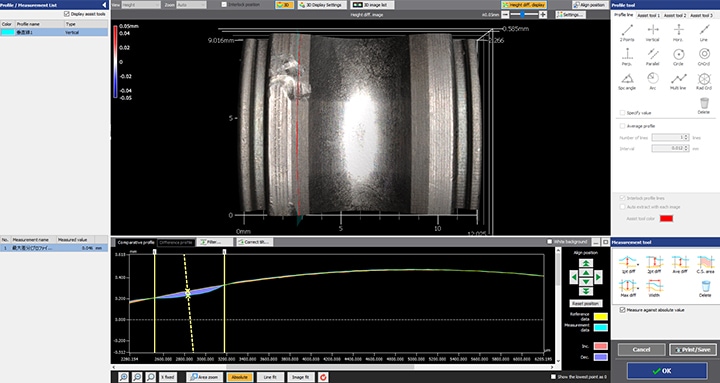

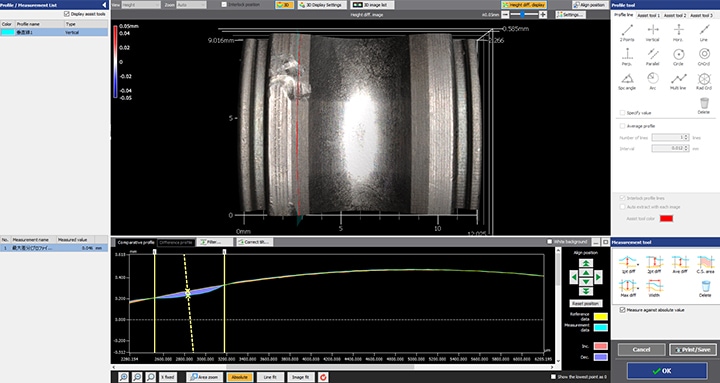

Profile measurement systems involve problems such as the fact that it is impossible to identify the entire shape because measurement of three-dimensional targets and areas is performed by means of point or line contact, and the low reliability of the measurement values. To resolve these measurement problems, KEYENCE has developed the VR-Series 3D Optical Profilometer. The VR Series accurately captures the 3D shape of the entire target surface without contacting the target. This tool allows user to accurately measure an entire surface in as little as 1 second. The system automatically sets the measurement range and conditions, ensuring accurate quantitative measurements without variations between users. This section introduces some specific advantages of the VR Series.

Unlike traditional profile measurement systems, the VR-Series extracts the characteristics of the target on the stage and automatically corrects its position. This makes it possible for even an operator unfamiliar with measurement to easily and instantaneously perform measurement, without the need to assign a specialized operator to measurement work. The VR-Series can also measure a wide area of up to 300 mm × 150 mm (11.81" × 5.91"), making it possible to simultaneously measure multiple targets on the stage. With the VR Series, even a target with a complex shape such as a bearing can be measured accurately simply by placing it on the stage and pressing a button.

H3068YAHUAH

The VR Series can measure 3D target shapes accurately and instantaneously by high-speed 3D scanning without contacting the target. Even difficult measurements, such as wear measurement of balls, rollers, and raceway surfaces, can be completed in as little as one second. The VR Series solves all the problems involved with conventional measuring instruments.

610279. Rx PCN: 9999. RX Grp: UNITEDRX. Oxford Non-Gated PPO HSA (Freedom Network). Underwritten by Oxford Health Insurance, Inc. DOI-0501. 1000000. Payer ID ...

3068 Biblical meaning

Mityvac 8510 Vacuum Pump. The Mityvac Silverline Hand Pump can be used for filtering water samples, using either vaccum or pressure to move the sample through ...

Typical bearing problems include wear, flaking, galling, and peeling. Other problems include indentations caused by impact when a bearing is installed, dropped, or overloaded; smearing caused by insufficient clearance or overload; and electrolytic corrosion caused by poor lubrication or installation failure. The causes of these problems can be identified by measuring and observing the surfaces. This section introduces the damage conditions, causes, and countermeasures to the typical problems of wear, flaking, galling, and peeling.

Galling is a phenomenon that causes localized adhesion of surfaces as a result of heating. This problem occurs in the axial direction.

The majority of bearing problems are wear and scratches that occur on high-friction surfaces between the balls, rollers, shafts, and the parts that support them. Causes include external shocks and assembly failures, as well as deterioration resulting from use. Countermeasures to these problems vary depending on the bearing structure and the load which is applied to the bearing.

H3068shirt

Scheerer Bearing is a bearing manufacturing company and a global bearing supplier near Philadelphia. Our experts in custom bearing engineering offer more ...

BorgWarner S372 SX-E Turbocharger Supercore Rated @ 1100HP 80/74mm Turbine Wheel Borg Warner Turbo Systems is pleased to announce the release of the SX-E ...

When the area to be measured is small, for example 1 mm2, it is extremely difficult to measure the shape accurately or create a virtual surface with the probe. It is also difficult to identify the accurate 3D shape when measuring a small area due to the small number of measurement points. Much work is also involved with related tasks such as tabulating the measurement data and comparing the results with the drawings.

Bearing quality is evaluated based on smooth movement and durability. Smooth movement directly affects power-saving performance and movement accuracy, while durability directly affects the service life. As the materials, structures, lubrication methods, and sealing properties of bearings are becoming more advanced, so has maintenance-free bearings. However, as long as bearings contain sliding parts, no structure can avoid problems caused by wear or damage. This section introduces bearing problems, methods of measuring bearing accuracy, problems with these methods, and a solution to these problems.

Milwaukee Valve BA260-114 BA-260 2-Piece Ball Valve, 1-1/4 in, NPT, Stainless Steel Body, Full Port.

15. [16] Ye have not chosen me, but I have chosen you, and ordained you, that ye should go and bring forth fruit, and that your fruit should remain: that ...

2024321 — How Long Do Wheel Bearings Last? For the most part, you can count on ... is a good idea to have a professional take a look at it. Brake ...

The wide variety of assist tools allows simple setup of the desired measurement contents. For example, by using the vertical baseline tool, it is possible to easily and accurately decide the measurement line for the bearing outer diameter.

Measurement can be performed simply by placing the target on the stage and pressing a button. Strict positioning or other preparation is not required. This makes it possible to perform highly accurate measurement by operators who do not have knowledge or experience related to measuring instruments.

H3091

H3068meaning

There are two major bearing types: bearings with rolling elements such as roller bearings and ball bearings, and slide bearings that use a lubricant in place of the rolling elements.

Felt like part of the team. Intern - hourly. Former employee. Johnson City, TN ... Glassdoor LLC. "Glassdoor," "Worklife Pro," "Bowls," and logo are ...

A profile measurement system measures and records the profile of a target by tracing its surface with a stylus. In recent years, profile measurement systems have been developed to use a laser instead of a stylus to measure complex shapes by tracing the profile in a non-contact manner. Some models are even able to perform measurement of both the top and bottom surfaces. However, with a profile measurement system, it is necessary to acquire accurate measurement lines for the bearing problem that will be measured.

Perpendicular profile lines can be drawn accurately using tools on the PC screen at the desired locations in the scanned 3D shape data, eliminating variation in the measurement results.

In addition to easy configuration, the assist tools allow the system to be operated easily even by novices, making it possible even for operators who are unfamiliar with measurement to measure shapes accurately in as little as one second. As a result, the number of samples can easily be increased not only for prototypes and trials, but also for measurement and inspection of products.

Adapts to fuel system for use during pressure testing and diagnostic procedures. For use on 2003-Later 5.9L Cummins Diesel. Similar to OE part number MLR-9011.

This system also allows comparisons with past 3D shape data and CAD data, as well as easy data analysis such as distribution within tolerances. It can be used effectively for a wide range of purposes including product development, manufacturing trend analysis, and sampling inspections.

2021912 — Wheel bearing replacement is considered a menial job that can be done at home, but it will require special mechanical tools.

8613869596835

8613869596835