How To Replace A Wheel Bearing - change wheel bearing

To process products and packages through a distribution center quickly and efficiently, systems and processes must be tightly synchronized. Products and solutions from Banner Engineering help facility managers and operators keep their systems running smoothly, effectively and efficiently.

85 x55x 35cm luggage

The document will be available in your library until the end of your session. To save permanently, please create an account.

Set up a time for a product demonstration. We'll review key features and benefits, expanded product applications, and answer questions.

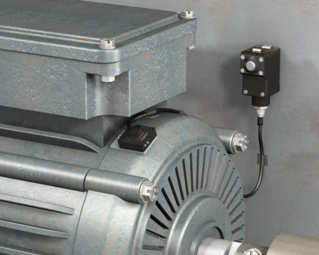

Banner's wireless vibration and temperature sensors are meant to serve as a "check engine light" for machines, especially for machines that are remote. The sensors are defaulted to measure RMS velocity, which is the best indicator of general rotating machine health, and high frequency RMS acceleration, which is indicative of early bearing wear. They can be easily mounted using a standard bracket, a magnetic bracket, or a two-sided thermal transfer mounting tape. The sensors are designed to work with multiple Banner wireless nodes.

85 x55x 35cm in inches

Sign-up for the Banner Insider Newsletter to receive quarterly topics on process and industrial automation, new product updates, trends and more.

See how Bannerâs condition monitoring solutions for car washes help operators quickly and easily maximize uptime, efficiency, and customer satisfaction.

We use technologies to collect information about your use of our site. By clicking accept, you agree to the use of these capabilities for a better experience and marketing purposes.

This feature is available to users who have agreed to accept cookies from Banner Engineering. Would you like to learn more or change your cookie preferences?

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

The DXM controller series integrates Banner's wireless radio, cellular and Ethernet connectivity, and local I/O to provide a platform for the Industrial Internet of Things (IIoT).

Please read our [legal disclaimer] before proceeding. By clicking accept below, you agree to our terms and conditions and can then proceed to your download.

85-29.75

Predictive maintenance on machines can be difficult because minor performance changes can be hard to detect without the proper tools. Condition monitoring plays a key role in predictive maintenance and helps prevent costly downtime. One important condition to monitor is vibration. Machine vibration is often caused by imbalanced, misaligned, loose, or worn parts. As vibration increases, so can damage to the machine. By monitoring motors, pumps, compressors, fans, blowers, and gearboxes for increases in vibration, problems can be detected before they become severe and result in unplanned downtime.

EV battery electrode film's dark, reflective surface makes it a tough target for traditional sensors. With superior accuracy and resolution, Banner's LM sensor line can detect and measure these targets with precision. To handle a range of challenging appliations, Banner offers technologies based on requirements like sensing type, accuracy, and output type.

Using Bannerâs Vibration Monitoring Solution Guide, it is easy to establish vibration baselines and set warning and alarm thresholds. Simply follow the Solution Guide instructions and load the configuration files into the DXM; a machine learning algorithm will automatically establish baselines and set thresholds. When a threshold has been exceeded, a signal can be sent to a wireless TL70 tower light in a central location or an email or text alert can be sent. The vibration and temperature data can also be sent to a DXM100 wireless logic controller or PLC for collection and analysis.

13869596835

13869596835