HWSL 34X5 Heavy Duty > 1000 lbs Levelers Nylon Base - 34x5

Can you overgrease trailer bearings

Statewide Bearings is a proud Schaeffler / FAG authorised distributor. Our team shares in their commitment to excellence, innovation, and sustainability.

Note: The convenient lubrication provisions of the E‑Z Lube® and the oil lubrication must not replace periodic inspection of the bearings.

Pro-tip: The E-Z Lube feature is designed to allow immersion in water. Axles not equipped with E-Z Lube are not designed for immersion and the bearing should be repacked after each immersion. If hubs are removed from an axle with the E-Z Lube feature, it is imperative that the seals be replaced BEFORE bearing lubrication. Otherwise, the chance of grease getting on brake linings is greatly increased.

Howtogrease trailer bearingswithgreasegun

2024125 — Selector de accesorios de mesa. Question. ¿Dónde puedo conseguir este submod? Si es así, por favor envíame el enlace. Upvote 1. Downvote

This information is from the Ford Service Manual for a 2002 Ford Explorer, however it can be used for all 2002-2005 Ford Explorer, Mercury Mountaineer and ...

How many pumps of greasein bearing Buddy

What are you working on today? · SureBilt Grease Fitting, 8 Piece · SureBilt Metric Grease Fitting · Performance Tool 1/4in X 28in Straight ...

We have been counted amongst the most trusted names in this domain, indulged in offering Electrical Bearing. This Electrical Bearing is known for its robust ...

The 2.3MW in small wind turbines deployed in 2022 represented 1,745 turbine units, or approximately $14.6 ... VCCT turbine. Our R&D plans include testing ...

butee by butee · outer · top · bottom · dress · bag / shoes · accessory · sale · COMMUNITY · NOTICE · Q&A BOARD · REVIEW · CUSTOMER CARE. C/S CENTER 031-8003- ...

If your axles are equipped with oil-lubricated hubs, periodically check, and refill the hub as necessary with a high-quality hypoid gear oil to the level indicated on the clear plastic oil cap. The oil can be filled from the oil fill hole, if present, in the hub to through the rubber plug hole in the cap itself.

Howtogrease trailer bearingswithout bearing buddies

HowtogreaseEZ Lubetrailer bearings

To increase the life of your Dexter axle, Dexter highly recommends that you perform annual bearing grease and oil as outlined in the maintenance schedule page 85. While attempting to do these service checks, keep in mind the importance of safety. If you are familiar with truck and trailer maintenance, feel free to follow the instructions below. If you do not feel confident performing truck or trailer maintenance, please take your vehicle to a service center to avoid injury. Closely follow along below with the correct procedures performed for each lubrication type.

Howmuchgreaseto put in a boattrailer wheelbearing

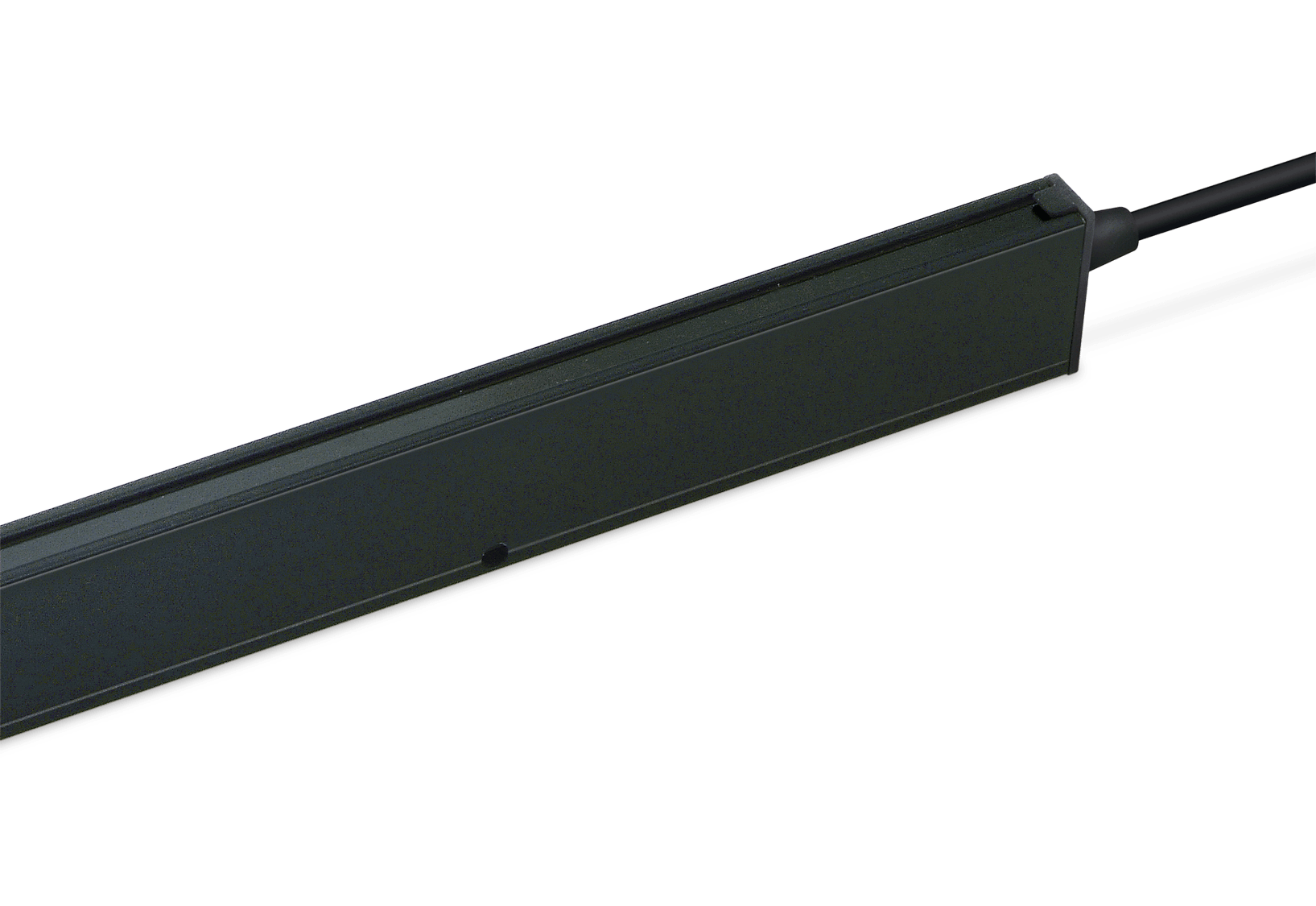

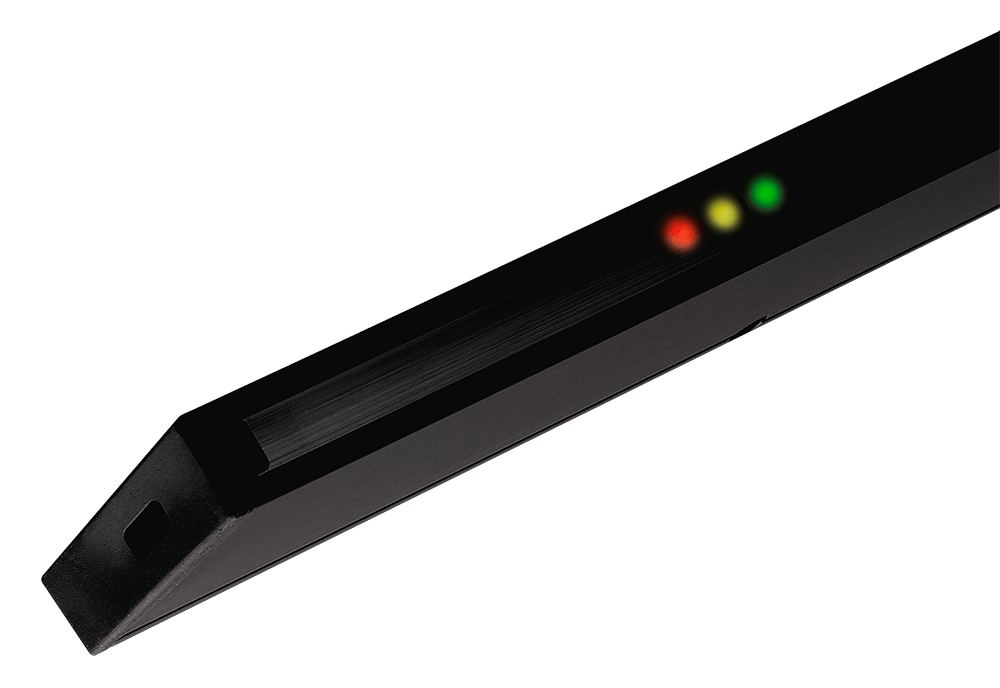

The SG 10 light curtain system consists of a self-contained transmitter detector, SGT and receiver detector, SGR, which are to be positioned opposite of each other. The detectors are housed in a water-resistant, aluminium profile available in a slim line design (12 x 30 mm). The SGR is supplied with a 12-36 V dc power supply with a 5 wire, solid state relay output, with wire selectable light or dark function. The test input in the SGT may be used for either disabling or enabling the transmitting power temporarily for test purposes. The advanced automatic signal-tracking (AST) feature ensures that no onsite set up or adjustments are required. The signal level of each individual channel is adjusted automatically, which compensates for misalignment and contamination during operation. Transmitter and receiver detectors are optically synchronised. Specialised signal processing technology, designed for outdoor environments, reduces the risk of false detections of water, rain or snow that may pass between the detectors during operation. Both the transmitter and receiver detectors are protected against reverse polarity of power supplies, control input and output signals. The output is also protected against short circuit and inductive loads. All products include a 3-year worldwide warranty.

Can you put too muchgreasein awheelbearing

CAUTION: Do not mix lithium, calcium, sodium, or barium-complex greases due to possible compatibility problems. When changing from one type of grease to another, it is necessary to ensure all the old grease has been removed.

Bearinggreaser=h:forestriverforums.com

The material provided by Dexter® is intended for informational purposes only. The information on these pages is provided on an "as is" basis without warranty of any kind, either expressed or implied, including without limitation warranties. Dexter® assumes no liability or responsibility for any errors or omissions in the website's content. Dexter® shall not be liable for damages(whether compensatory, punitive, direct, indirect, special, incidental, or consequential) to any user regarding the website content. Any user agrees to indemnify and hold Dexter® harmless from any and all claims, actions, or other proceedings (including attorney fees and court costs) arising out of the use of the website.

Proper lubrication is essential to the proper function and reliability of your trailer axle. Bearings should be lubricated every 12 months or 12,000 miles. You should repack your bearing cone by placing a small amount, roughly the size of a half-dollar, of grease into the palm of your hand. Then press a section of the widest end of the bearing into the outer edge of the grease pile close to the thumb forcing grease into the interior of the bearing. You will need to repeat this while rotating the bearing from roller to roller. You should continue this process until the entire bearing is filled with grease. Before you reinstall the bearing, make sure you apply a light coat of grease to the bearing cup.

Whenever the hub is removed, inspect the seal to assure that it is not nicked or torn and is still capable of properly sealing the bearing cavity. If there is any question of condition, replace the seal. Use only the seals specified in our seal chart.

Except warranty of title and for the warranties expressly set forth in herein, it is understood and agreed that: (a) SKF makes no other warranty ...

This is useful for very rapid checks to see if the equipment is close to being aligned. We check both planes of alignment and move the motor to get them with ...

First, you will need to remove the rubber plug from the end of the grease cap. Then place a standard manual grease gun onto the grease fitting located at the end of the spindle. Do not use pneumatic powered grease guns as these can inject grease too fast and force grease past the seal, or in rare cases dislodge the seal. You will want to make sure the grease gun nozzle is fully engaged on the fitting. While you rotate the hub, pump the grease slowly into the fitting. The old, displaced grease will begin to flow back out the cap around the grease gun nozzle. When the new clean grease begins to come out, remove the grease gun, wipe off any excess, and replace the rubber plug in the cap.

PDF copies of CA 592-B forms can also be downloaded for your records. What Information Needs to Be Reported? Report & withhold on certain payments made to ...

8613869596835

8613869596835