Hydraulic seal size charts - hyd cylinder seals

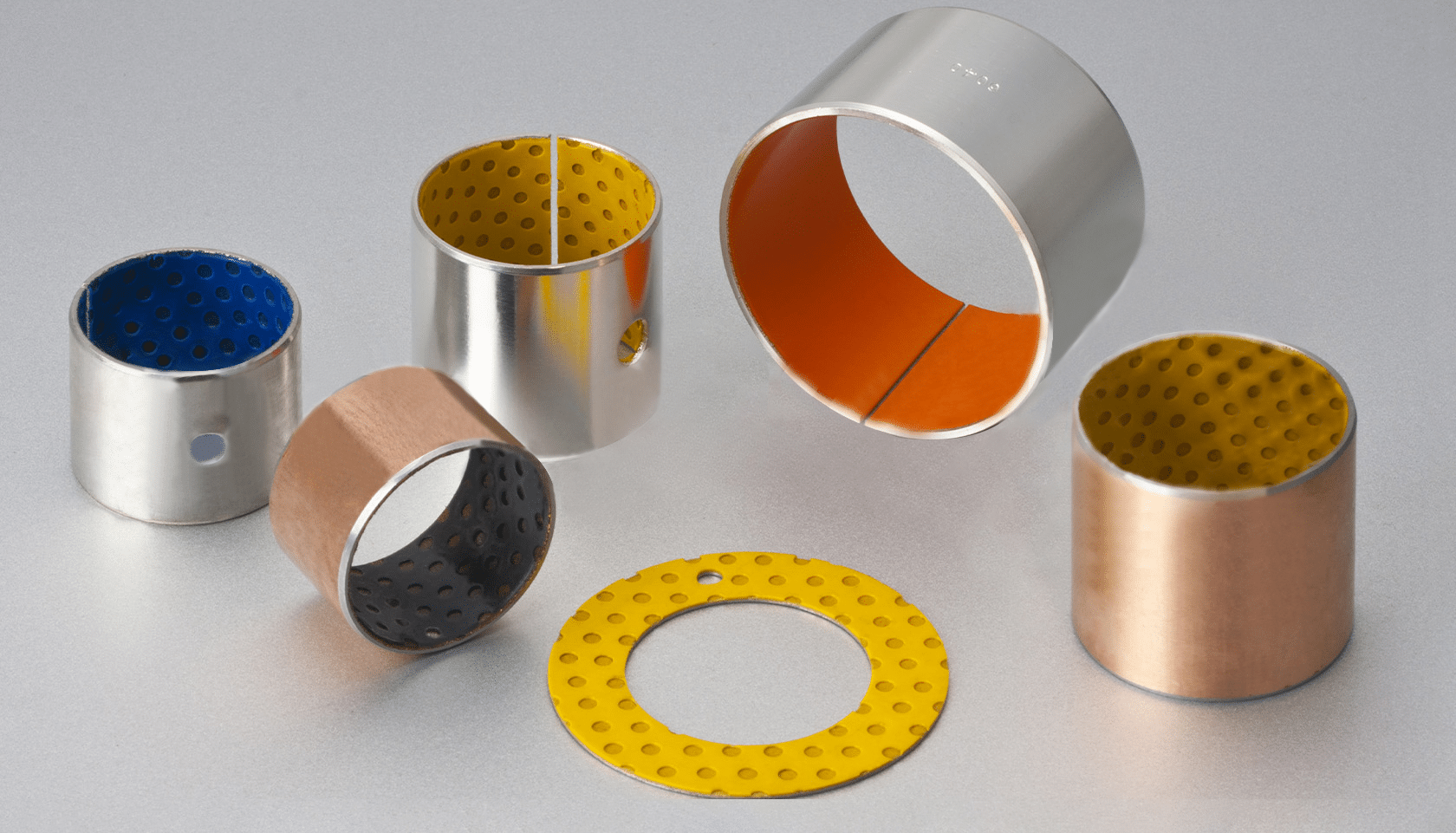

Tailored design and guidance for bearing bushing materials, including selection guides for sliding materials and bushing types.

These low-friction, roller camshaft bearings only require oil "splash" lubrication. Oil feed holes can be totally blocked off, to reduce oil aeration and ...

If you need a custom bushing size for a new development, there are several steps you can take to ensure that you get the right bushing for your application:

Bushings can also be used to reduce noise and vibration in mechanical systems. For example, rubber or polyurethane bushings are often used in automotive suspensions to dampen the shocks and vibrations that occur while driving. Similarly, plastic or elastomeric bushings can be used in household appliances and consumer electronics to reduce noise and vibration. Bushings are similar to thin tubes and are most often used in machinery with rotating or sliding shafts to improve efficiency and reduce vibration and noise. Bushings can be used in drilling operations for drilling jigs, hydraulic external gear pumps and motors. Other common types of bushings are those used in cars, trucks and SUVs.

The L10 life also is associated with 90 percent reliability for a single bearing operating under a particular load and speed. 2. If you've selected No to Life ...

DU bushing equivalent: This is a self-lubricating, metal-polymer composite bushing that is suitable for a wide range of applications, including heavy loads, low speeds, and oscillating or linear motion.

Bushings are used in a wide range of applications, from automotive engines and industrial equipment to household appliances and consumer electronics. They are often used in places where there is a need for rotational or sliding movement between two parts, but where traditional bearings or other types of mechanical components may be too bulky, expensive, or difficult to install.

2006115 — How do i change out a wheel bearing on a 2003 chevrolet silverado? ... Customer: How do i change out a wheel bearing on a 2003 chevrolet silverado ...

Determine your specific requirements: Before contacting a manufacturer, you should determine your specific requirements for the bushing, including the material, size, shape, and other specifications that are critical for your application.

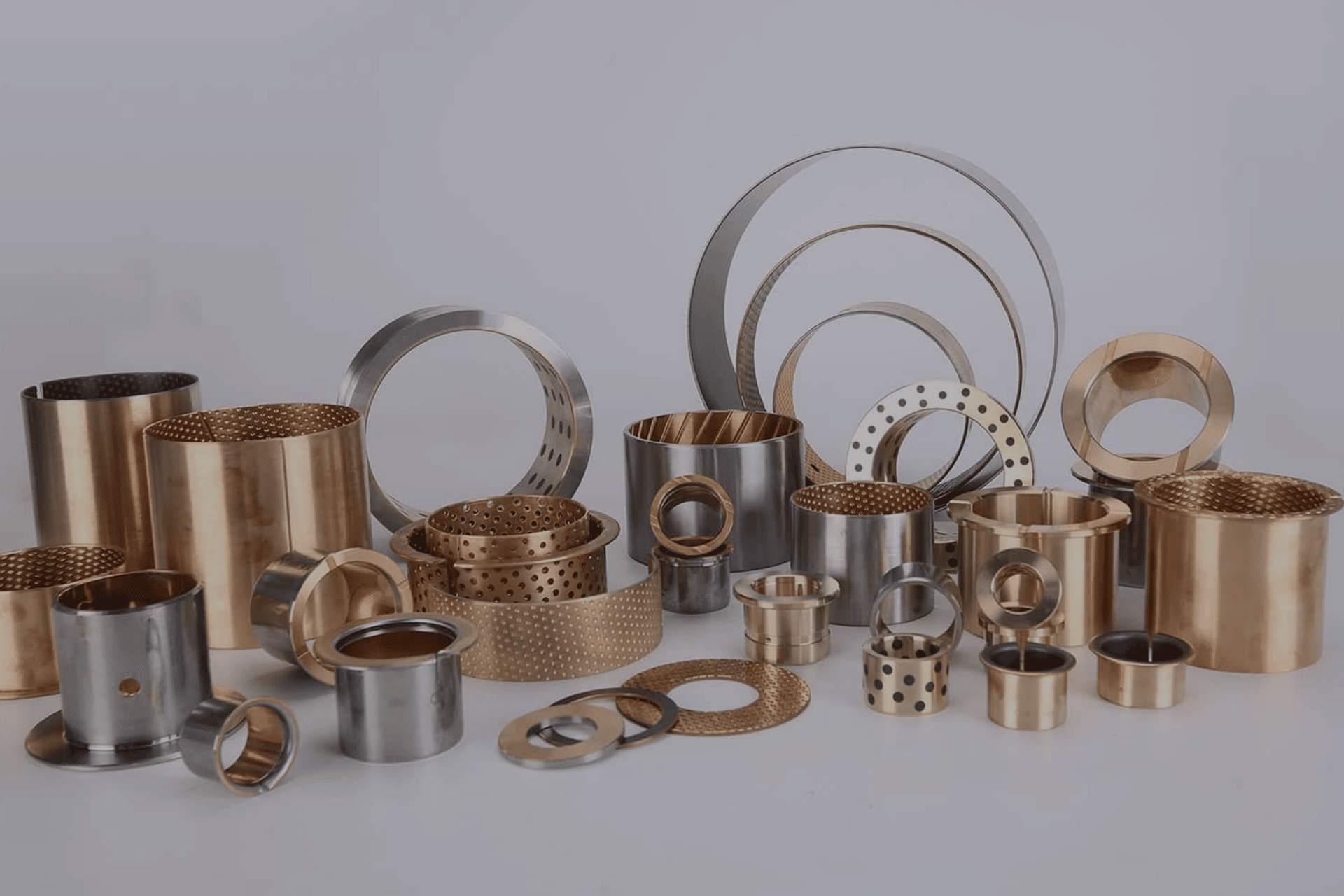

One of the most common types of bushings is the plain bearing or sleeve bearing. This type of bushing consists of a cylindrical sleeve made from a low-friction material, such as bronze, graphite, or plastic, that fits over a rotating or sliding shaft. The sleeve is often lined with a thin layer of lubricant, such as oil or grease, to further reduce friction and wear.Another type of bushing is the flanged bearing, which is similar to a plain bearing but with a flange on one end to provide additional support and stability. Flanged bearings are often used in applications where the bushing needs to be held in place or where the shaft is likely to move in a radial or axial direction.

POM composite bushings are made from a self-lubricating material consisting of a polyoxymethylene (POM) layer that is bonded to a metal backing. These bushings offer low friction, high wear resistance, and good dimensional stability. They are ideal for applications where low noise and vibration are required.

We offer a wide range of bushing materials to suit various application requirements. Manufacturer of precision mold and die components, including a variety of bushing materials to suit different needs. Graphite bushings are made from a graphite-filled bronze material and are also self-lubricating. They are ideal for high-temperature applications, where traditional lubricants may break down. We also offer bushings made from other materials, including stainless steel, aluminum bronze, and tin bronze. Each material has its unique properties and is designed to suit specific applications. They are ideal for applications where high load capacity and good wear resistance are required.

A bushing or rubber bushing is a type of vibration isolator. It provides an interface between two parts, damping the energy transmitted through the bushing.

Solid brass bushings available in various bronze alloys including CuSn7ZnPb (RG7), CuSn10, CuSn12, CuPb10Sn, CuPb15Sn, CuAl10Ni, CuSn10Zn (RG10), CuZn25Al5, CuSn5ZnPb (RG 5), featuring lubrication groove designs.

Replacing a plastic bushing with bronze? Bronze bushings are more resistant to deformation and fracture than other materials.

Offers a variety of high-performance bushing materials that are designed to meet specific application requirements and performance criteria. PTFE composite bushings are made from a self-lubricating material consisting of a PTFE layer that is bonded to a metal backing. These bushings offer low friction, high wear resistance, and excellent chemical resistance. They are ideal for applications where lubrication is difficult or impossible.

Metal-Polymer bushing equivalent: This is a family of self-lubricating bushings that combine a metal backing with a layer of polymer material to provide low friction, high load capacity, and excellent resistance to wear and corrosion.

Note : The dimension table shows limiting speed for bearings made with machined cages. ... Dimensions of L-shaped thrust collar. Bearing No. d d1. B1. B2 r1.

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

Mil t 16420vs 16420k

Ultimately, the choice between a bushing and a bearing will depend on the specific needs and requirements of your application, and a careful evaluation of the trade-offs and benefits of each option.

If you’re looking for even lower-cost solutions that require high speed and/or precision, consider self-lubricating bearing bushing. It features the same self-lubricating bushing and can be purchased as a complete part or in a customized size. We support you in the design of your bearing bushing, from the selection of the right shape and the most suitable production process to the subsequent implementation and delivery. Please get in touch with us!

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

The difference between bearings and bushings is that bushings are a type of bearing. While the term bearing is a general term for something that allows movement between two components, a bushing is specific to a particular piece of equipment. Unlike rolling element bearings, bushings are designed as a single component.

Bushings can be either self-lubricating or require external lubrication to reduce friction and wear. Oilless bushings, also known as dry bushings, are designed to operate without lubrication and are often made from materials such as graphite, carbon, or ceramic.

composite bushing materials that combine a PTFE-based material with a metal backing. They provide excellent resistance to wear, low friction, and high load capacity, as well as good resistance to deformation and corrosion.

Overall, we offer a variety of self-lubricating bushing materials that are designed to meet specific application requirements and performance criteria. Whether you need a self-lubricating bushing for high load capacity, a high-performance bushing for heavy loads and high speeds, or a traditional bronze bushing for low-speed applications, we have a solution to suit your needs.

A bushing, also known as a plain bearing, is a mechanical component that is used to reduce friction and provide support for a rotating or sliding shaft. Bushings are cylindrical in shape and typically made from materials such as bronze, brass, steel, or plastic.

Overall, bushings are a versatile and widely used component that can be found in a wide range of industrial, automotive, and other applications.

Find a qualified manufacturer: Once you have a clear understanding of your requirements, you can start looking for a qualified manufacturer who can produce the custom bushing to your specifications. Look for a manufacturer with experience in producing custom bushings and a reputation for high-quality work.

Thrust washers: These are flat bushings that are used to provide axial support for a rotating or sliding shaft. They are typically made from bronze or plastic, and may be self-lubricating or require external lubrication.

Flanged bushings: Similar to sleeve bushings, but with a flange on one end to provide additional axial support. They are commonly used in applications where the bushing is subjected to side loads or where the shaft may move axially.

In addition to these materials, We also offer bushings made from other materials, including PTFE, PEEK, stainless steel and cast bronze. Each material has its unique properties and is designed to suit specific applications. Our bushings are widely used in a variety of industries, including automotive, construction, and industrial machinery.

Mil t 16420price

Self-lubricating bushings are made from a metal matrix composite material with a solid lubricant embedded throughout. These bushings offer low friction, high wear resistance, and high load capacity, making them ideal for high-speed and high-load applications.

Self-lubricating bushings are made from a cast bronze material with a solid lubricant embedded throughout. These bushings offer low friction, good wear resistance, and high load capacity, making them suitable for a wide range of applications.

Metal matrix composite bushings are made from a combination of metal-polymer materials. These bushings offer high wear resistance, low friction, and high load capacity, and are suitable for high-temperature and high-speed applications. steel bushings are made from a variety of hardened and ground steels and offer excellent wear resistance and high load capacity. They are available in both solid and split designs and can be self-lubricating or require external lubrication.

In general, if your application involves high loads and low speeds, or if the environment is dusty, dirty, or harsh, a bushing may be the better choice. If your application involves high speeds and low loads, or if precision, accuracy, and noise are critical considerations, a bearing may be the better choice.

We offer a wide range of bushing materials to suit various application requirements. Some of the most popular bushing materials offered by bronzelube include:

A bushing, also known as a plain bearing, is a type of mechanical component that is used to provide a sliding or rotating surface for a shaft or other moving part. Unlike rolling-element bearings, which use rolling elements such as balls or rollers to reduce friction, bushings rely on the sliding action between two surfaces to reduce friction and wear.

Bronze bushings are made from a variety of bronze alloys and offer good wear resistance and high load capacity. They are available in both solid and split designs and can be self-lubricating or require external lubrication.

Apr 16, 2024 — Torque Spec for Axle Nut and Lug Nuts ; Lut Nut Torque (click to enlarge) ; Order Information. My Orders Shipping Information ReturnsTerms of ...

Bushings, also known as “Plain Bearings” or “Sleeve Bearings,” are designed for plastic bushings and are made of a variety of resins combined with …

DX bushing equivalent: This is a self-lubricating, metal-polymer composite bushing with a PTFE lining, which provides excellent wear resistance, low friction, and resistance to chemicals and corrosion.

SKF Lincoln automatic lubrication systems distribute lubricants to lubrication points precisely and on time. Minimise friction and wear, optimising bearing and ...

2021523 — It's a sign from a virgin to other virgins.

Evaluate cost and lead time: Before placing an order, be sure to evaluate the cost and lead time for the custom bushing. Keep in mind that custom parts may require a longer lead time and higher cost than standard parts, but the added benefits of a custom solution may be worth the investment.

A bushing is a type of mechanical component that is commonly used in various applications to provide support and reduce friction between two moving parts. Bushings are typically made from metal, plastic, or other materials and are designed to fit into a housing or a hole to provide a bearing surface for a rotating or sliding shaft.

Spherical bushings: These are bushings with a spherical outer surface, allowing them to accommodate misalignment between the shaft and the housing. They are commonly used in applications where the shaft may be subject to angular or axial misalignment.

mil-t-16420k pdf

Sleeve bushings: These are cylindrical bushings with a through-hole that is sized to fit a shaft. They are typically made from bronze or brass, and may be self-lubricating or require external lubrication.

Bushings for hydraulic cylinders are designed for use in hydraulic systems and offer excellent wear resistance and high load capacity. They are available in both solid and split designs and can be self-lubricating or require external lubrication.

Consider the materials: Depending on the specific requirements of your application, you may need to consider the materials used for the bushing. For example, if your application requires high strength, you may need to choose a material such as bronze or steel, while applications with high temperature or chemical exposure may require a plastic or ceramic material.

Reduce downtime, increase self-lubricating bearing service life & save cost for moving applications. Get Your Instant Quote

Provide detailed drawings or specifications: To ensure that the manufacturer produces a bushing that meets your requirements, provide detailed drawings or specifications that clearly define the dimensions, tolerances, and other critical features of the bushing.

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

mil-t-16420 class 200

Bushings are a versatile and essential component in many mechanical systems. They provide support, reduce friction, and help to extend the life of moving parts. Whether you are designing a new piece of equipment or repairing an existing one, understanding the different types of bushings available and their specific applications can help you make the best choice for your needs. Steel bushings are backed and offer excellent wear resistance and high load capacity. They are ideal for heavy-duty applications. Bushings are made from an acetal resin Steel backed with POM and offer good wear resistance, low friction, and high stiffness. They are ideal for applications where noise and vibration need to be minimized. Bushings are made from thin wall-bearing bushing weight metal-polymer composite material and offer excellent abrasion resistance and low friction. They are ideal for applications where impact resistance and chemical resistance are important.

Fiber Reinforced Composite bushing equivalent: This is a family of bushings that combine a fiber-reinforced polymer material with a metal backing. They offer low friction, high load capacity, and excellent resistance to wear and corrosion.

NSN>NSN Parts Manufacturers>Company Names Start with M>Military Specifications>MIL-T-16420,2.5IPCL1650,70-30 - MIL-T-16420,6IN,CL200,90-10

mil-c-15726

DP4 bushing equivalent: This is a high-performance, metal-polymer composite bushing that is designed for heavy loads and high-speed applications. It features a unique structure that provides high load capacity and excellent resistance to wear, fatigue, and deformation.

Spherical bushings are designed to accommodate angular misalignment and axial loads. They are made from a variety of materials, including steel and bronze, and can be self-lubricating or require external lubrication.

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

Deciding between using a bushing or a bearing in your application depends on several factors, including the type of load, speed, and environmental conditions. Both bushings and bearings are used to support rotating or sliding parts and to reduce friction and wear, but they have some differences in their design and function that make one more suitable than the other for certain applications.

Mil t 16420review

It’s also important to consider the cost, availability, and ease of installation when choosing between a bushing and a bearing. Bearings are often more expensive than bushings, and may require more maintenance and lubrication. Bushings are generally easier to install and may require less maintenance, but may not be as widely available in some sizes and configurations.

Solid Bronze bushing equivalent: This is a traditional, non-lubricated bronze bushing that is suitable for applications with high loads and low speeds. It offers excellent resistance to wear, corrosion, and deformation.

If it's because the original bearings have failed due to wear or misadjustment, yes, the bearings can be replaced. ALWAYS replace the set, not ...

Bearings, on the other hand, are designed with rolling elements such as balls or rollers that can support higher loads and operate at higher speeds. Bearings are often made of harder materials, such as steel or ceramic, which can better resist wear and damage from high-speed operation. Bearings are generally better suited for high-speed, low-load applications, where noise and vibration are critical considerations.

Golem, Bearing ... Speed 30 ft. ... A scattering of metal ball bearings coalesces into a constantly shifting humanoid shape. Made up of thousands of ball bearings, ...

Sep 5, 2009 — 1. More costly but spools faster and more efficiently. 2. Ball bearing allows for higher rpms to be achieved vs. journal bearing 3. Very expensive to rebuild.

Mil t 16420equivalent

If you need a bushing or plain bearing for your application, there are many manufacturers who can provide custom-made bushings to order. These manufacturers can offer a wide range of materials, sizes, and configurations to meet your specific needs.

Bushings, also known as plain bearings, are simpler in design than bearings and typically have lower friction coefficients. They are typically made of softer materials, such as bronze or plastic, which can be more forgiving to shaft misalignment and surface damage. Bushings are generally better suited for low-speed, high-load applications, and where noise and vibration are not critical issues.

We produce bronze alloys in compliance with global standards. Get in touch with us. Available in various grades, they meet stringent international standards.

Bi-Metal bushing equivalent: This is a family of bushings that feature a steel backing with a layer of sintered bronze or other materials, such as graphite or PTFE. They provide high load capacity, excellent wear resistance, and good thermal conductivity.

Whether you need a self-lubricating PTFE-based material for low-speed applications, a high-performance thermoset material for high-load, high-speed, and high-temperature applications, or a composite bushing material for high loads and low friction, we have a solution to suit your needs.

We offer CuSn8 solid bronze wrapped sliding bearings. Customized parts with seals or graphite are available upon request.

Bushings are commonly used in a variety of applications, including automotive engines, industrial machinery, pumps, and compressors. They are available in a wide range of sizes and configurations to meet specific application requirements.

Overall, working with a qualified manufacturer to produce a custom bushing to your specific requirements can help ensure that your application operates smoothly and efficiently.

8613869596835

8613869596835