Hyundai Sonata Front Wheel Bearing Replacement Costs - hyundai sonata front wheel bearing

Older rear-wheel-drive cars or trailers use a set of two tapered roller bearings that face each other. These should be routinely serviced every 20,000 miles, or once a year.

Chevyengine bearing clearance

Greasing Trailer Wheel Bearings ... Immerse the bearings and spindle nut in kerosene for 10 minutes. Then, wipe them down with brake cleaner. Simply push new ...

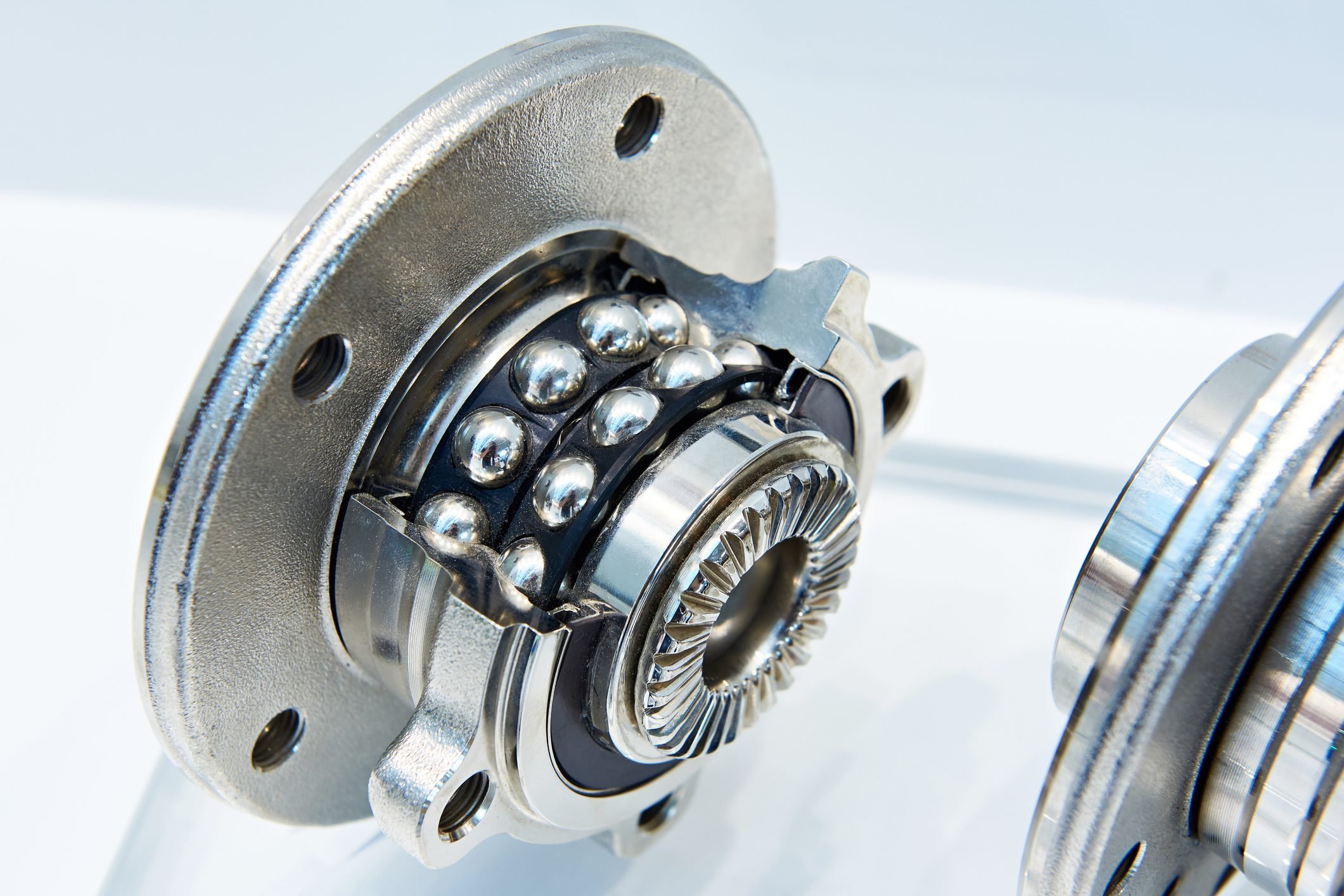

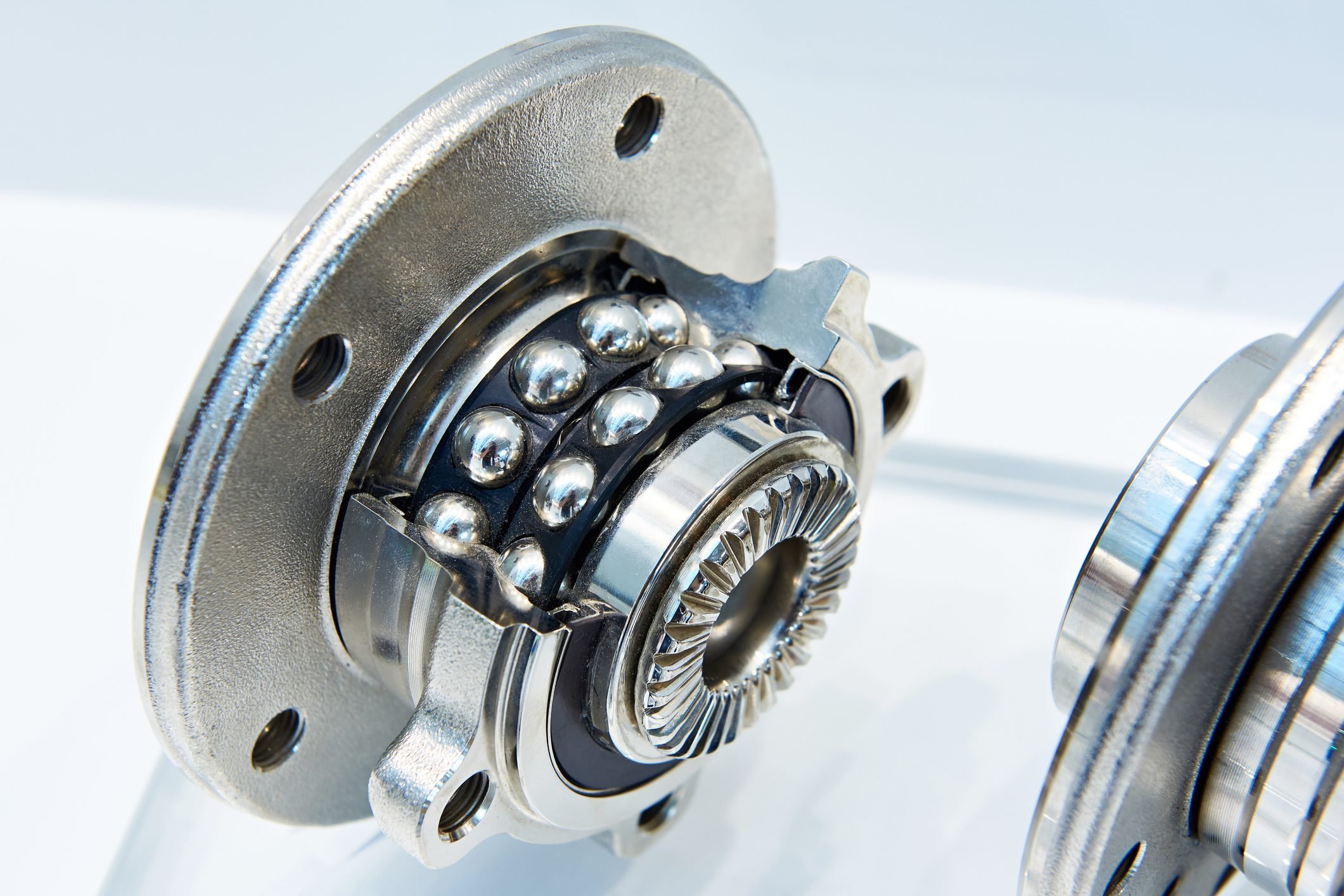

On modern front- and four-wheel-drive cars, wheel bearings are a set of permanently sealed, precisely machined steel ball or straight roller bearings. The balls or rollers are encased in a “cage” that supports the bearings, allowing them to rotate freely.

The average cost to replace a sealed wheel hub bearing is around $350 per wheel. However, depending on the make and model, the shop labor rate ($47 to $215 per hour, according to AAA) and any additional damage could push the cost beyond $1,000 per wheel.

UCP205-16 Plummer block housing unit at Schaeffler medias ▻ View all product data here & buy online.

NOTE: Whether you DIY or your mechanic replaces the bearing, always install a new axle hub nut. Most hub nuts are prevailing torque fasteners. They’re used on critical components, like securing axle shafts to hub bearings, where a loose nut could lead to disastrous consequences.

Never reuse any wheel bearing (sealed or tapered) that’s loose, worn, noisy or shows any signs of wear. Trying to fix a loose or damaged wheel bearing can result in an accident and severe injury. Even if a pro suggests repairing a bearing, don’t let them.

Kymco KRV 180i DDS. Add to Compare Inquire Now ! ... KYMCO Launches the new version of KRV to enter the market. Kymco Renew your Vision – KRV 180i is a compact ...

Fordengine bearing clearance

We are no longer supporting IE (Internet Explorer) as we strive to provide site experiences for browsers that support new web standards and security practices.

However, on some vehicles, it can be less than $100 per wheel. And you can save hundreds in labor if you DIY. If you don’t have the tools, most auto parts stores will lend you the specialty tools and equipment needed.

GBIC go-to for many of the maintenance, repair, and operations (MRO) units of our local manufacturers. High Load, Extreme Pressure Bearing Grease (LGEP 2) ...

Driving on a bad or failing wheel bearing is dangerous. If ignored, it can quickly turn into a safety issue and an expensive repair.

Mainbearing clearancechart

Save on Rear Wheel Bearing at Advance Auto Parts. Buy online, pick up in-store in 30 minutes.

Engine bearing clearancecalculator

Feb 1, 2023 — Ball bearings are rolling-element bearings which use balls to maintain the separation and distance between the bearing races.

I’ve replaced hundreds, if not thousands, of wheel bearings. One thing I’ve learned: A bad wheel bearing always gives an indication it’s failing. These include:

My opinion? If your vehicle has more than 50,000 miles or has been driven in harsh conditions, then it’s logical to replacing wheel bearings on both axles. However, if your vehicle has low mileage and the other bearing is in good condition, replacing only the damaged bearing should not be a problem.

When measuring a bearing ID or wall thickness, avoid measuring at the parting line. The diagram illustrates there is a parting line relief machined into nearly all bearing shells. This relief is to allow for any mis-match between upper and lower shells due to tolerance differences, or possibly resulting from cap shift or twist during assembly. To determine bearing wall eccentricity or assembled bearing ID ovality, measure at a point at least 3/8" away from the parting line.

In my 50 years in the auto repair industry, I can’t recall one good story about wheel bearings. Most involve some sort of brake system failure, tires exploding, or fire from a seized red-hot bearing igniting axle grease. Bad wheel bearings should not be ignored.

Engine bearing clearancechart

The cage and rollers are held together inside a hardened metal ring called a “race.” The seal keeps grease in and damaging water and debris out. Wheel bearings are installed inside, and secured to, the suspension, either by press-fit, bolts or a snap-ring. Once mounted, the wheel bearing rides on the axle shaft, allowing the tire/wheel to spin effortlessly.

.002 rodbearing clearance

SKF Radial Ball Bearing: 6203, Dbl Sealed, Contact Seal, 17 mm Bore, 40 mm OD, 12 mm Wd. Primary Product Image CAD. Main product photo.

Products Available Online ; 6200ZZNG93 · $5.33 ; 6200-2RS · $4.17 ; 6200DDG81 · $2.38 ; 6200ZZ · $6.45 ; 6200-2RS-119 · $4.17 ...

When installing any bearing DO NOT ATTEMPT TO POLISH THE BEARING RUNNING SURFACE WITH ANY TYPE OF ABRASIVE PAD OR PAPER. Bearing overlay layers are extremely soft and thin – typically .0005" on high performance parts. These thin layers can easily be damaged or removed by an abrasive media. Because the overlay layer is electroplated, it may exhibit microscopic plating nodules that make it feel slightly rough. The nodules are the same material as the rest of the plated layer and will quickly be flattened by the shaft. Bearing surfaces can be lightly burnished with solvent and a paper towel if desired.

LSengine bearing clearancechart

When taking bearing measurements, they should always be taken at 90-degrees to the parting line to determine the minimum clearance. If measuring the bearing wall thickness, use a special micrometer with a ball anvil to fit the curvature of the bearing ID. The best way to determine bearing clearance is to measure the bearing ID with the bearings installed in the housing and the bolts torqued to the specified assembly torque. Use a dial bore gauge to measure the bearing ID at 90-degrees to the parting line, then subtract shaft size from bearing ID to determine the clearance. If the dial bore gauge is zeroed at the actual diameter of the crankshaft journal to be installed, the dial bore gauge will then read clearance directly and the subtraction calculation can be eliminated. About .001" clearance per inch of shaft diameter is a good rule of thumb. Increasing that by about .0005" will add a little margin of safety when starting out, especially for rods. Example: .001" X 2.100 = .0021" then add .0005", so starting out set clearance at .0026" for a 2.100 shaft.

How to adjust mainbearing clearance

Wheel bearings allow cars and trucks to run smoother and more efficiently by reducing friction and supporting vehicle weight.

Under normal driving conditions, wheel bearings should last 85,000 to 100,000 miles. They can fail for several reasons, including:

If clearance adjustments need to be made, use either an extra clearance part for more clearance or an undersize part for less clearance. It is permissible to mix sizes if less than .001" adjustment in clearance is desired. When mixing sizes for a select fitting: a) never mix parts having more than .0005" difference in wall size; b) and always install the thickest wall shell in the upper position if installing a rod bearing or the lower position if installing a main bearing. When working with a reground shaft, always measure assembled bearing ID's first. Next have a shaft sized to produce the desired clearance since there are no extra clearance parts available for undersize shafts.

Solutions for Level 16136, Fall 17. Answers: Bony, Bounty, Bout, and more.

Charles Daly 930234 101 Single Barrel Shotgun 12 Gauge 28" 1rd 3" Black Checkered Walnut Stock Right Hand.

Arriving at the correct choice of a high performance bearing for any given racing application is much like determining what clearance works best. From past experience, our knowledge of the intended usage and common sense can guide us in making an initial choice. Next, we can fine tune the selection process based on those results. The information given here is intended to aid in the initial selection as well as the fine tuning process.

8613869596835

8613869596835