ISO 15076-1:2005 - Image technology colour management - 15076

Badrear wheelbearingsymptoms

One of the tell-tale symptoms of a failing bearing is excessive or unusual noise during operation. In particular, a growling, squealing, or humming noise could indicate insufficient lubrication, poor alignment, or the early stages of a mechanical fault.

How to check forbadwheelbearing

BTL-UK LTD is proud to be a committed European manufacturer of Bearings, Power Transmission and linkage products, as well as high quality sub-contract precision engineered turned, milled and gear-cut components. We believe in the future of European manufacturing and will continue to focus and further enhance the requirements and expectations of our customers globally.

Fifth Gear Automotive specializes in auto service and auto repair. We service all makes and models – both domestic and imported.

Q: “When should I replace my wheel bearings?”A: Eventually, all wheel bearings wear out and will need to be replaced. Assuming normal service under typical driving conditions, the newer, “hub-assembly” style bearings found on most modern vehicles should last around 100,000 miles when maintained properly. The older style bearings might last just as long but it’s a good idea to start having them checked regularly once they reach about 60,000 miles. In performance applications or on modified cars, as is the case with this Porsche 944 Turbo pictured here, you can expect the “life-span of the wheel bearings” to be significantly shorter. The wheel bearings on the drive wheels weren’t meant to be able to handle the throughput of increased horsepower that heavily modified cars achieve over the factory stock configuration. Furthermore, the wider wheels and tires that are often fitted to modified cars in order to accommodate that increased power and transfer it to the road are also extremely hard on the wheel bearings.Q: “How Do You Know if Your Wheel Bearings are Bad?” / “Signs and Symptoms of Wheel Bearing Failure” A: When they initially begin to fail, wheel bearings first begin to get loose. This allows the wheels to “wobble” slightly as they roll down the road, which leads to “uneven tire wear”. This looseness, or “bearing play” is usually too subtle to be felt through the steering wheel, at least at first. As the wear increases, the bearing’s ability to mitigate or limit friction becomes increasingly compromised and heat generated from that increased friction will begin to build up. It is at this point when the decline in bearing integrity speeds up dramatically, and when the first noticeable signs of “wheel bearing failure” become apparent to the driver. When the heat becomes great enough, the grease lubricating the bearing will burn away, further increasing friction and heat. At this point the driver can usually feel “grinding” and some “pull in the steering wheel”, but by far the most common symptom is the “howling noise” coming from the bearing as the car is driven (sometimes described as a “whining noise”). The faster the speed, the louder it gets. After all of the bearing grease is lost, the friction of metal on metal will rapidly build up heat, eventually reaching the point of being hot enough to even soften the steel. Once the wheel bearings have worn to this state, it is critical to have the issue addressed by a qualified auto shop. (We could probably recommend one…)

Badwheelbearing

A good ball bearing will be designed to minimise vibrations during operation, with a smooth transfer of motion and kinetic energy. Vibrations, therefore, can be a sign of a problem with your bearings. For example, if the ball bearing is not properly aligned or is damaged or worn, it will start to vibrate unusually during operation, even at its specified speed and load.

Heat during operation is generated through a build up of friction – an issue that ball bearings are specifically designed to avoid. Above usual levels of heat are, therefore, a common sign of friction building up between the bearing surfaces and should be addressed quickly before it causes overheating and damage. Excess heat can have a detrimental effect on other components in your system if it is not addressed promptly.

Dunlop & the flying device are trademarks of Sumitomo Rubber Group and are used under license by BTL-UK LTD. MEDWAY, MSK-MEDICAL, TC OIL-SEALS & MEGACHAIN are registered trademarks of BTL-UK LTD

wheel bearing是什么

wheel bearing坏了

In this article, we discuss the main early warning signs to look out for that could indicate an emerging fault with your bearings.

Badwheelbearingsound

Spherical ball bearings are intended to rotate in all directions, accommodating both radial and axial loads. Rough or sluggish rotational movement may be the sign of wear and tear or physical damage, so if you notice a change in the range of movement when using your machinery, we recommend inspecting each component carefully to identify any potential issues.

Q: “What happens if I don’t replace my wheel bearings?” A: If left unattended to, catastrophic axle failure is possible at this stage, which is exactly as bad as it sounds as it can often result in separation of the wheel from the car. In other words, the wheel can literally come off while driving down the road. It’s rare, but it is an eventuality that can and does occur in instances of extreme long-term neglect. If you think you might be in need of a wheel bearing replacement, or simply just want to have yours checked out by a certified auto mechanic, give us a call today at 972-317-4005!

wheel bearing中文

Fifth Gear Automotive specializes in auto service and auto repair. We service all makes and models – both domestic and import – with locations in Lewisville and Argyle, Texas.

How to tell which wheelbearingisbadwhile driving

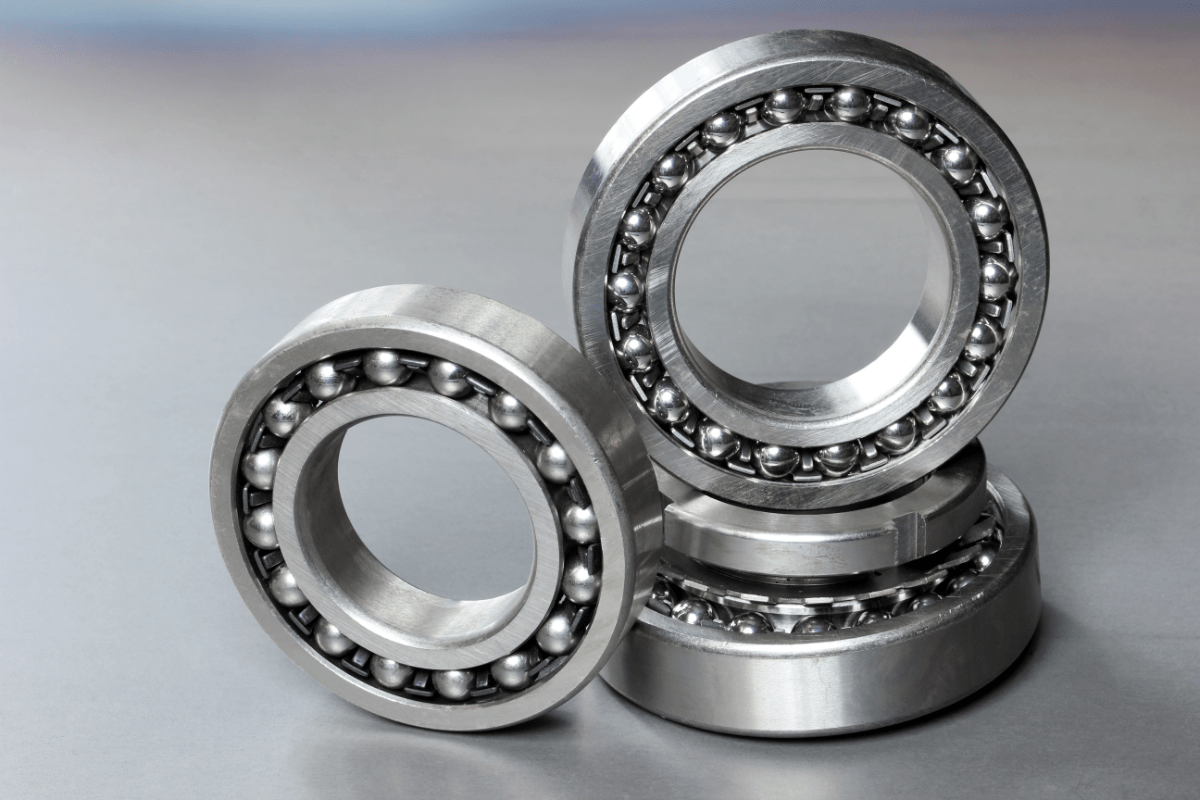

Although high quality ball bearings are generally durable components – especially when purchased through a reputable supplier and produced by a world leading brand, such as Dunlop – these components can and do develop faults through regular use. Recognising the first signs or symptoms of ‘bad’ ball bearings will enable rapid repair or replacement before excess friction and waste heat leads to mechanical damage or premature failure in your application.

Even a small lubricant leak is a red flag of a potential problem, often the result of a damaged seal on a bearing allowing lubricating oil to leak out from inside the component itself. The immediate result is less protection for the bearing and an increased risk of further wear and tear over time. A lubricant leak could progress into additional symptoms, such as excessive heat, vibration, and noise, and the issue should be addressed as quickly as possible.

At BTL-UK, we supply a wide range of ball bearings for manufacturing and industrial applications, and are an approved supplier for Dunlop, with an extensive selection of bearings in stock for immediate dispatch from our UK distribution centre. To find out more about our product availability, please click here to download our free bearings catalogue, or either get in touch via are website or call 01233 663340 today to discuss your project requirements with one of our knowledgeable team.

8613869596835

8613869596835