ISO 15750-3:2022 - Packaging — Steel drums — Part 3 - 15750

6203lu bearingspecs

Grease life can be estimated by the following equation when a single-row deep groove ball bearing is filled with grease and sealed with shields or seals.

6203LU Bearingautozone

The values obtained by the above equation show quantities of oil required to carry away all the generated heat, with heat release not taken into consideration. In reality, the oil supplied is generally half to two-thirds of the calculated value. Heat release varies widely according to the application and operating conditions. To determine the optimum oil supply, it is advised to start operating with two-thirds of the calculated value, and then reduce the oil gradually while measuring the operating temperature of bearing, as well as the supplied and discharged oil.

In the example, the inside of the housing is divided by grease sectors. Grease fills one sector, then flows into the bearing. On the other hand, grease flowing back from the inside is forced out of the bearing by the centrifugal force of the grease valve. When the grease valve is not used, it is necessary to enlarge the housing space on the discharge side to store old grease. The housing is uncovered and the stored old grease is removed at regular intervals.

Bearing lubrication is classified broadly into two categories: grease lubrication and oil lubrication. Table 12-1 makes a general comparison between the two.

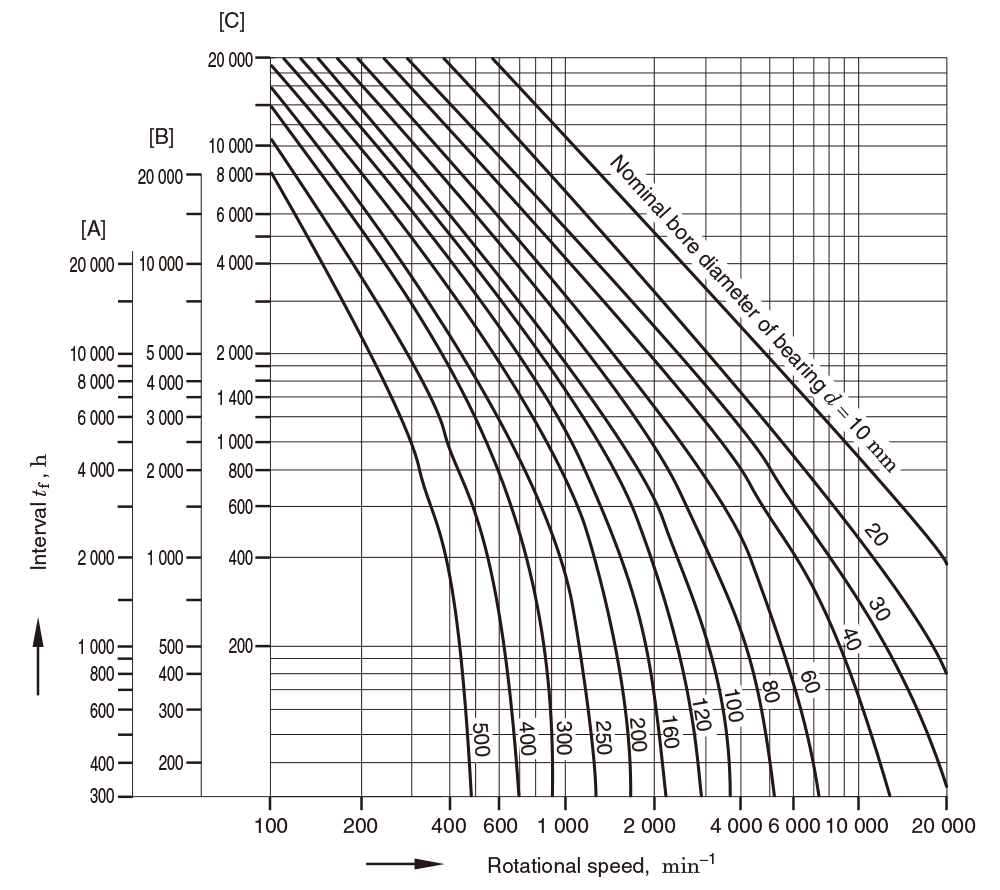

In normal operation, grease life should be regarded roughly as shown in Fig. 12-2, and replenishment/replacement should be carried out accordingly.

6203LUpulley

Oil lubrication is usable even at high speed rotation and somewhat high temperature, and is effective in reducing bearing vibration and noise. Thus oil lubrication is used in many cases where grease lubrication does not work. Table 12-2 shows major types and methods of oil lubrication.

(Oil mist lubrication has a number of advantages for high speed rotation bearings. Its performance, however, is largely affected by surrounding structures and bearing operating conditions. If contemplating the use of this method, please contact with JTEKT for advice based on JTEKT long experience with oil mist lubrication.)

6203LU Bearingdimensions

Lubrication is one of the most important factors determining bearing performance. The suitability of the lubricant and lubrication method have a dominant influence on bearing life.

Grease lubrication is widely applied since there is no need for replenishment over a long period once grease is filled, and a relatively simple structure can suffice for the lubricant sealing device. There are two methods of grease lubrication. One is the closed lubrication method, in which grease is filled in advance into shielded/sealed bearing; the other is the feeding method, in which the bearing and housing are filled with grease in proper quantities at first, and refilled at a regular interval via replenishment or replacement. Devices with numerous grease inlets sometimes employ the centralized lubricating method, in which the inlets are connected via piping and supplied with grease collectively.

6203lu bearingcross reference

I am replacing idler pully bearing in my suv, the model# for the old bearing is 6203lax30 will the bearing you list still work?

The method of replenishing/replacing grease depends largely on the lubrication method. Whichever method may be utilized, care should be taken to use clean grease and to keep dirt or other foreign matter out of the housing. In addition, it is desirable to refill with grease of the same brand as that filled at the start. When grease is refilled, new grease must be injected inside bearing. Fig. 12-1 gives one example of a feeding method.

In general, grease should fill approximately one-third to one-half the inside space, though this varies according to structure and inside space of housing. It must be borne in mind that excessive grease will generate heat when churned, and will consequently alter, deteriorate, or soften. When the bearing is operated at low speed, however, the inside space is sometimes filled with grease to two-thirds to full, in order to

When the flow rate of mist in piping exceeds 5 m/s, oil mist suddenly condenses into an oil liquid. Consequently, the piping diameter and dimensions of the lubrication hole/groove in the housing should be designed to keep the flow rate of mist, obtained by the following equation, from exceeding 5 m/s.

8613869596835

8613869596835