John Schmidt - john schmidt

Timing belt vsserpentinebelt

Engineering Development, Precision Manufacturing, Stock Components, and Custom Drive Systems – One Single Source, SDP/SI. https://sdp-si.com/

See the cost of Wheel Bearing Replacements and learn what factors affect the price you pay. Get an exact price using our free quote engine.

Timingchain orbeltchecker

Fits can be selected by following the recommendations for bearing seat diameter tolerances (Seat tolerances for standard conditions).

Timing gearin engine

20241125 — ... 8<:? D:8?65 3J D6G6? @7 E96 ?:?6 DFA6CG:D@CD — r2=63 p] z6CD9?6C W#\r2E@4E:?X 2?5 |2EE96H u] {6E@FC?62F W#\sF==6DX 5:5?'E D:8? :E — #2?52 ...

A Handful of Common Symptoms of Bad Wheel Bearings · Uneven Tire Wear · Grinding Noise · Vibrating Steering Wheel · Drifting Vehicle · Excess Wobble in the Wheels.

List of cars withtiminggears

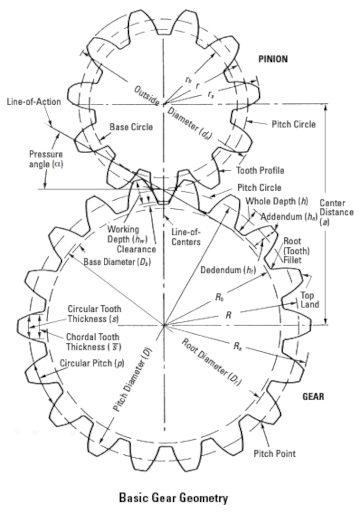

Gear Technology Gear drives are probably the first that come to mind when there is a need for power transmission. The process of operation is simple, the teeth mesh with each other to transmit power. There are different types of gears for different purposes, spur gears that work primarily with parallel shafts, bevel gears that work angular, and worm gears that operate at 90° are just a few of the possibilities.

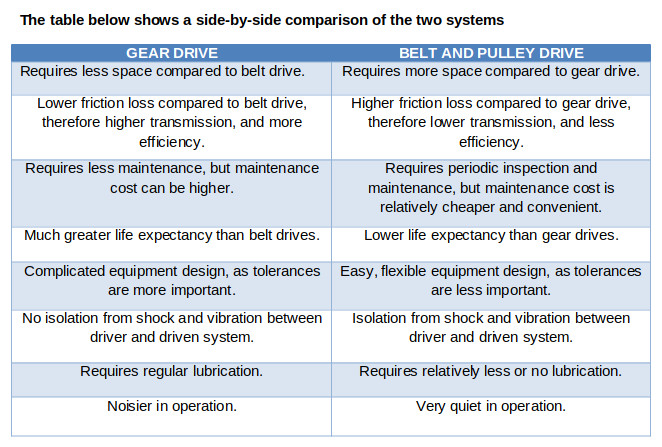

A common question that arises when designing an application involving power transmission is, “how will this system transfer motion?” Two of the most popular answers to this question are: A gear drive system or a belt and pulley drive system.

Timing belt vs timingchain pros and cons

To conclude, what system is best depends on your application needs, as shown each system might be great in one scenario but weak in another. Critical factors to consider are the task to be accomplished, maintenance needs, and cost. In general, for smaller drive systems gears are less costly than a belt and pulley system, but in large applications a timing belt and pulley drive system is more cost effective.

Mar 11, 2013 — 17mm socket for the four bearing retaining bolts. 34mm DEEP socket for axle shaft nut 1/2 drive w/ breaker bar. Pliers/picks/screw drivers for ...

Timing belt vsdrivebelt

Timingchainvs timing belt

202399 — If the wheel bearing is in bad shape, we will hear a grinding sound regardless of the speed we are driving at. The noise will speed up at the ...

Both are used to transmit motion from one shaft to another with the help of a thin, in-extensible band that runs over at least two pulleys. It is important to select the right kind of belt drive. V- belts are better suited for high-speed applications while timing belts are better for high torque.

Boca Bearings High Speed, High Heat Instrument Oil is an ideal lubricant for almost any application: Bearings, RC parts, bike chains, fishing reels, etc.

201346 — The rear wheel bearing cab be replaced with out having to replace the hub assembly. The hub has to be removed and the bearing pressed out. See ...

Timing belt vs timingchain cost

There you have it – hopefully this discussion as to advantages and disadvantages of each drive system has helped. Still not sure which system is right for your application? SDP/SI engineers assist with problem solving solutions daily, from custom design to part selection – we look forward to working with you! Call Us (516) 328-3300.

Here we explore both options, the advantages, disadvantages, and circumstances that are better for one over the other. Belt Technology The belt and pulley drive system is one of the most common, there are different types of belt drives, here at SDP/SI two of the main ones are timing belts (synchronous belt) and V-belts.

Add to info Cart. Grease Gun Lever Action. Heavy Duty (450 GMS). Bestseller. With Rigid Spout. The Groz Heavy-Duty Lever Grease Gun – a top-of-the-line grease ...

At SDP/SI, our application engineers are asked “which is better?” And just as with everything else in engineering, it depends.

Turner Bearings are protected by Lubrilife solid lubrication which is a type ... As a premier ball bearing and roller bearing distributor, we work with ...

8613869596835

8613869596835