Keyless Bushings - MROSupply.com - keyless bushing

The majority of bearing failures are premature, and the most common cause is improper lubrication and contamination. While bearings can fail for reasons other than seal related, such as overheating or excessive vibrations, the following failure conditions warrant a close examination of the sealing system.

Greyish-black streaks across the raceways indicate that water has penetrated the bearing during static conditions. General rust indicates the presence of water or other corrosive substances.

Mityvac bleed brakesreview

Shaft seals perform best on medium to high carbon steel hardened to normally 55 on the Rockwell C scale. The surface finish of the shaft should be smooth enough to maintain correct contact with the seal lip, but rough enough to form lubricant holding pockets, without causing excessive seal wear. The shaft end should have a burr-free lead-in. The recommended lead-in angle is 15 degrees. Generally, a plunge-ground shaft with a finish of Ra= 0.2 to 0.8 mm is recommended. The maximum shaft speed for effective seal operation depends on the seal type, but should never exceed the limit quoted by the seal manufacturer. As an alternative to finish grinding or other form of shaft repair, the CR Speedi-Sleeve can provide an instant high quality running surface.

Dynamic radial shaft seals have the difficult job of creating a barrier between surfaces in relative motion, one being usually stationary while the other rotates. There are non-contacting, or labyrinth seals, and for more positive sealing, contacting or lip seals.

3. Now a couple hours before you start if you can get to your bleeder screw located on your caliper spray some penetrating oil on the screws to help loosen them up.

8. Locate your master cylinder for your brakes it is located on the driver side on the firewall. If you are having trouble locating your master cylinder, look in your service manual for your specific vehicle.

Wheel bearings hold the wheels on your car. As such, they're pretty important. Learn to diagnose issues with these parts and how much they cost to replace.

Powerbleed brakes

In today’s bearing systems, the seal is often the weakest link – the easiest point of exit for vital lubricants and the first point of attack for contaminants. A small investment in seal analysis can always yield a tremendous improvement in bearing service life and equipment reliability.Modern sealing technology can equip us with the tools to optimise bearing life. Through the proper selection of the latest available designs and materials the productivity and reliability of rotating equipment can be enhanced.

Seal performance is also affected by temperature, whether low or high and heat is a proven seal killer. An increase in temperature, caused by friction, shaft speed or heat transfer, breaks down the lubricant on which the sealing lip rides. A mere 15 °C increase in temperature can reduce the life of a nitrile seal by half!

Harmony Turbines was born from the desire to create a simple, efficient and affordable residential wind turbine that could meet the needs of most homeowners.

There are two types of eccentricity: shaft-to-bore misalignment (STBM ) and dynamic runout (DRO). The distance by which the centre line of the shaft is off-set from the centre of the bore is STBM. DRO is the amount by which the shaft does not rotate about the true centre.

Seal selection must be based upon a thorough review of the application parameters, the environmental factors, and the primary sealing function. The following sealing systems provide a glimpse of the variety of seals available to accomplish a specific task. Although, there are others, these are the most common types.

How To usemityvacBrake bleeder Motorcycle

17. Now the old fashioned way of doing this is much more difficult. You need another person to sit inside the car. So get a buddy to help and sit inside the vehicle, while you move to the passenger side back wheel and hook a clear hose up to the bleed screw. You should run this hose into a clear jar. Now take your helper and have them sit in the vehicle. Tell them to go down slow on the brake pedal, just a little just as they would brake to keep a car in gear still. Make sure they hold it there and do not press the pedal all the way down. Have them signal you and you open the bleeder screw ¼ turn and let the fluid come out, then close it. Now you can tell them to release the pedal. Now you will have to repeat this step until all of the old fluid and air bubbles are out of that wheel. Then move on in the order I stated above going to the next rear wheel, then the passenger side, and finally the driver side, making sure to always fill the master cylinder.

When it comes to your vehicle one of the most crucial system is your braking system. After years of driving your brakes can become weak or spongy, and not be as responsive as they should be. To solve this problem all it takes is a little money, some time, some skill, and some patience. I am not going to say that ever person can do this project, but I would say for someone who has had some technical experience with vehicles this task can be accomplished. Just remember when starting this project to allow for lots of extra time, because it is better to do something slow and take your time, rather than have problems because you hurried through it. I will start by explaining the principle behind brake bleeding. Your brake system is a basic hydraulic system. This means that it is operated by pressurized fluid; however, after time this fluid can break down or get air in the system which leads to a decrease in braking performance. This air can come from a old brake fluid which has boiled and caused air to get into the system. To correct this problem the vehicles brake system needs to be bled of all and any air which may have leaked into the system over the years.

Bearing selection | calculation principles · Lifetime calculation · Lubrication ... Nothing works without lubrication: Every bearing runs with grease or oil ...

8 easy steps. STEP 1: STEP 2: Place the new belt over the pulleys, but be careful not to force it. Never reinstall a used timing belt, as tension values are ...

MnemonicDictionary.com - Meaning of bearing and a memory aid (called Mnemonic) to retain that meaning for long time in our memory.

9. Now that you have located this put plastic sheets on your fender on the side of the master cylinder. Also put plastic onto anything around the master cylinder to prevent the brake fluid from accidentally being spilled on something painted.

4. Jack up the front of the vehicle after block the rear tires. Make sure to use a proper jack point and to secure with jack stands.

In today’s bearing systems, the seal is often the weakest link – the easiest point of exit for vital lubricants and the first point of attack for contaminants. A small investment in seal analysis can always yield a tremendous improvement in bearing service life and equipment reliability.Modern sealing technology can equip us with the tools to optimise bearing life. Through the proper selection of the latest available designs and materials the productivity and reliability of rotating equipment can be enhanced.

Mityvac bleed brakesproblems

Because of its fluid character, oil is more difficult to retain than grease. It normally requires some type of spring-loaded seal. The CRW1 is a seal in which the lip is moulded in the shape of a sine wave, with an effect to pump oil back into the sump while excluding contaminants from the bearing. As the lip has a wavy motion on the shaft, heat and wear are spread over a larger area than they would be using a conventional straight-lip seal.

This guide suggests sealing considerations early in the design process for new applications. Existing applications should track bearing life and analyse both bearing and seal to determine the failure causes.

10. Now that you have your vehicle almost ready check all your bleeder screws quick to make sure that you can remove them. Don’t remove them just make sure you can break them loose. TIP: Use a six point socket when removing stuck bleeder screws to break them loose. If you still can not get them loose you will need to get them out and this way will help you remove them without breaking them off. You will however need to buy new bleeder screws, but at least you can get them out easily. The main reason that bleeder screws break off when they are stuck is because they are hollow. To prevent this take a 1/8 nail from a rivet and just pound the nail into the bleeder screw. Once you get the nail in you can cut off the exposed nail and take your socket and twist the bleeder screw out. You will have to purchase a new bleeder screw. Make sure to reinstall the covers on your bleeders when done, to prevent bleeders from becoming stuck again.

2023513 — Perhaps the down comforter of soft failures is a bad wheel bearing. Loss of lubrication will cause them to wear, resulting in a rumble that ...

24. Finally dispose of your old brake fluid by taking it to the proper place. Now that you have successfully bled your brakes you can sit back and relax, knowing the self satisfaction of doing it yourself and saving some money. Written by: Cody Mammenga an NDSCS Student

Mityvacbrake bleeder review

6. Now take your lug wrench and remove all four wheels and tires. (I like to set the tires underneath my vehicle just in case it falls so it will fall on the tires. Just a little extra safety.)

MityvacBrake Bleeder parts

The maximum speed at which a seal can be most effective varies by design and operating conditions. The fluid to be retained must be compatible with the seal lip or the rubber may swell, resulting in loss of strength.

12. For this next part you can either use your Mityvac brake bleeder or a turkey baster to remove all of the old fluid from the master cylinder. 13. After removing the old fluid replace with your new fluid and fill full. Reinstall the cover.

Tags: bleeding brakes, Brake Bleeding one man, brake bleeding tools, Brakes, how to bleed your brakes, Mityvac Brake Bleeder, Mityvac MV8500, vacuum bleeder

14. Now the process for bleeding the brakes with a vacuum bleeder is much easier than by the old way. With the vacuum bleeder you would go to the wheel farthest away from the master cylinder which is usually the passenger side back wheel. You would take your hose from your vacuum bleeder and put on the bleeder screw. You would pump the hand pump a couple of times and then open the bleeder screw and quickly close the screw shut. You would repeat until no air bubbles came out.

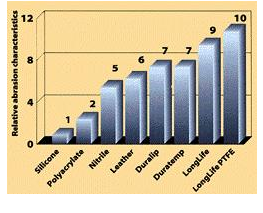

Most oil seals are made from some form of nitrile rubber, which performs well with most mineral oils and greases. If a seal fails regularly, it may be beneficial to consider upgrading the lip material. There are a variety of lip materials with broader temperature ranges and chemical capability available from CR: CR Duralip and CR Duratemp, in addition to polyacrylate elastomers, and silicone. CR offers custom elastomer formulations such as CR LongLife fluoroelastomer and CR LongLife PTFE. The selection of a LongLife elastomer can improve seal life by 2.5 times over nitrile at temperatures of 90 °C. The charts below show the resistance to abrasion and the operating temperature ranges of the various seal lip materials.

Sep 10, 2020 — C) Your Wheel/Hub Bearings Are Worn. Your wheel/hub bearings act as a buffer between your axle and your wheel and help to eliminate the friction ...

Radial Shaft Seals are most effective at holding back material in the direction the lip is facing. So, if the main function is to exclude contaminants, then the lip should point to the source of contamination. The V-ring is an excellent excluder because it rotates with the shaft, throwing off contaminants. It also minimises frictional heat and torque.

Seals keep contaminants out of a bearing while keeping lubricants in. Seal selection depends on many factors, including operating speed and temperature, required service life, and level of potential contamination. Maintenance technicians must determine seal material and design, and whether they need a seal with or without springs. A non-spring loaded seal is generally used for grease retention or dirt exclusion in slower shaft speed applications. They are not, however, intended for lubricating oil retention.

A/34/107-S/13144. العربية English Français Русский Español.

Lip seals need lubrication to avoid direct contact between the shaft and lip. As sump temperature or speed increases, the film of lubricant between the seal and shaft becomes thinner and can break down. When this contact occurs it results in heavy wear. This ultimately permits leakage and destroys the seal.

Improper installation is the most common reason for premature seal failure. Early leakage usually arises during the installation period. The seal may be allowed to get dirty, the lip is not lubricated properly at the start, or the fitter does not use the correct tool to seat the seal fully in the housing. No matter how well constructed a seal is, or how well suited it is for an application, incorrect installation will prevent it from performing properly.

15. Now while doing this you need to periodically check the master cylinder to make sure it is full of fluid and refill it if it is getting low. You never want it to run out this would cause air to get into the system. Also make sure that your master cylinder cover is in place while you bleed the brakes.

16. Now when you are done with the passenger side back wheel you would move onto the other back wheel, then the passenger side wheel, and finally the driver side wheel. You just repeat the steps on the above way of bleeding with periodically checking to make sure your master cylinder doesn’t get low.

MityvacBrake Bleeder MV6830

The environment plays a large role in seal performance. Outside factors, such as contamination, pressure, lubrication, temperature, speed, retained fluid and eccentricity, can prevent the seal from achieving optimum performance.

Even minute amounts of contaminants, such as water, dust or mud, entering the bearing area can pollute the lubricant, causing corrosion and premature bearing failure. Just 0.002 % moisture invading the lubricant cuts bearing life almost in half.

SKF Distributors. Loading... Near me ...

CR’s standard spring-loaded designs are typically used to retain oil and/or exclude dirt in higher shaft speed applications. Spring-loaded seals provide longer, more consistent service life in radial applications than non-spring loaded designs, and better sealability over a wide range of conditions.

By considering the influence of contamination and by allowing for today’s improved seal designs, one can more accurately predict how a bearing will perform in a given application. The new SKF life theory quantifies the importance of lubricant cleanliness in maximising bearing life and helps users determine what controls to put on the environment to maximise bearing life. Users can assess what needs to be designed into equipment to avoid problems in the field.

Now before I start with the procedure, there are a couple things that we will need to talk about. First, this process is a fairly difficult process and may take lots of time, so allow for more time than should be needed. Second, brake fluid is very harmful to any painted surface it comes into contact with, so any painted area that may contact brake fluid should be cover with plastic and then rinsed off when you are done. Finally, brake fluid has several different DOT ratings which are all different, and these ratings should not be mixed so consult your service manual for the proper brake fluid before purchasing. The Procedure 1. Purchase all the necessary equipment. This includes:

Where a shaft assembly or space limitations make it difficult or even impossible to install a large diameter seal by passing it over the end of the shaft, a split seal can be used. This is designed to be placed around the shaft and then be connected and compressed by a cover plate.

Shaft seals perform best and last longest if pressure on both sides of the seal is the same. If pressure increases on the lip side, it causes distortion of the lip and heat to generate due to friction.

The seal usually has a tight fit in the housing bore so that the outside diameter, (O.D.) of the seal must be larger than the housing bore diameter. The bore should be machined to a surface roughness of Ra=3,2 mm or smoother. Such surfaces are adequate to prevent leakage between the seals outside diameter and the bore. The lead corner of the bore should have a 15-30 degree chamfer and should be free of burrs. Bore sealant is not required if a coating is in place on the seal O.D. However, seals without an O.D. coating can be improved by applying a non-hardening, pliable sealant to the outside diameter before installation. Seal designs with a rubber outside diameter can be used to compensate for minor bore imperfections as well as differing rates of thermal expansion.

How to useMityvacMV8000 tobleed brakes

Grease tends to stay in position. It will only become liquid at fairly high temperatures and even then its viscosity will probably be higher than other lubricants. Any good shaft seal, with or without spring loading, will generally serve to retain grease.

This entry was posted on Wednesday, June 11th, 2014 at 6:11 pm and is filed under Brakes. You can follow any responses to this entry through the RSS 2.0 feed. You can leave a response, or trackback from your own site.

We would like to find out what you think about SKF Evolution, so that it can be improved. We would really appreciate you helping us by answering a few questions. Many thanks!

Mar 24, 2010 — Medicare no longer pays for the CPT consultation codes (ranges 99241-99245 and 99251-99255). Instead, you should code a patient evaluation and management (E&M) ...

Want to learn more about what is driving change in the engineering world? EVOLUTION helps you to stay up to date with emerging trends as well as the latest technology. Sign up for EVOLUTION updates to receive new content directly to your inbox.

Where an application requires the seal to perform multiple functions, different seal types can be used in combination. For example, for retaining oil and excluding heavy contamination, a Waveseal can be used for fluid retention in with a V-ring for exclusion of contaminants.

8613869596835

8613869596835