Kohler K-22035-BL Simplice 4 GPM Deck Mounted Single - 22035

KaydonSKF

Combined radial/thrust bearings hold a special position among rolling bearings: They are capable of simultaneously handling very large radial and axial forces and are characterized by their particularly compact design. Findling Wälzlager offers combined bearings in a wide variety of designs and rolling member pairings.

It is not the load rating but the right overall technical specifications that are decisive when it comes to the service life and performance of roller bearings.

An essential property of greases and oils is the reliable mechanical separation of the rolling element from the raceway. Depending on the application, you need special types of grease to achieve this function. The following properties in particular affect the function:

Kaydon bearingcatalog

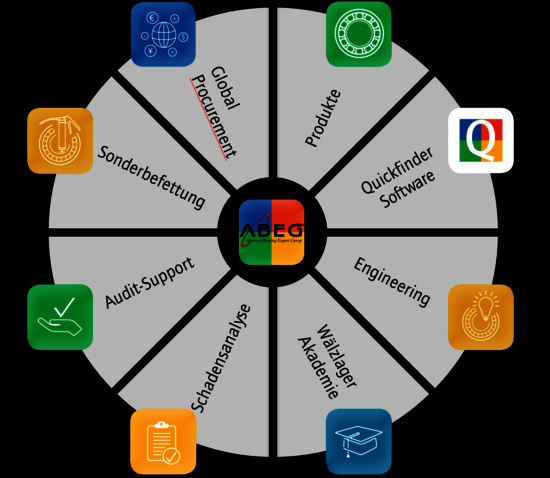

DevelopmentQuality laboratoryGlobal ProcurementE-ProcurementAudit SupportABEG QuickfinderSpecial greasingDamage analysisAcademyLogistics

How do I know if I’ve chosen the right bearing clearance class – C0, CN, CM, C2, C3...? An article from our konstruktiv! series. Tips series.

Closed-ended drawn cup needle roller bearings are closed on one side and serve as a closure for shaft ends. The rotating shaft is protected and sealed against interference.

Needle-roller bearings are characterized by their long, cylindrical rollers with a low cross section height. They are used wherever there are very high, shock-type loads. Karlsruhe-based Findling Wälzlager GmbH offers a comprehensive portfolio of roller bearing technology. In addition to designs from a wide variety of manufacturers and variants, the needle-roller bearing product group also includes needle roller and cage assemblies, drawn cup needle roller bearings with open and closed ends, and…

Kaydonthin section bearings catalog

Kaydon solutions meet the most exacting specifications of a broad range of applications for the aerospace and defense, commercial aerospace, heavy equipment, industrial machinery, medical systems, mining, oil and gas, radar, renewable energy, robotics, and semiconductor manufacturing markets.

Ball bearingsRoller bearingsNeedle-roller bearingsCam, yoke type track and running rollersHousing bearingsSpherical plain bearingsPlain bearingsLinear technologyLubricantsAccessories

The Kaydon thin section bearing product line includes Reali-Slim® and Ultra-Slim®; Real-Slim TT® turntable; cross roller; four-point contact; and tapered roller bearing designs. Kaydon bearings are available in the industry’s largest variety of materials, separator options, cross sections, internal fit up choices, lubricants, corrosion resistance options, contact angles, and precision levels.

Kaydon bearingCatalog PDF

Rolling bearing damage can have a wide variety of causes and is not necessarily caused by a faulty original product. However, most companies are unable to carry out a detailed damage analysis – good thing Findling Wälzlager’s experts can provide further assistance here: Damage analysis is part of the service portfolio. Findling Wälzlager acts as an independent partner that looks into the causes of the ball bearing defects and helps solve problems.

IntroductionYour foundationABEG® in purchasingABEG® in designABEG® in managementABEG® consultingQuality and safety ABEG® test

Kaydon’s slewing ring bearings offer Slewinfinite® solutions for the most demanding specifications in a wide range of applications. Choose from a variety of lines including: RK Series, HS Series, HT Series, MT Series, KH Series, XT Series, DT Series, XR Series, TR Series, WireX® wire-race bearings and Wind energy slewing ring bearings.

Kaydon bearingprice list

Kaydon bearings are manufactured in eight ISO 9001:2008 registered facilities around the world. Kaydon is committed to meeting the high levels of quality required by the industry and the markets they serve.

The world is spinning faster and faster. Complexity is increasing. Time is a precious commodity. Expert knowledge is in demand. We offer you modern roller bearing procurement without ifs and or buts: Experience comprehensive services in the field of rolling bearing technology from a single provider.

Kaydon bearingdistributors

We turned customized solutions into standard solutions with a high level of availability, even in small batch sizes. Particularly long-lasting high-performance roller bearings for high loads, high speeds, extreme temperatures and tough environmental conditions – that’s our ABEG® eXtreme series.

Our application engineer would be happy to analyze your application conditions and recommend suitable lubricants.Contact for applications consulting

Kaydonbearings location

Kaydon leads the industry in the design and manufacture of precision thin section ball bearings. Kaydon applies Thinfinite® engineering experience and expertise to solve the world’s most unique bearing challenges. The Kaydon Reali-Slim® inch-standard bearing is one of the most widely used thin section bearings in the world. Kaydon Thinfinite® bearing solutions save weight, create space, reduce friction, increase design flexibility, and provide excellent running accuracy.

Kaydonseals

That’s why, when procuring roller bearings, it literally pays off to work together with a partner who on the one hand has the necessary application experience and on the other hand not only offers standard products but also an optimized product range for specific industries. Findling Wälzlager GmbH supports its customers in a wide variety of industries with sound consulting and with economically and technologically optimum products.

Since 1941, Kaydon engineering experience and expertise has helped us solve some of the world’s most demanding bearing challenges. Kaydon’s exceptional engineering support provides our customers with problem-solving, application-specific custom and standard thin section ball bearings and slewing ring bearings.

Agricultural technologyPower transmission technologyAutomotiveConveying technologyFood technologyRobotics and automationPackaging technologyOther industries

Kaydon also leads the industry in the design and manufacture of precision slewing ring bearings. Slewing ring bearings include four-point contact, eight-point contact, cross roller, three-row roller, and wire-race configurations. Kaydon Slewinfinite® slewing ring bearing solutions are ideal for: Optimal economy in a given envelope dimension, Heavy-duty applications requiring significant load-carrying capacity, Designs where precise positioning is critical and The unique requirements of wind turbines.

Cage types may vary depending on the size and application type. We carry various cage designs made of steel sheet and plastic.

Open-ended drawn cup needle roller bearings consist of a needle roller and cage assembly that is held in a sleeve made of steel sheet. The sleeve serves as a parallel partner in the housing. These compact roller bearings offer the very highest load ratings in a very small space. Thanks to the sleeve, the housings can be manufactured from materials other than roller bearing steel, such as aluminum, cast iron or high-strength plastics. Because of the thin-walled design of the sleeve, it must be ensured that the housing is sufficiently solid. It is particularly important to note that the number of needles may vary while the dimension stays the same, which allows different load ratings to be achieved. The needle sorting used plays a particularly important role when it comes to precision.

The use of inner rings ground without twisting, for example in conjunction with radial shaft seals, comes with a series of advantages: Among other things, this makes it possible to prevent lubricants from leaking and increases the service life of the sealing lips. Findling now also offers these components in two performance classes. A high degree of automation during production also allows large-scale production to benefit from attractive conditions and a maximum level of efficiency as well…

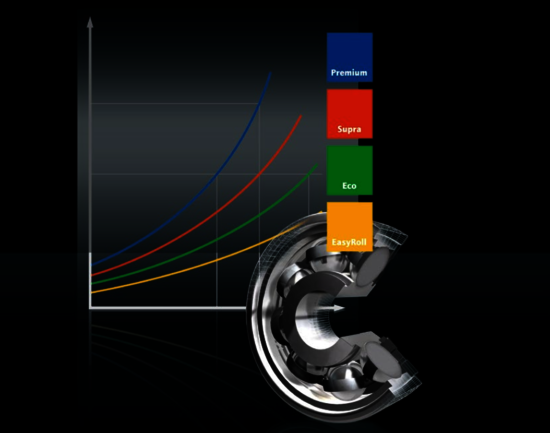

It has never been easier: With our four performance classes Premium, Supra, Eco and EasyRoll, you can also optimize your designs according to economic aspects.

8613869596835

8613869596835