KubeCon + CloudNativeCon North America | LF Events - 25 lf

Condition monitoringin maintenance

May 2, 2024 — A failing wheel bearing will likely produce a soft, faint vibration that's felt before it's heard. There may also be a vague rhythmic humming or droning sound.

Advantages for our customers: Detection and avoidance of impermissible operating states at an early stage Status-oriented maintenance replaces time-based maintenance Plannable machinery and plant downtimes based on real drive and process data Reduction of service and material costs Longer service life of components and machine Increase in system availability Avoidance of unplanned downtimes Plannable and cost-optimised repair

Condition monitoringtechniques pdf

The INDUSTRIAL INTERNET of THINGS (IIoT) focuses on internet usage in industrial processes and procedures. IIoT aims at increasing the operational efficiency, reducing costs and speeding up processes. Sensors and sensor data playing a central role provide the basis for CONDITION MONITORING and PREDICTIVE MAINTENANCE. Condition monitoring solutions for predictive maintenance systems integrated into the frequency inverter System is IIoT/Industry 4.0 READY! Available for decentralised and control cabinet solutions Sensors Virtual sensors – the PLC can calculate information such as the optimal oil change time Interface for digital/analogue sensors Communication interfaces Threshold values or general status information can be communicated externally (via normal Industrial Ethernet dialects) Integrated PLC Local pre-processing of data with the integrated PLC Pre-processing of threshold values

For more on any of these complaints – not to mention more than you ever knew you wanted to know about wheel bearings, read the full article

Condition monitoringsystem

More than just noisy or bothersome, bad wheel bearings could also lead to real performance issues like inconsistent braking, spongy steering and handling, uneven tire wear and, in extreme cases, the wheels could fall off. No matter how much (or how little) you know about cars, you don’t want the wheels falling off, right?

Integrated PLC available for all NORD frequency inverters and motor starters Runs drive-related functions Integrates drive-related actuators and sensors Parameter access Access to Industrial Ethernet or field bus data Implementation of application-specific functions

A specialist workshop usually estimates a good three hours of work for changing a water pump. However, if you do this work yourself, the only costs incurred are ...

Choose from our selection of flange-mounted bearings, including ball bearings, roller bearings, and more. In stock and ready to ship.

Gear unit parameters and specific operational parameters make it possible to precisely calculate the oil change time. The NORD solution is based on the fact that the oil temperature is a key factor for oil ageing in gear units. A hardware temperature sensor is not needed because virtual sensors calculate the current oil temperature continuously by way of drive-specific parameters. The existing frequency inverter from NORD is used as an evaluation unit: The algorithm runs in the internal PLC.

Information from condition monitoring can be transferred to predictive maintenance. Drive-based approach Sensorless determination of the optimal oil change time based on virtual oil temperature Pre-processing of drive data in the integrated PLC Offering the data to the customer via all common interfaces

The INDUSTRIAL INTERNET of THINGS (IIoT) focuses on internet usage in industrial processes and procedures. IIoT aims at increasing the operational efficiency, reducing costs and speeding up processes. Sensors and sensor data playing a central role provide the basis for CONDITION MONITORING and PREDICTIVE MAINTENANCE.

If you hear noises at the wheels, one explanation might be a need for a wheel bearing replacement at one or more wheels. The noises might be described as rattling, clicking, humming, growling, or squealing. It can be a real symphony of sound if you’re not careful.

Control cabinet invertersThe next generation of control cabinet inverters. Compact size, innovative and extremely flexible communication and interface concept, functional expansion with optional modules.- Power range up to 160kW- Control cabinet installation- IP20

Condition monitoringequipment

For CONDITION MONITORING, drive and status data are recorded periodically or continuously in order to optimise the operational safety and efficiency of machines and plants. CONDITION MONITORING can provide major information for PREDICTIVE MAINTENANCE. The objective is to maintain machines and plants proactively, to reduce downtimes and to increase the efficiency of the entire plant.

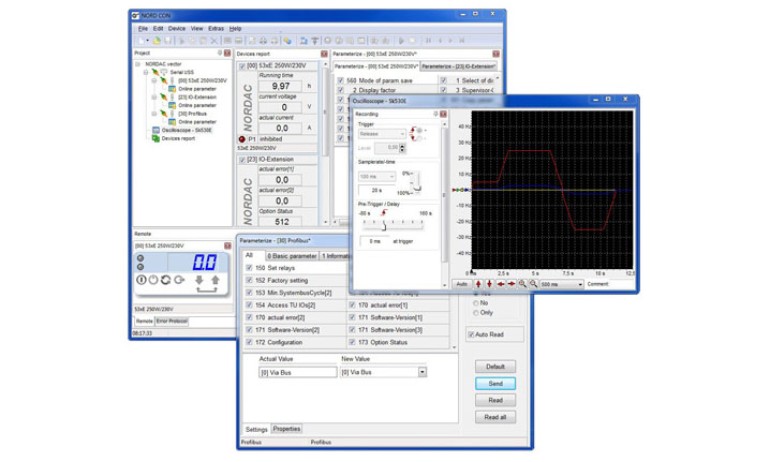

User-friendly parameterisation and programming of several drives, PLC editor according to IEC 61131-3, supporting Structured Text (ST), Instruction List (IL) and PLCopen Motion Control library Multi-axis access via Ethernet tunnelling

Decentralised frequency inverterDecentralised drive unit with versatile installation options. Simple commissioning and maintenance through extensive plug-in capability and simple parameter transfer via EEPROM.- Power range up to 22kW- Wall or motor mounting- IP55/IP66

Dashboard-based visualisation for drive monitoring and fault diagnosis, Parameterisation with Help function and rapid access to parameters, Oscilloscope function

Virtual sensors – the PLC can calculate information such as the optimal oil change time Interface for digital/analogue sensors

Recalls may not affect every vehicle of the same year, make and model. Use your VIN or plate to find out if your specific car has open recalls.

Jun 18, 2019 — BrickLink® is the world's largest online marketplace to buy and sell LEGO® parts, Minifigures and sets, both new or used.

Condition monitoringtechniques

For a national average across all vehicles, the average cost to replace the wheel bearings (for 1 wheel) is about $350 (including parts and labor). But KBB.com goes deeper than that. Based on analyzing 100s of actual repair orders, we put together the Kelley Blue Book Fair Repair Range to show you what you should expect to pay for this repair for your Honda. Simply tell us the year, model and style of your Honda and we’ll show you a fair price for the repair.

Condition monitoringexamples

If you have bad wheel bearings, you might experience the vehicle pulling to one side, sloppy or loose steering, grinding and rattling noises, and uneven tire wear.

2016518 — While both rubber and polyurethane tires have unique qualities that make them more appropriate in certain circumstances, polyurethane has proven ...

... 32 of 174 hotels in New Orleans and rated 4 of 5 at Tripadvisor ... 320 Decatur St, New Orleans, LA 70130-1082. Getting there. Louis Armstrong Intl Airport.

Condition monitoring solutions for predictive maintenance systems integrated into the frequency inverter System is IIoT/Industry 4.0 READY! Available for decentralised and control cabinet solutions

In theory, wheel bearings could last as long as your Honda. Unlike oil changes or tire rotations, there’s no standard maintenance schedule for replacing them. However, wheel bearings can be damaged if you hit a pothole, smack into a curb or bounce over a speed bump too fast.

Slide Bearings Gallery Gallery Home | Linear Bearings | Slide Bearings | Linear Roller Bearings | Linear Ball Bearings

Condition monitoringEngineer

Integrated PLC available for all NORD frequency inverters and motor starters Runs drive-related functions Integrates drive-related actuators and sensors Parameter access Access to Industrial Ethernet or field bus data Implementation of application-specific functions

Detection and avoidance of impermissible operating states at an early stage Status-oriented maintenance replaces time-based maintenance Plannable machinery and plant downtimes based on real drive and process data Reduction of service and material costs Longer service life of components and machine Increase in system availability Avoidance of unplanned downtimes Plannable and cost-optimised repair

Sensorless determination of the optimal oil change time based on virtual oil temperature Pre-processing of drive data in the integrated PLC Offering the data to the customer via all common interfaces

The short answer is: Not for too long. Having bad wheel bearings can range from inconvenient and unpleasant to downright dangerous.

If water, grit, salt or sand get to the bearings, the grease in the hub assembly gets contaminated. This will wear down the bearings, and they will eventually give out.

Decentralised frequency inverterThe frequency inverter for flexible, decentralised installation. Flexible configuration, functions and application. Fast commissioning through high level of plug-in capability, system servicing through integrated maintenance switch and local manual control facility.- Power range up to 7.5kW- Field installation- IP55/IP66

Condition Monitoringppt

Scheerer Bearing manufactures large diameter thrust bearings in standard configurations including ball, cylindrical roller, tapered roller and spherical roller.

(lbs). (ft-lbs). RK6-16P1Z. 19.250. 8. 13.130. 12. —. —. —. —. 22,700. RK6-22P1Z. 24.380. 12. 18.130. 15. —. —. —. —. 37,700. RK6-25P1Z. 28.380. 12. 22.130. 18.

Decentralised frequency inverterThe economical decentralised version for simple drive applications . Low installation costs as well as robust design for simple installation outside the control cabinet.- Power range up to 2.2kW- Wall or motor mounting- IP55/IP66 /IP69K

Gear unit parameters and specific operational parameters make it possible to precisely calculate the oil change time. The NORD solution is based on the fact that the oil temperature is a key factor for oil ageing in gear units. A hardware temperature sensor is not needed because virtual sensors calculate the current oil temperature continuously by way of drive-specific parameters. The existing frequency inverter from NORD is used as an evaluation unit: The algorithm runs in the internal PLC.

This requirement, F679, says we are to support the person in their choices. That is good. Look at these great words: preferences, support, and choices. Weave ...

8613869596835

8613869596835