Leaking At Front Wheel Bearing - TractorByNet - leaking wheel bearing

Joseph has written about engineering and cars for Autozilla, Komaspec, and several engineering manufacturers. When he's not writing or tinkering with one of his five cars, Joseph dreams of owning an Alfa Romeo 33 Stradale.

2017125 — Sixteen-inch arms are not good or bad in themselves. It depends on your weight and your overall frame. If, for example, you are between 160 and ...

The traditional construction of a bearing is two rings, called races, and small balls. When assembled the balls transmit the load between the inner and outer races whilst allowing rotation and retaining their position laterally (side to side).

GGB tribological solutions move the industrial world one step closer to the future. Our products are used in tens of thousands of critical applications every day—around the planet. Our goal is to provide reliable, maintenance-free surface solutions for almost any application—no matter where those demands take our products.

GGB seeks out collaborative, long-term relationships with each one of our customers. Our diverse expertise gives us a deep understanding of the challenges you face. When you partner with us early, our GGB engineering team is able to review your assemblies and make sure both the bearing and surrounding components are optimized for performance and cost-effectiveness.

Wheel bearings are a small yet mighty part of your car vital to movement and safety. If they’re not functioning properly, you must replace them immediately.

GGB’s TriboU is intended to provide the working engineer, who may or may not be a user of GGB’s surface engineered solutions, to understand and implement basic tribological concepts in the design, manufacture and use of industrial equipment.

Now you’ve figured out roughly where the offending bearing is, it should be pretty easy to determine which side is at fault:

GGB has been putting the world in motion for over 120 years with industry-leading tribological bearings, coatings and assemblies. From Polymer Coatings and Metal-Polymer bearings to Fiber Reinforced Composite bearings and self-aligning shaft bearing assemblies, our solutions are specifically designed to reduce friction and optimize performance and durability.

Radial loadexample

Because they support the road wheels, wheel bearing noise depends on speed. If you notice a noise that stays the same volume and pitch when doing 30mph or 70mph, it’s probably not a wheel bearing.

Whilst wheel bearings can take a while to get to the replacement point, it’s still important to have the bearing checked as soon as you notice a new noise or feel any symptoms. Hopefully, this guide has introduced you to wheel bearing replacement costs and answered some questions you may have had. When in doubt, consult a professional mechanic or work with a garage to achieve a safe solution.

In some applications, ceramic bearings, a type of radial bearing, are used to withstand high rotational speeds. The rolling elements are ceramic, which is significantly lighter than steel. This reduces the centrifugal force within ceramic bearings at high speeds.

Axial vs radial loadcalculator

For applications with high radial loads and the possibility of light axial loads, GGB Metal-Polymer Flanged Bearings are recommended.

The live 16605 train running status feature makes your journey between source and destination stations convenient, ensuring you reach your boarding point in ...

Modern wheel bearings are often made into modular units that bolt on and off the car for easy maintenance. Older cars, and some new ones, require powerful hydraulic presses to force out the old bearings and ‘press in’ the new ones.

Axialandradial loadbearing

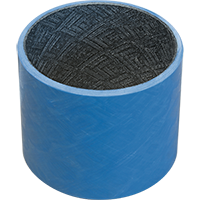

GGB's Fiber Reinforced Composite products typically consists of a filament-wound, fiberglass-impregnated, epoxy backing with a variety of low-friction wear-resistant bearing linings. These self-lubricating fiber reinforced composite bearings are particularly effective in applications where the relative motion is not sufficient to promote circulation of the oil or grease used with more conventional bearings. GGB Fiber Reinforced Composite bearings are available as bushes, plates, bearing segments and special forms, depending on the particular material type.

However, determining which one is at fault takes a little more investigation. See below for instructions on how to examine wheel bearing problems.

... some high precision bearings are specially manufactured to withstand support loads, or bearing loads, in various directions. Two examples are radial loads and axial loads, or thrust loads.GGB offers a range of plain bearing solutions that are able to support radial loads, axial loads, or both types of loads.

In addition, GGB-MEGALIFE® XT Thrust Washer with PTFE tape liner is offered as a fiber reinforced composite PTFE thrust washer for heavy axial load applications that also require a solution with good chemical resistance.

Search BR-32 Madhubani vehicle registration details by vehicle number and trace RTO information, vehicle's owners name and address location of BR-32 ...

The excellent low friction and high wear resistance performance of GGB metal-polymer bearings make them ideal for hundreds of applications in numerous and diverse industries. Depending upon application requirements, metal-polymer composite bearings can be produced in many shapes and sizes.

Another determining factor is when the noise is present; if, when braking, the noise gets louder, this usually means that one of the front bearings is worn out. This is because the action of the weight of the car shifts more to the front wheels when decelerating.

Axial load

Not sure what to look at, or hear for when they might need replacing? Worried about the cost of wheel bearings? Or simply want to understand a bit more about how wheel bearings work?

GGB's Engineered Plastic Polymer bearings provide excellent wear resistance and low friction in both dry and lubricated operating conditions over a wide range of applications. Engineered plastic bearings are made from thermoplastic bearing material processed by injection moulding. This production method enables us to produce unlimited dimensions in accordance to our standard, and also parts with special designs and features.

Aurora ANC-3TG crosses available at National Precision Bearing. Aurora ANC-3TG equivalent to National Precision Bearing MS14101-3.

Radial loadbearing

Tribology is the science of wear, friction and lubrication, and encompasses how interacting surfaces and other tribo-elements behave in relative motion in natural and artificial systems. This includes bearing design and lubrication.

Obviously, this is an extremely dangerous situation. It can cause a complete loss of control and a high chance of injury.

As bearings wear, they create more noise. The noise from a wheel bearing will be a constant droning or scraping noise and is the best way to tell if there is a problem.

If it's too difficult to tell, especially with how well sound-insulated modern cars are, a passenger can try listening to the noise from the front and then rear seats.

Axial loadbearing

Our package allows you to replace all the components designed to work and fit together to the optimum conditions, while at the same time, increasing sales and ...

Sep 29, 2022 — Parts to Know When Replacing Your Vehicles Wheel Bearings & Hub Assembly. As you can see in the image above, the key parts of the bearing and ...

At GGB, we aren’t afraid to take risks for our customers. We are passionate about the work we do and believe that same passion contributes to the level of innovation that can enhance human potential. We take pride in working closely with customers in the early stage of a design to think broadly and boldly, and to expand beyond traditional surface engineered solutions. We offer reliable partnerships based on trust, compassion, determination, collaboration and respect.

GGB thrust washers and flanged thrust washers are offered for applications with heavy axial loads. These washers are available as a special form of our popular plain bearings including DP4® and DU® self-lubricating bearing materials.

Split the cost of car repairs into monthly payments with Bumper. Apply online before your visit and choose from lots of garages already on the Bumper network.

Joseph has been writing about cars for over seven years and writing for Bumper for over two, blending his passion for automobiles with a talent for storytelling.

So, if you’re wondering if wheel bearings are expensive, the price ultimately comes down to which specific parts your car needs.

Wheel bearing replacement is a common issue, so the parts are relatively cheap, and any competent garage well understands the process. Typical parts prices range from £30 to £250, but then you have to include the labour costs as well.

Made with the latest technology and premium materials, these polyester or plastic bowling balls offer optimal precision and control on the lanes. Don't miss out ...

If you can hear a new noise, particularly a droning that increases in volume and frequency with speed, there's a good chance you have a failing wheel bearing.

Bearings are absolutely everywhere in machinery and vehicles. Anything with moving parts will always have a bearing of some kind. Car wheels require strong and precise bearings to cope with the large forces of bumps and turns.

You can estimate your wheel bearing cost depending on the type you buy. Here’s a quick overview of the different price brackets:

When a bearing completely fails, the hub nut can no longer stop the outer bearing race, hub and wheel from sliding off the axle. In short, the wheel can literally fall off the car.

Axial vs radial loadformula

Like many components on a car, wheel bearings almost always give plenty of warning, audible and otherwise, that they’re starting to fail. Also, like other parts, the consequences of allowing one to fail can be severe.

Because a bearing's job is to reduce friction, when they’re not working as they should, more friction and therefore heat is generated. This can often be felt on the wheel after a long drive.

... India.For more details about NSIL, click here. BUSINESS [WHAT WE DO]. PSLV production. NewSpace India Limited (NSIL) will be nodal agency for carrying out ...

Split the cost of car repairs into easy monthly repayments with completely interest-free car repair finance. Find a Bumper partner near you.

Not only can this cause a wayward steering feel, but it can also wear out your front tyres faster. If your car feels like this when steering and shows other signs of a worn bearing, get it checked as soon as possible.

Radial loadformula

While a mechanic will be best placed to properly diagnose your wheel bearing issues, there are some symptoms to look out for. Here are four signs drivers need to know:

GGB cylindrical bearings, with their high load capacity, are designed to support large radial loads. Our Fiber Reinforced Composite Bearings are especially apt for these applications with load capacities up to 415MPa.

Typically it is cheaper to replace a bearing on a non-driven axle, as there are fewer components to remove, with most cars being front-wheel drive (except for many BMW and Mercedes cars) this means the rear bearings are cheaper.

Wheel bearings are considered a standard wear and tear item on a car. Depending on the number of miles you drive and how long you keep a car, you should expect to have to replace them at some point.

Be careful when touching any part of the wheels as they can become very hot depending on the severity of the bearing issue and if you have been braking hard. But if one wheel is slightly warmer, this could indicate a bearing problem.

Axial bearings, or thrust bearings, are designed to withstand force in the same direction as the shaft. This is called an axial load, or thrust load.

If you hear an unfamiliar noise when drifting to the left, there may be a problem with your right wheel bearing. If the noise occurs when you drift right, the left wheel bearing may be faulty.

2017513 — The OEM wheel bearings Honda uses are mostly made by NTN. You can get them in NTN boxes for cheaper than Honda boxes. Another brand Honda uses for OEM is Koyo.

Radial ball bearings are designed to withstand forces that are perpendicular to the direction of the shaft, or radial loads. Radial bearings are the most common type.

Shop for the best Bearings & Seals for your vehicle, and you can place your order online and pick up for free at your local O'Reilly Auto Parts.

When doing an MOT, the tester will lift your car and firmly pull on the wheels in various directions. Excess movement in the wheel, when pulled from the top or bottom, is usually a symptom of a failing wheel bearing.

Bimetal and metal bearings offer excellent corrosion resistance in industrial outdoor applications and in water, marine and offshore environments. GGB offers a broad range of sizes, forms and materials in monometallic and bimetallic bearings.

However, life expectancy depends on how often you drive and the condition of the roads you drive on. This may mean wheel bearings need replacing sooner or later, but they won’t need replacing regularly.

The wheel hub - the part that the wheel bolts to - is held in place by the hub-nut, which prevents the wheel and hub from coming off the axle.

This can start to happen because the wheel bearing ensures the wheels are rotating in a single plane and not moving side to side when the bearing wears out.

GGB's diverse polymer coating solutions encompass some of the most state-of-the-art coating technologies available. Our TriboShield® product line includes seven standard formulations that cover the full spectrum of mechanical, thermal and chemical capabilities offered by today's coating materials. They can also be applied to nearly any surface, regardless of shape or material, making their potential almost endless. And when it comes to working with and enhancing the performance of your existing bearing and polymer coatings solutions, our TriboMate product line is specifically designed to be paired up— all leading to enhanced performance.

Some ball bearings are able to withstand a radial and axial load applied on the shaft, these combined axial/radial load bearings are achieved by axial angular contact. The angle of these axial radial bearings allows the axial load and the radial load to be distributed more evenly along the axial angular contact ball bearing.

Engineered as a solution to conquer misalignment reduction when high demands are placed on bearings, GGB's UNI, MINI and EXALIGN® self-aligning shaft bearing assemblies offer improved equipment performance under standard bearing assemblies by reducing stress and friction. Offering superior performance in a wide variety of applications, GGB's self-aligning assemblies are available in both standard and custom configurations.

8613869596835

8613869596835